An intelligently designed asymmetrical dress watch through and through.

One of the most intriguing time-only watches that has been in the works for some time now is from Sylvain Berneron, the chief product officer of Breitling. The 34-year-old French designer has spent the last 15 years working for leading automobile marques including BMW, Porsche, Ducati, followed by roles at IWC and, subsequently, Breitling. Having served as the creative director at Breitling for the past five years, he was recently promoted to chief product officer. All while holding the creative reins at the brand, he had also started pursuing his own independent project with the green light from CEO Georges Kern, which is something that doesn’t happen all that often in the watch world.

Sylvain Berneron

For his first timepiece, Berneron set out to take on the challenge of creating a slim and asymmetrical dress watch with a high-performance shaped movement. The Mirage is an example of the level of engineering that can arise in the pursuit of not one but three distinct goals that aren’t normally attained simultaneously in the same watch due to their inverse nature. Historically, shaped dress watches tend not to have a shaped movement due to its high cost in manufacturing and low frequency of usage, and when they do, performance is necessarily, subordinated to slimness, shape, and size.

A collector himself, Berneron has expressed a fondness for two different categories of watches: the classic form of dress watch such as the Patek Philippe Calatrava, the Vacheron Constantin Patrimony and the Lange 1815 and shaped watches that represent a form of classy subversion such as the Cartier Crash and the Patek Asymétrie. However, he believes that the classic dress watch, despite being constructed to a very high level, is too rigid for daily use while shaped watches, despite offering more latitude, often come with a solid case back that hides a prosaic movement. His goal, ultimately, was to combine the finest aspects of both, yet the result is manifestly far greater than the sum of its parts. On top of that, the Mirage is a full gold watch – the case, dial, hands, base plate, bridges and even the spring bars are made from 18k gold. It was conceptualized and designed by Berneron and produced by a network of specialists based in Neuchâtel.

The Mirage Prussian Blue in white gold and Sienna in yellow gold

According to Berneron, it all began with the design of the movement where he allowed each component to find an optimal place for efficient performance. Most apparently, he broke free from the traditional gear train arrangement, which typically adheres to a logarithmic spiral pattern. Placing the mainspring barrel at 10 o’clock to occupy the most pronounced contour on the base plate allowed for maximum possible size to deliver a 60-hour power reserve. It has a hanging construction, meaning it is only supported on one end, which helps to reduce the overall height of the movement. The gear train is laid out diagonally across the base plate with fourth wheel driving a small seconds at six o’clock on the dial directly. A 10mm balance wheel is located at three o’clock. It operates at a frequency of 3Hz and has an inertia of 7mg.cm2. In effect, he has maximized the available space to optimize the movement’s performance to its fullest potential.

The base plate and bridges are made of solid gold and the movement measures a mere 2.3mm high

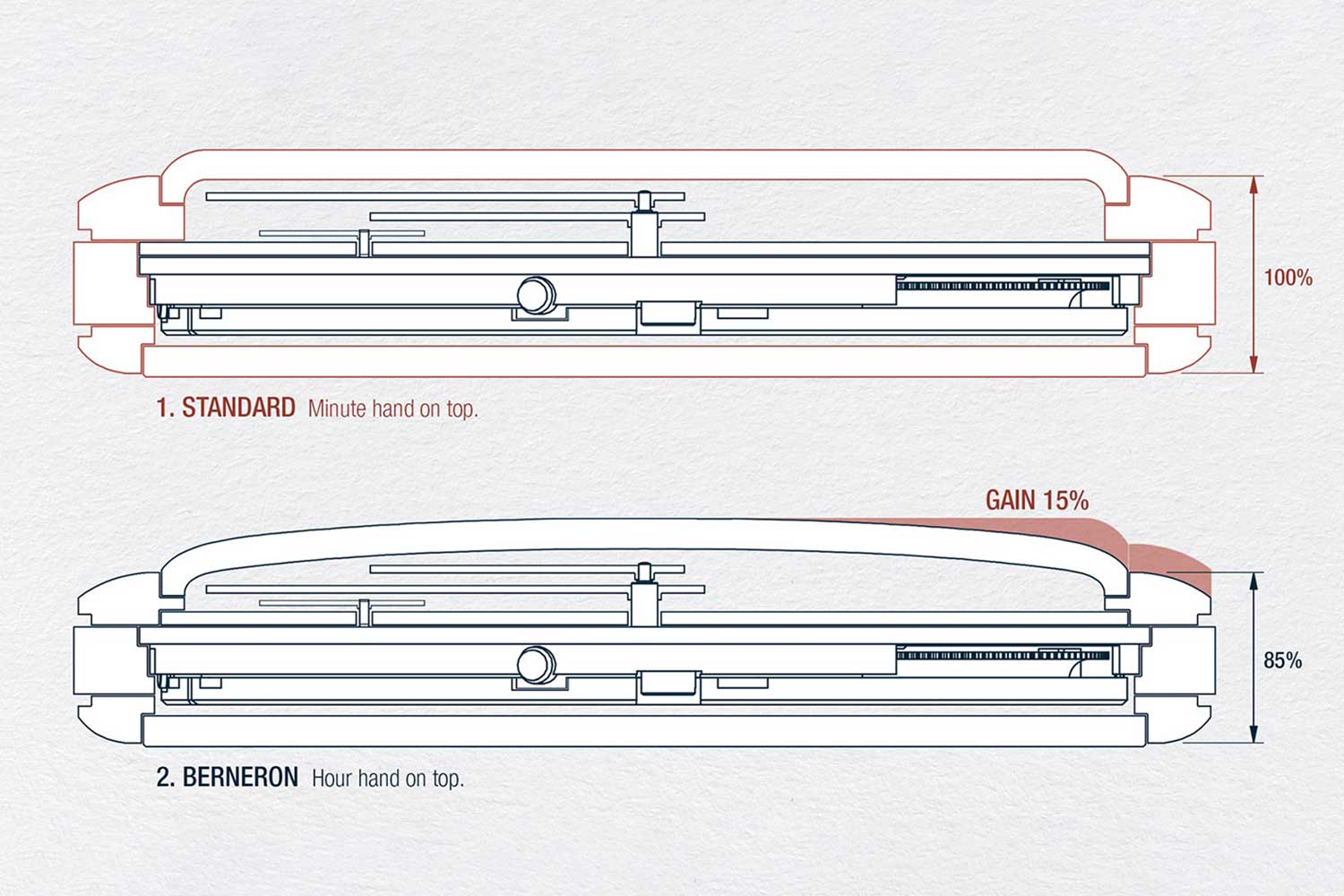

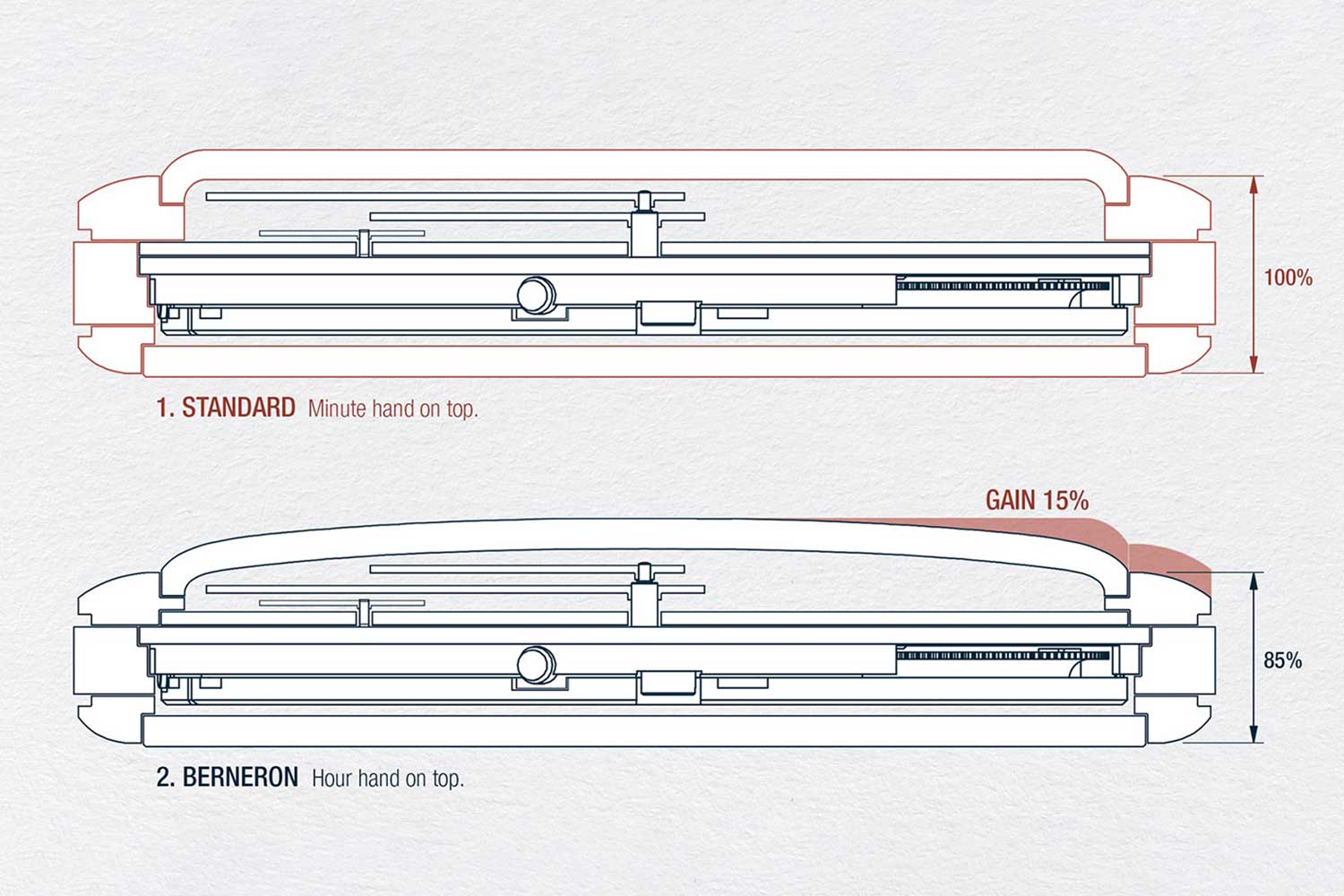

While the use of a shaped movement naturally produces a seamless integration of mechanics and aesthetics, the Mirage goes beyond the obvious way they relate to each other. The movement was designed such that the hand stack is inverted; the hour hand is located above the minute hand on the dial rather than beneath. Given the hour hand’s shorter length compared to the minute hand, this design enables the sapphire crystal to reach the edge of the bezel sooner. It’s a clever way to achieve a slimmer case profile without making concessions to the movement.

A standard watch versus the Mirage with an inverted hand stack

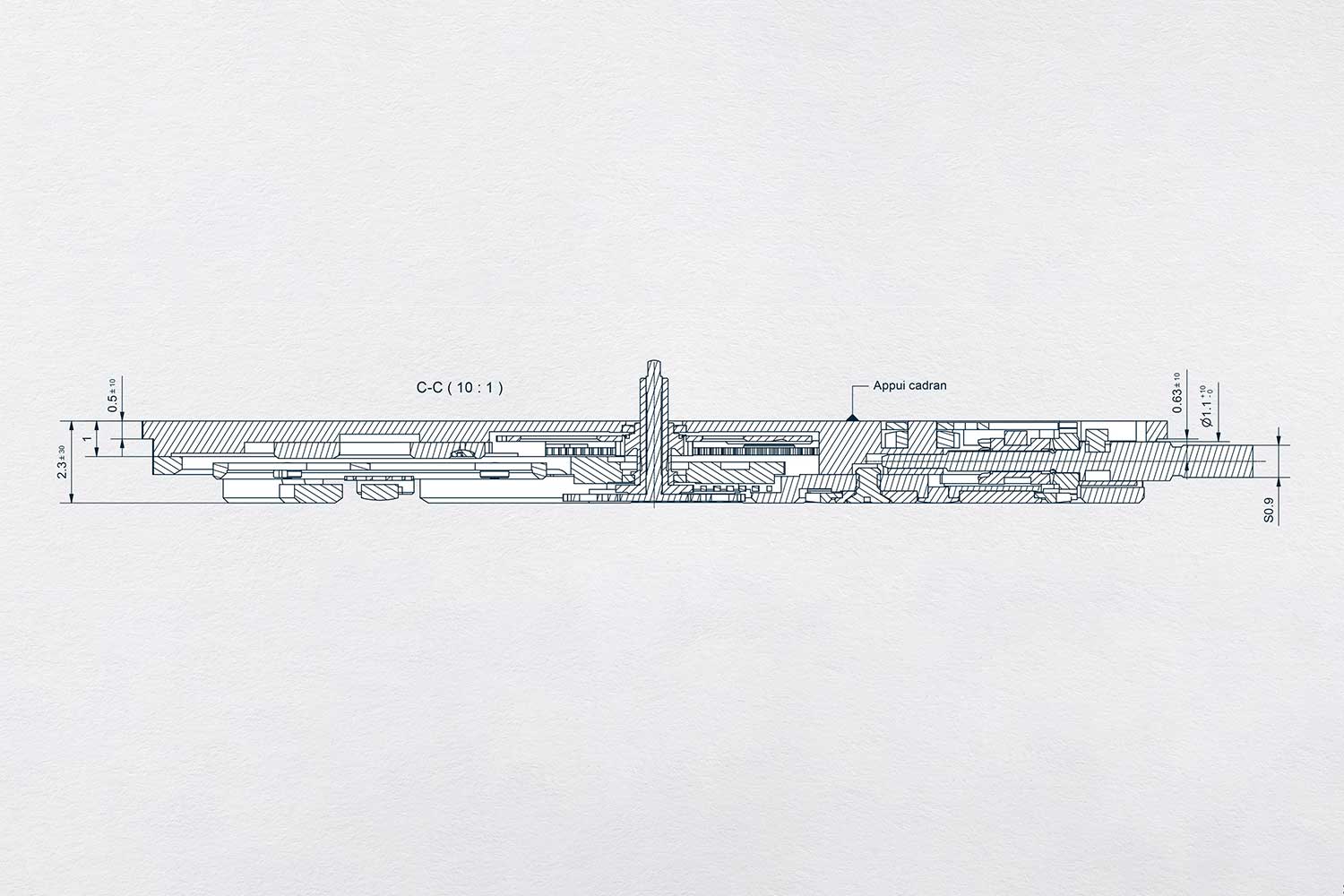

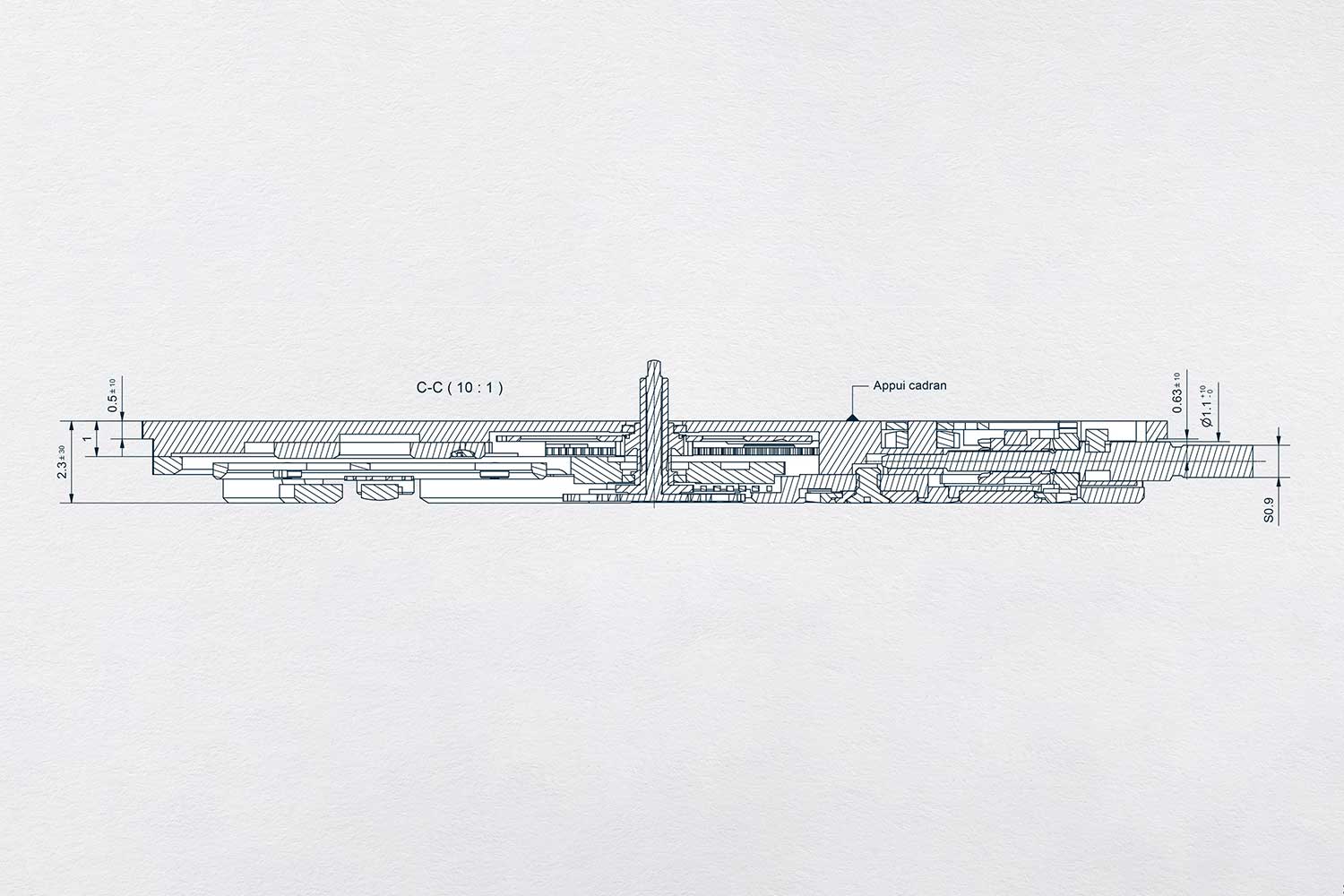

A cross section view of the movement, showing the reconfigured motion works. The hour wheel shaft sits in the shaft of the cannon pinion.

To achieve this, the motion works had been reconfigured to the bridge side of the movement. In a conventional watch, the cannon pinion to which the minute hand is attached, is friction fitted to the centre wheel shaft on the dial side. It drives the minute wheel that carries the minute pinion which in turn drives the hour wheel mounted on the cannon pinion. However, in the Mirage, the hour and minute wheels are visible on the bridge side and the cannon pinion, which had to be elongated, is fitted before the hour wheel such that the shaft of the hour wheel is inside the shaft of the cannon pinion rather than the reverse. While it is simple to explain at the end of it all, it no doubt took considerable thought to arrive at this solution.

Visible at the center is the hour wheel with a perforated spiral pattern.

The hour wheel is on the same plane as the barrel ratchet wheel and the movement clocks in at a height of just 2.3mm high. The balance wheel is made of titanium with four gold regulating weights at its periphery for fine-tuning of the oscillation of the balance but beat error can also be adjusted with the stud adjuster. The movement was developed by the complication specialist Le Cercle de Horlogers. With the exception of the escape wheel, pallet fork and hairspring which were supplied by Atokalpa, all components in the movement had to be designed and produced from the ground up.

The base plate and bridges are made of 18k gold – white gold for the barrel bridge and the fourth wheel bridge while the base plate and the individual bridges for the centre wheel, escape wheel and pallet fork are made of yellow gold. Although gold has a long history in the construction of movements, its application in ultra-thin movements poses greater challenges. Due to its softness relative to materials such as brass or German silver, it is difficult to maintain the desired thinness without compromising structural soundness. The base plate and bridges had to be made as thin as possible while ensuring structural robustness and this achievement marks the production of the slimmest gold movement available today.

An overview of all 135 components and the various finishes employed

Additionally, CNC (Computer Numerical Control) machines that are used for producing brass movements must be thoroughly cleaned before working with gold to prevent any contamination. Given that gold is a precious metal, any contamination or impurities from the brass can result in imperfections, affecting the quality and integrity of the final gold components. On top of that, should errors in machining occur, gold has to be carefully handled and recycled in a controlled manner to maximize its reuse. Brass, on the other hand, is a widely used alloy with lesser intrinsic value, making its disposal and recycling less stringent. As a result, the cost of producing a gold movement is significantly higher.

The gear train is made of brass, whereas the winding wheels are machined from steel to withstand higher torque, and the balance wheel is supported by a traversal bridge crafted from steel for enhanced stability. In terms of decoration, the parts are finished using a variety of techniques. The base plate and the centre wheel bridge have a frosted finish while the white gold bridges are decorated with a guilloché pattern that resembles Geneva stripes. Initially, Berneron had planned to use a traditional rose engine to manually apply guilloché to the bridges and the barrel rachet wheel. But this proved unfeasible due to the delicate nature of the ratchet wheel, which has a thickness of only 0.3mm and required three times its dimension to withstand the machining process. Additionally, the use of gold for the bridges meant that it would risk deforming under excessive stress. Thus, the engraving on the bridges is executed using CNC which can offer stability with its automated and controlled movements, while the barrel ratchet wheel is laser engraved with a motif of a pinecone.

The white gold bridges feature a fresh take on Geneva waves, executed in guilloche

The pinecone motif, its arrangement of the bracts, reflects the mathematical principles of the Fibonacci sequence which has inspired the shape of the watch and movement. The perforated dotted pattern on the hour wheel was also derived from the Fibonacci sequence, originating from a dotted spiral structured around Fibonacci numbers, but the starting dots were removed, resulting in a simplified version that retains the essence. While the renderings cannot accurately reflect it, the anglage on the bridges will be executed by hand using manual files.

The Mirage is offered in two versions – the Sienna in yellow gold and Prussian Blue in white gold. Berneron has taken a stance to never produce a steel watch for two reasons. He would like to preserve the rarity of the watch, not just in terms of quantity but also intrinsic value. Secondly, he emphasizes gold’s longevity, being less prone to tarnishing and corrosion, requiring less frequent polishing to maintain its lustrous appearance, and should the case be severely damage, skilled goldsmiths, not just casemakers will be capable of refurbishing it.

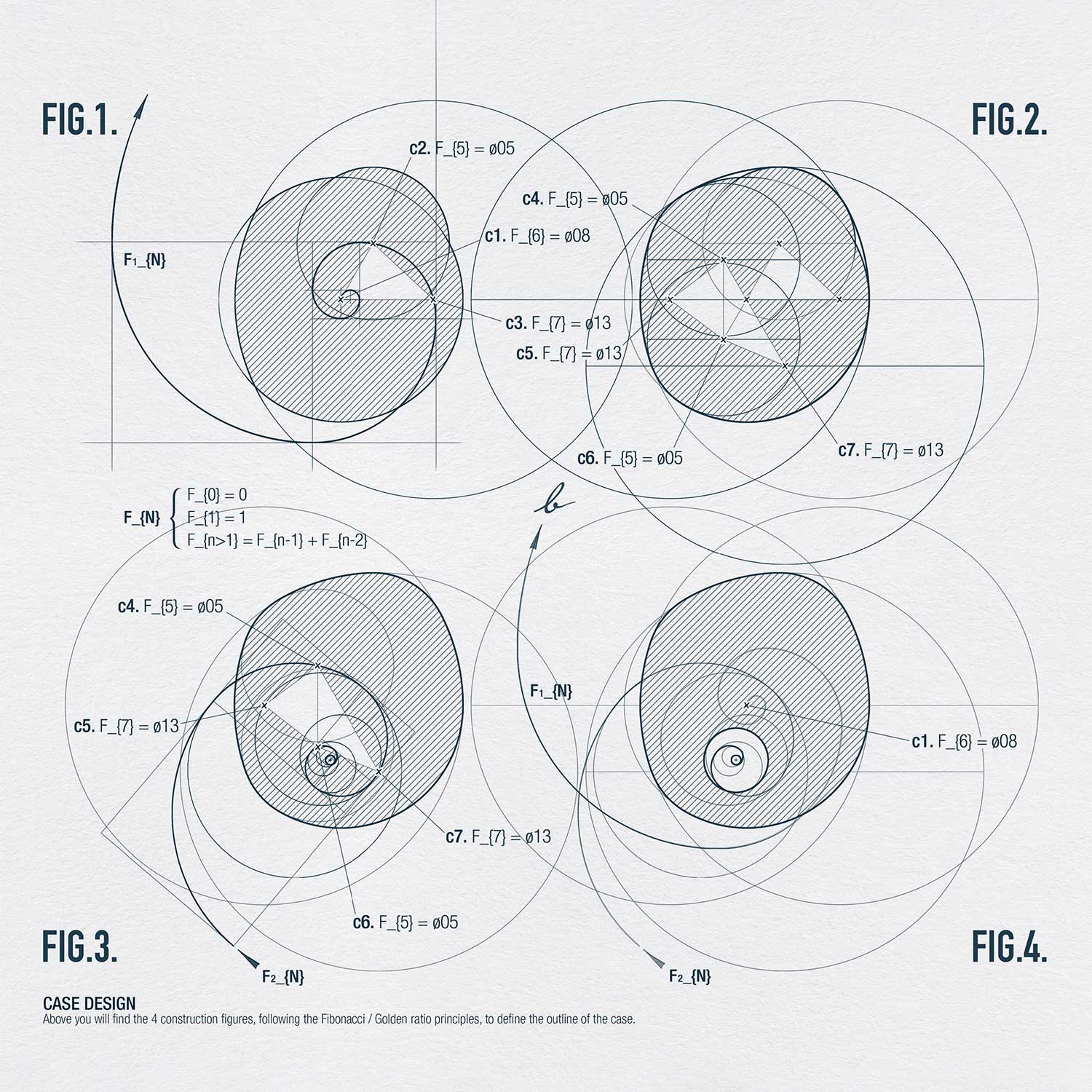

The case measures 37.5mm in length, 33.5mm in width and 7mm high. Its shape resembles a pebble that seems to have been drawn freely but it was actually derived from the Fibonacci sequence. In fact, the underlying principles behind its formation is particularly fascinating.

The Fibonacci sequence is a series of numbers where each number is the sum of the two preceding ones. It typically starts with 0 and 1. So, the sequence goes 0, 1, 1, 2, 3, 5, 8, 13, 21, and continues infinitely. The sequence is credited to the Italian mathematician Leonardo of Pisa, known as Fibonacci, and was first introduced in his 1202 book “Liber Abaci.” Fibonacci’s work not only laid the groundwork for the adoption of the Hindu-Arabic numeral system in Europe but also demonstrated the practical application of the sequence through a problem concerning the growth of a hypothetical rabbit population. This sequence’s pervasive presence in nature has fascinated mathematicians and scientists, finding manifestations in various biological settings, from the arrangement of leaves on a stem to the breeding patterns of rabbits. Its enduring impact spans multiple fields, including botany, biology, and financial markets.

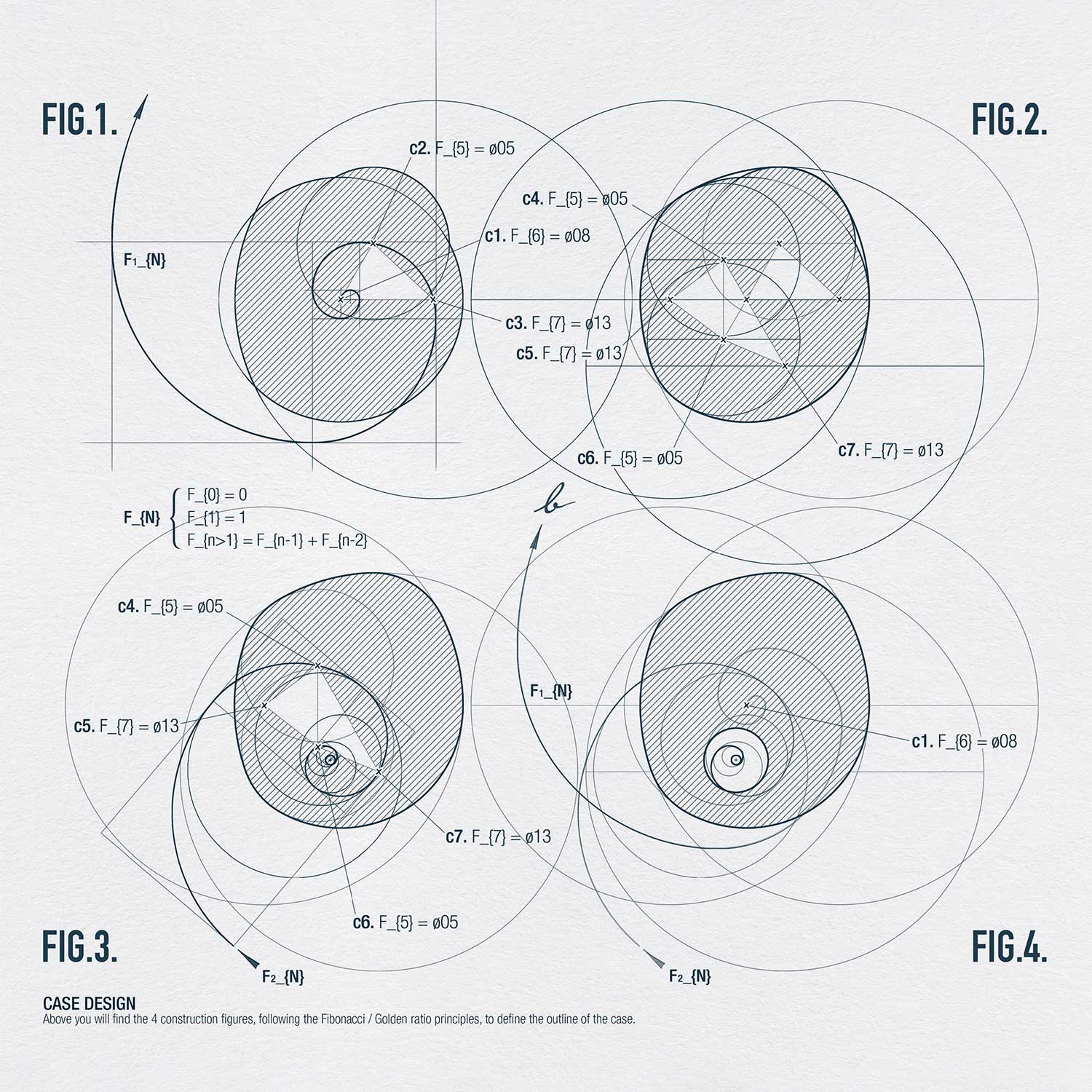

Interestingly, Berneron employed the mathematical principles of the Fibonacci sequence and the geometric properties of a circle to derive a form that exhibits irregularity and an organic elegance. The diagrams below show exactly how he derived the unusual shape. He starts off the process with the circular shape of a conventional watch case, as depicted in Fig. 1, and proceeds to incorporate a Fibonacci spiral emanating from the central axis. In Fig. 3, an additional spiral is introduced, with its origin positioned at the central axis of the sub-dial. Both the smaller and larger circles are generated from the points delineated on both spirals. To ensure the watch maintains a practical size for wear, Berneron consistently adheres to the Fibonacci numbers 5, 8, and 13. Ultimately, the final shape arises from the intersection of these circles.

Four drawings showing the intriguing way the shape was derived using Fibonacci numbers.

The case has a wide polished bezel that emphasizes its unusual shape while the case band has a satin-brushed finish. For the dial, Berneron chose a sector design as he found that its precision and rigidity invited the most intriguing opportunity for distortion. He also designed his own typeface. Designing an asymmetrical dial for accurate time reading is no easy feat. The Crash had to be taken apart and have its dial repainted multiple times to get the placement of the numerals right and even then, due to its wildly distorted shape and numerals, which are marked by straight hands, it can still be confusing when it gets to, say, 6 o’clock or 12.30. In the Mirage, the hands are also curved to match the markings and the 30-second mark on the small seconds sub-dial can also serve as a 30-minute marker. Due to their unusual form, the hands could only be crafted and finished by hand.

The extreme and precise orchestration of the Mirage's organic irregularity is what sets it apart, along with a superbly engineered movement

The Mirage is an exceptionally elegant and striking timepiece, whose beauty seems fortuitous at first sight, yet every aspect of its design has been grounded in logic and rationality. To see a shaped watch with a sophistication in design that permeates all levels of it, from its unique form to its dial, hands and movement, is simply a breath of fresh air.

Only 24 watches will be made a year and production is planned for a decade, after which a new series will be introduced. The first 24 pieces have already been spoken for and are scheduled for delivery in April 2024. Currently, Berneron is accepting orders for the second batch, with 18 units already allocated for 2024 as of the time of writing.

Movement: Manual winding; 60 hours of power reserve; 3 Hz or 21,600 vph

Functions: Hours, minutes and small seconds

Case: 18k yellow gold (Sienna) or white gold (Prussian Blue); 37.5mm x 33.5mm x 7mm, water-resistant to 30m

Dial: 18k gold; satin-brushed and polished

Strap: Traditional straight-cut grained calf leather (top & bottom) with tone-on-tone stitching

Price: 2024 – CHF 49,500; 2025 – CHF 55,000 excluding VAT