Audemars Piguet

The Varied Constructions of Vertical Clutch Chronographs

On the other hand, vertically coupled chronographs are where things get a little misty, not only because the mechanism is typically obscured from view by an oscillating mass, but also because their compact system allows room for more variation in movement design. But before moving further, it is worth revisiting the cornerstones of a vertical coupling system.

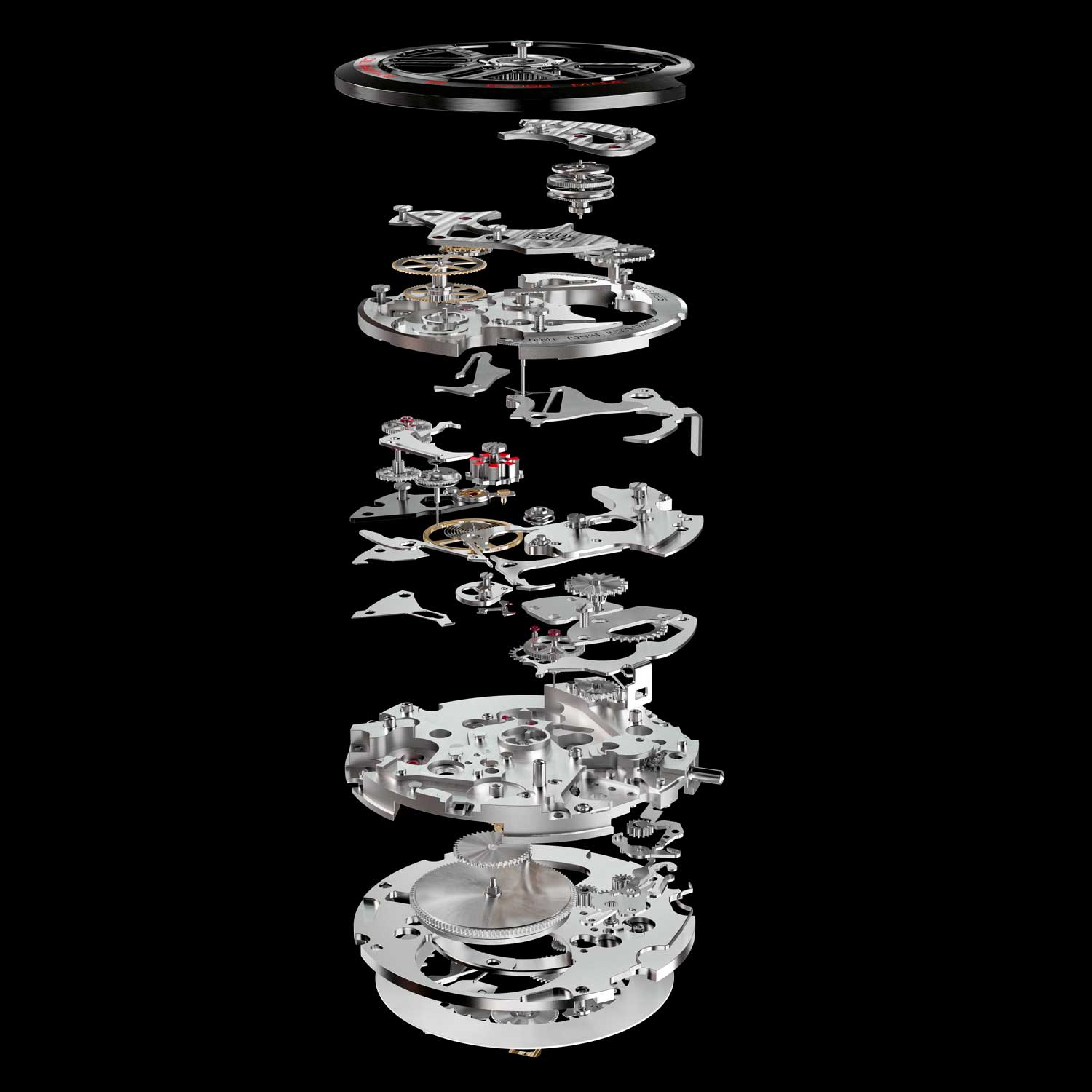

An exploded view of TAG Heuer’s HEUER 02 chronograph movement, which employs a column wheel control and vertical engagement formula

Vertical Clutch System

Vertical clutches are of a co-axial structure in which the chronograph seconds wheel and drive (or fourth) wheel are located concentrically on the same axis. When the chronograph is switched on, a pair of arms releases the clutch, dropping the chronograph wheel onto the running wheel. Both wheels are driven together by friction, causing them to turn in tandem. While the drive wheel is constantly driven by the gear train, the chronograph seconds wheel is stationary when not in use.

In this ideal configuration, there is no meshing of teeth when the chronograph starts or stops as both wheels are already on the same arbor. Hence, vertically coupled chronographs, in theory, do not suffer from seconds-hand stutter during engagement, which is a key advantage over a horizontally coupled chronograph. At the same time, because all wheels are superimposed on the same axis in the center, essentially within the gear train, there is minimal impact on balance amplitude during engagement.

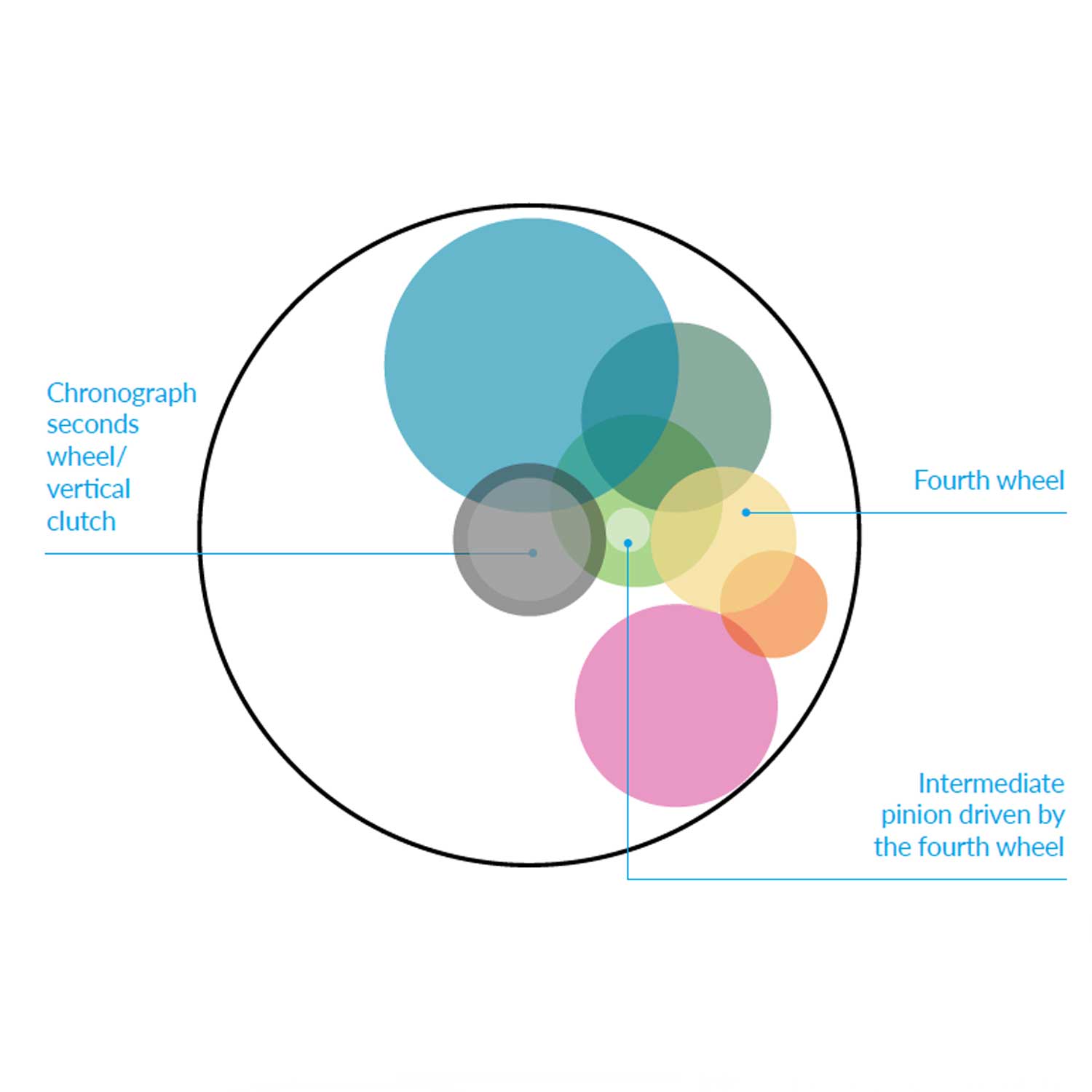

However, due to the many possibilities in gear arrangement that this system permits, the renowned advantages of a vertical clutch system are preserved in some but not others. In fact, these broad theories only apply if all three components — fourth wheel, vertical clutch mechanism and chronograph seconds wheel — are stacked vertically in the middle of the movement so that there is no additional meshing of gears involved. In the event where the fourth wheel is located elsewhere to drive a running seconds counter directly, an auxiliary train is necessary to connect the fourth wheel to the chronograph wheel in the middle. This horizontal mating of gears in turn reintroduces the issue of backlash, caused by gaps between meshing teeth, necessitating other solutions such as a tensioner to reduce flutter, in which case the smooth action of the chronograph seconds hand is no longer an inherent advantage of a vertical clutch system.

But perhaps the real surprise is that a directly driven vertical clutch mechanism happens more rarely than we think, particularly in modern movements where the thinness of the movement takes precedence. More pertinently, this ensemble offers a glimpse of just how widely the basic architecture of vertical clutch chronographs can vary in contrast to their horizontally coupled counterparts.

TAG Heuer Monaco

TAG Heuer Caliber Heuer 02

The TAG Heuer 02 was first introduced in the Autavia Heritage in 2017. In contrast to the Heuer 01 caliber, which utilized an oscillating pinion, it incorporated a vertical coupling system. Its three-register, fully integrated architecture offers impressive power reserve of up to 80 hours on a single barrel and has a beat rate of 28,800vph. It measures 31mm in diameter and notably, just 6.9mm in thickness.

TAG Heuer Caliber Heuer 02

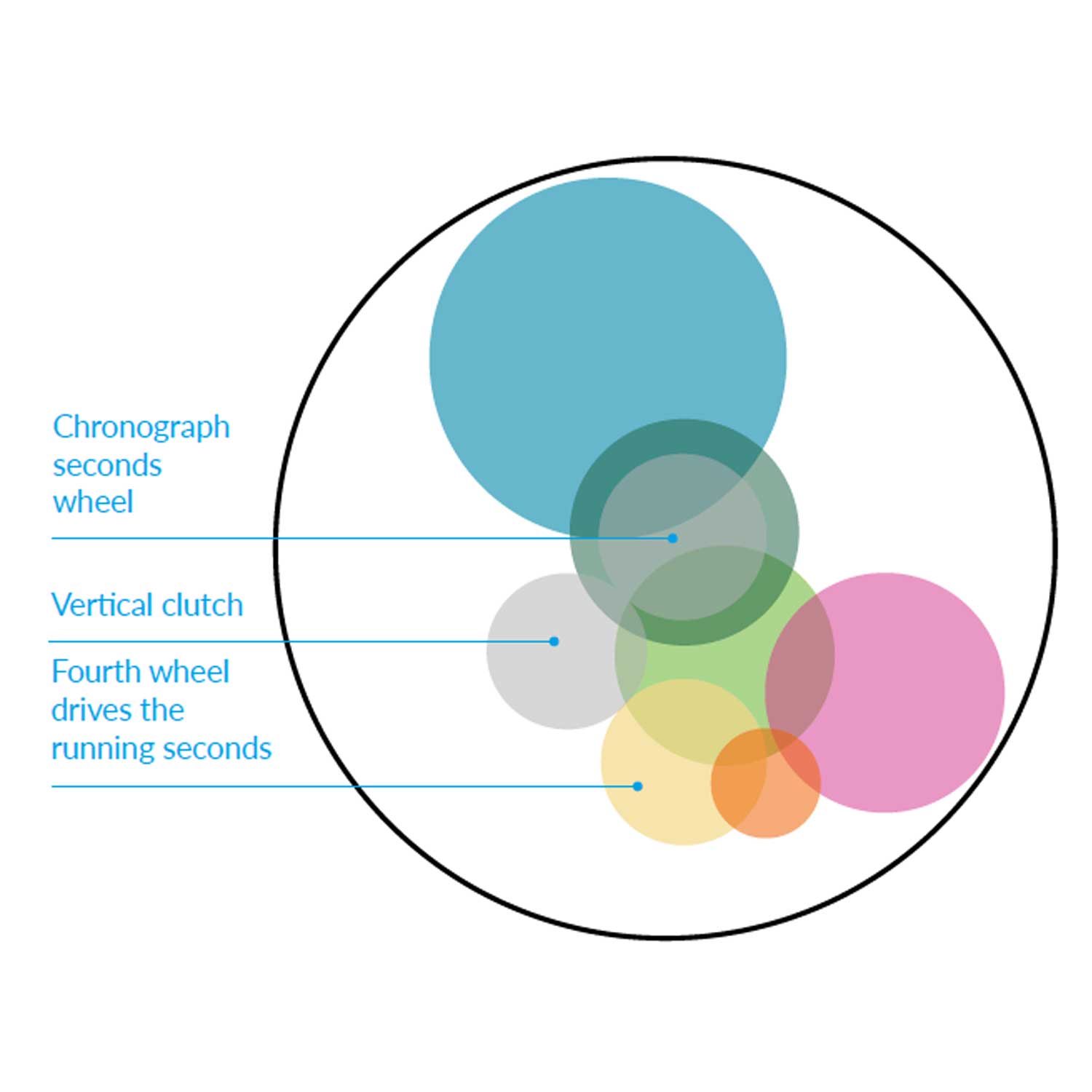

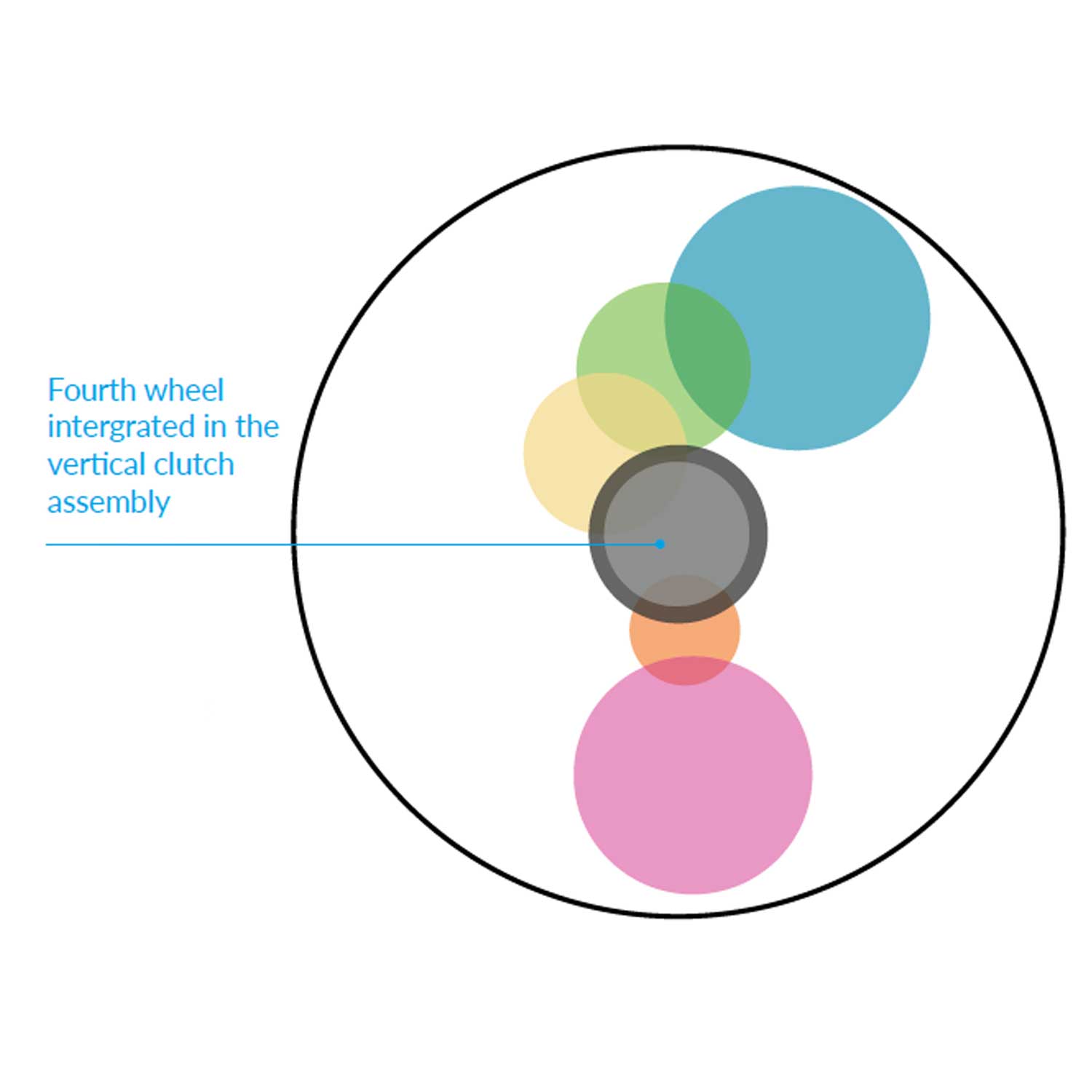

A diagram of its gear train, vertical clutch and chronograph seconds wheel

Dark Side of the Moon Co-Axial Chronometer

Omega Caliber 9900

In 2016, Omega introduced the METAS- certified Master Chronometer caliber 9900, which replaced the caliber 9300 launched in 2011. Highly robust in construction, it has a large diameter of 32.5mm and a thickness of 7.6mm, which is just slightly slimmer than a Valjoux 7750. It is loaded with a host of advancements, from DLC-coated barrels to silicon hairspring, not to mention a co-axial escapement, making it the most high-tech vertically coupled chronograph in its price segment. It relies on two serially coupled barrels to provide a power reserve of 60 hours and has a beat rate of 28,800vph.

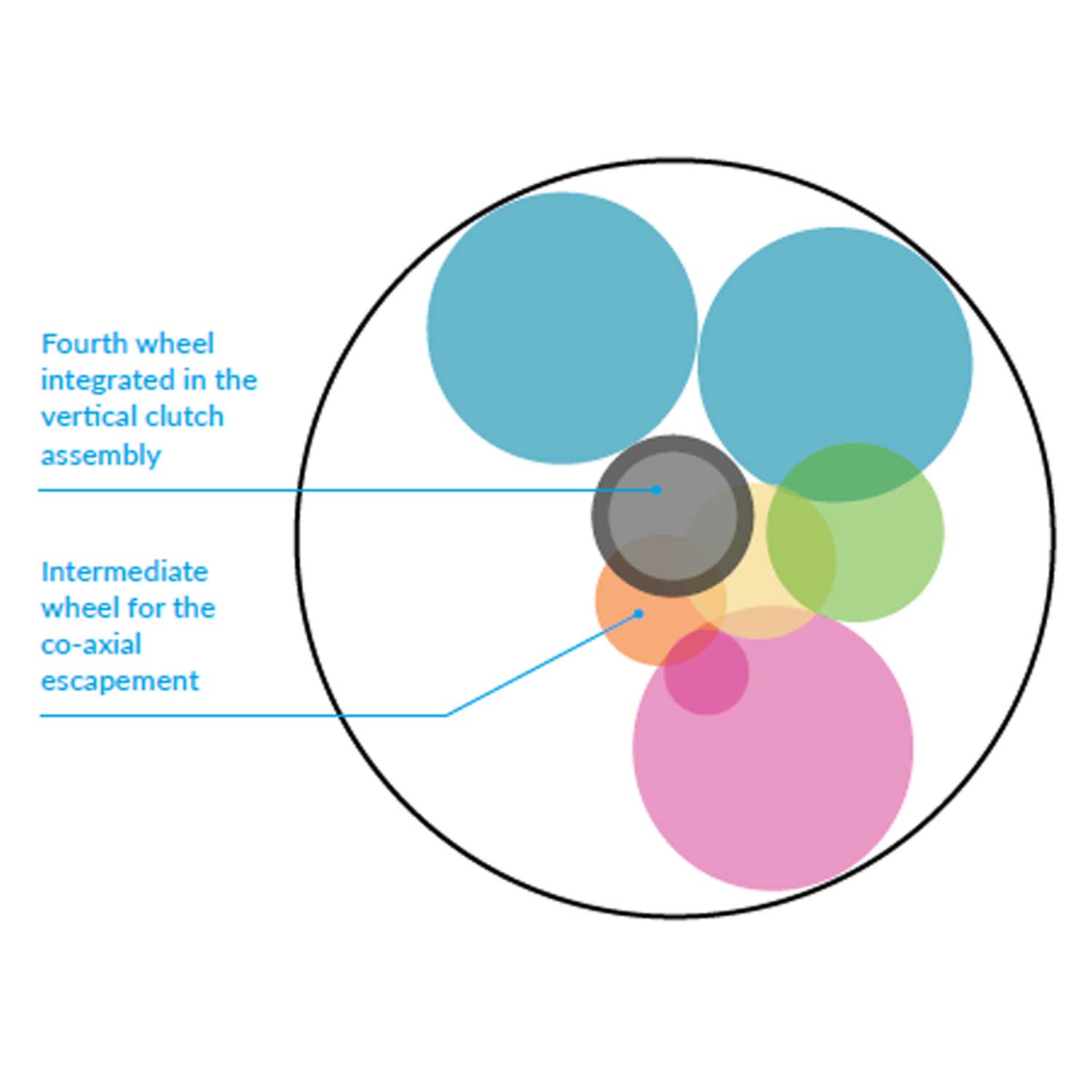

Omega Caliber 9900

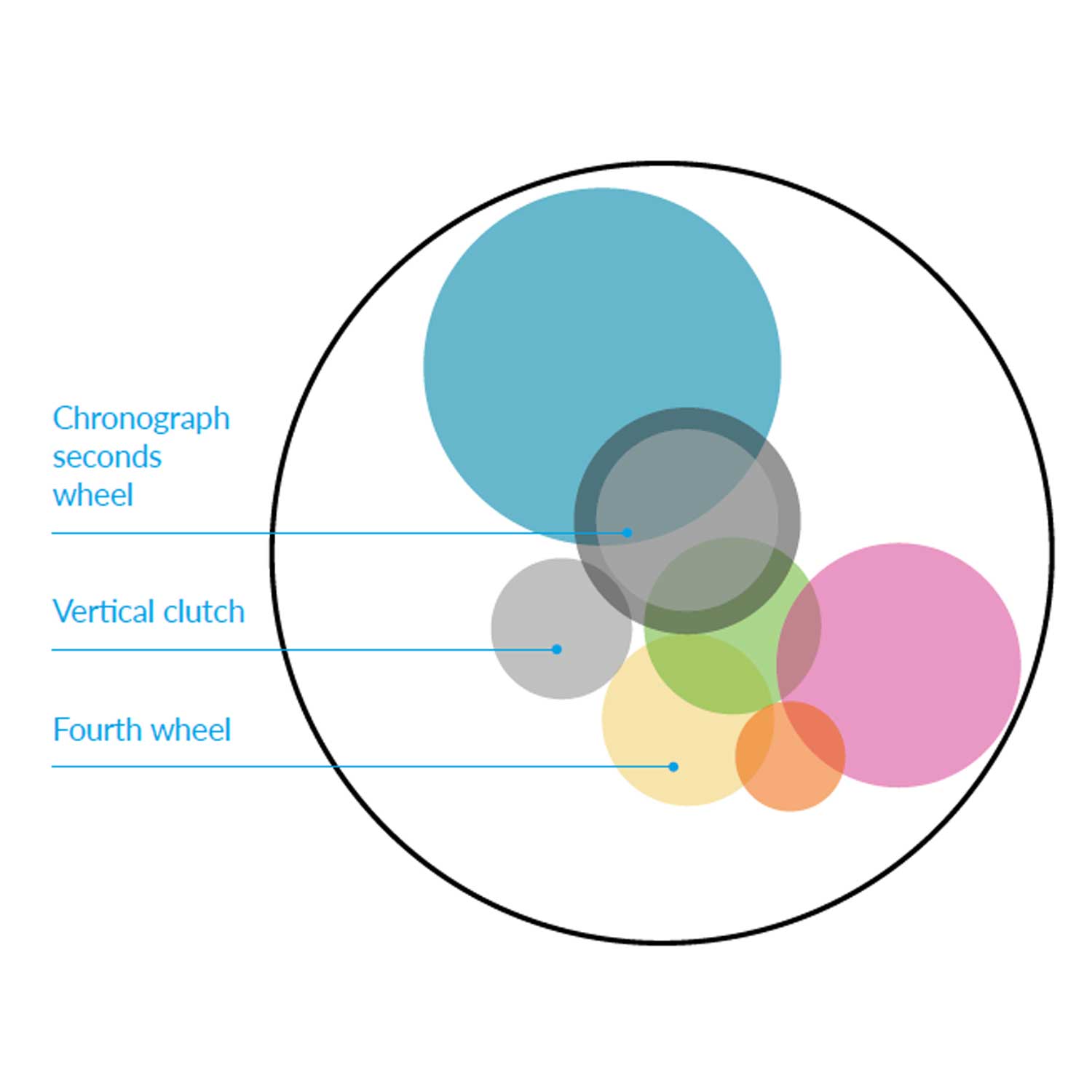

A diagram of its gear train, vertical clutch and chronograph seconds wheel

With the fourth wheel integrated in the vertical clutch assembly, this construction effectively eliminates the jerk of the seconds hand and offers an ultra smooth motion. It realizes the true merits of a vertical clutch, ensuring it functions at its best.

The Aquanaut in white gold with a khaki green (ref. 5968G-010) and midnight blue dial (ref. 5968G-001)

Patek Philippe Caliber CH 28-520 C

The Patek Philippe CH 28-520 C, introduced in 2006, was Patek’s first in-house chronograph movement. It was used in the Nautilus ref. 5980 and, more recently, the Aquanaut ref. 5968. At just 6.63mm in thickness, it was designed to accommodate a variety of complications while retaining a slim profile. Its modest dimensions are attributable to its straightforward construction as it omits a running seconds counter. Instead, it features a single elapsed minute counter (with co-axial hour scale in the case of the Nautilus) at six o’clock.

Patek Philippe Caliber CH 28-520 C

A diagram of its gear train, vertical clutch and chronograph seconds wheel

As such, this ideal configuration allows the chronograph to function efficiently and is particularly suited for such a dial design as it facilitates the use of the chronograph seconds as an active running seconds with negligible impact on amplitude. When the chronograph is switched on, the chronograph seconds wheel drives a chronograph minute wheel via an intermediate wheel.

The CODE 11.59 Selfwinding Chronograph

Audemars Piguet Caliber 4401

Launched in 2019 in the CODE 11.59, the caliber 4401 is Audemars Piguet’s first in-house chronograph movement. While it is quite a large movement, measuring 32mm wide, it is notably slim at just 6.8mm high. It is classically solid in construction, offering a power reserve of 70 hours and has a beat rate of 28,800vph.

Audemars Piguet Caliber 4401

A diagram of its gear train, vertical clutch and chronograph seconds wheel

This layout frees up space in the central portion of the movement for the chronograph minutes and hour wheels as well as the automatic winding mechanism, keeping the movement as slim as possible.

Breitling Super Chronomat B01 44

Breitling Caliber B01

Introduced in 2009, the Breitling B01 is a smartly engineered movement with a particularly inventive and sophisticated construction for its price point. In fact, it has the most unusual architecture in this list of automatic chronographs.

The B01 caliber has a diameter of 30mm and is on the thicker side at 7.2mm in height. The layout of its gear train differs dramatically from all other automatic chronographs as the hour recorder wheel was intended to be located at six o’clock so that it can be conveniently removed to achieve a bi-compax dial in certain watches, such as the Premier B01 Chronograph 42 and the Tudor Black Bay Chronograph. As such, the fourth wheel is located at three o’clock to drive the constant seconds directly. But most surprisingly, the second wheel of the movement is not located in the center. Instead, the mainspring drives the motion works directly on the dial side. This is to ensure the entire gear train only occupies the right side of the movement, leaving a large expanse on the left for the chronograph mechanism. At the same time, this allows the entire chronograph mechanism to be designed as a single unit, which can be conveniently removed during servicing.

Breitling caliber B01 seen through the sapphire caseback

A diagram of its gear train, vertical clutch and chronograph seconds wheel