An intriguingly designed flying tourbillon watch with an astounding 1,000-hour power reserve.

The first thing that strikes you about the Haute-Rive Honoris I is its lengthy 1,000-hour power reserve, which might be reminiscent of an earlier period in modern watchmaking when brands competed fiercely for the longest power reserve. However, that is the least of what makes the watch unusual. At a quick glance, the Honoris I looks highly traditional, featuring a fluted bezel and a grand feu enamel dial with a classical linear dial layout that ends with the flying tourbillon positioned at six o’clock — only that turning the bezel winds the mainspring, and the wheel at 12 o’clock is not the mainspring barrel but the great wheel, positioned just above a planetary differential. The presence of this differential is necessary because, like the

Ulysse Nardin Freak, the mainspring barrel in the Honoris I occupies the entire caseback and requires power to be transmitted to the gear train while enabling the mainspring to be wound via the bezel. The genius behind this watch is

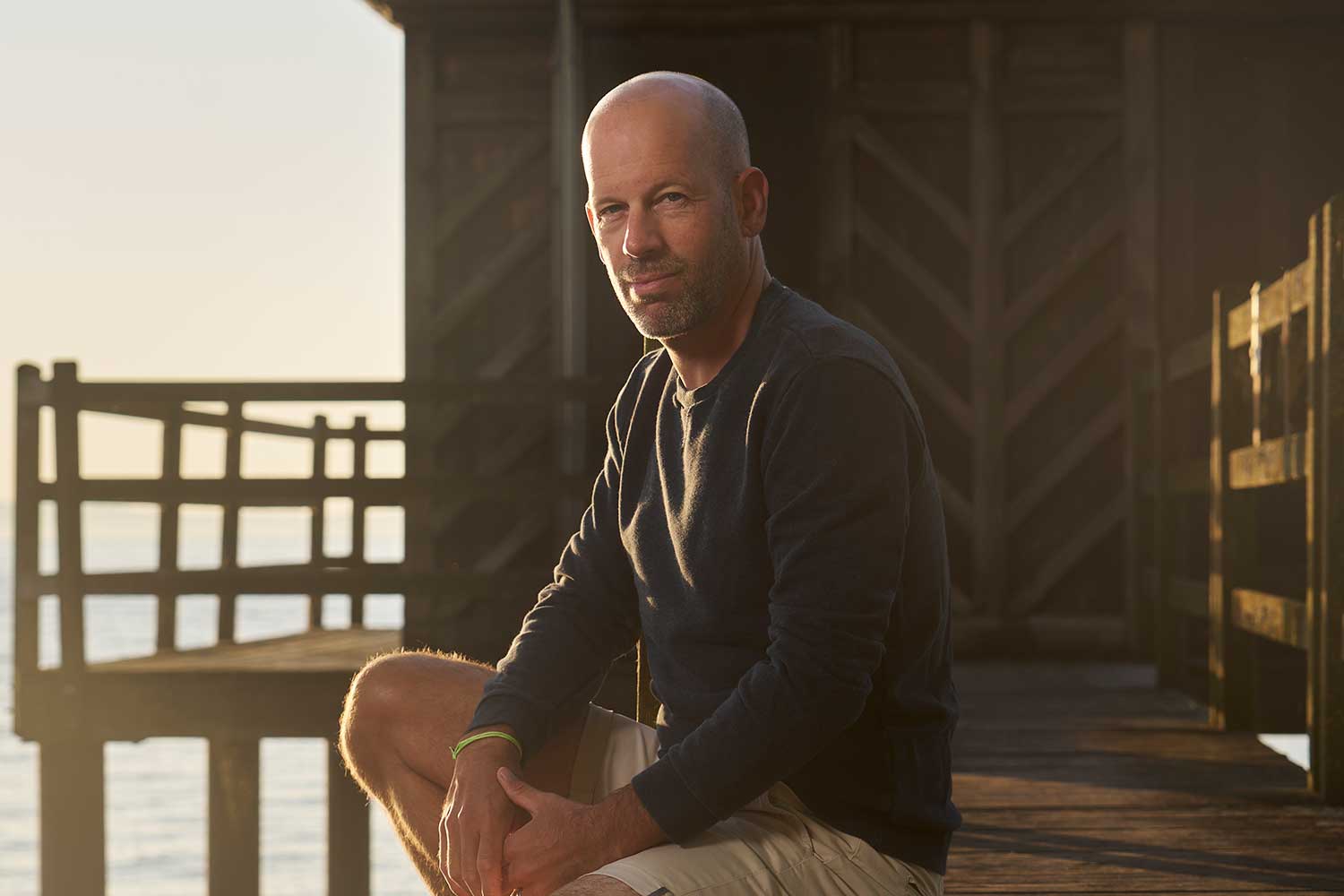

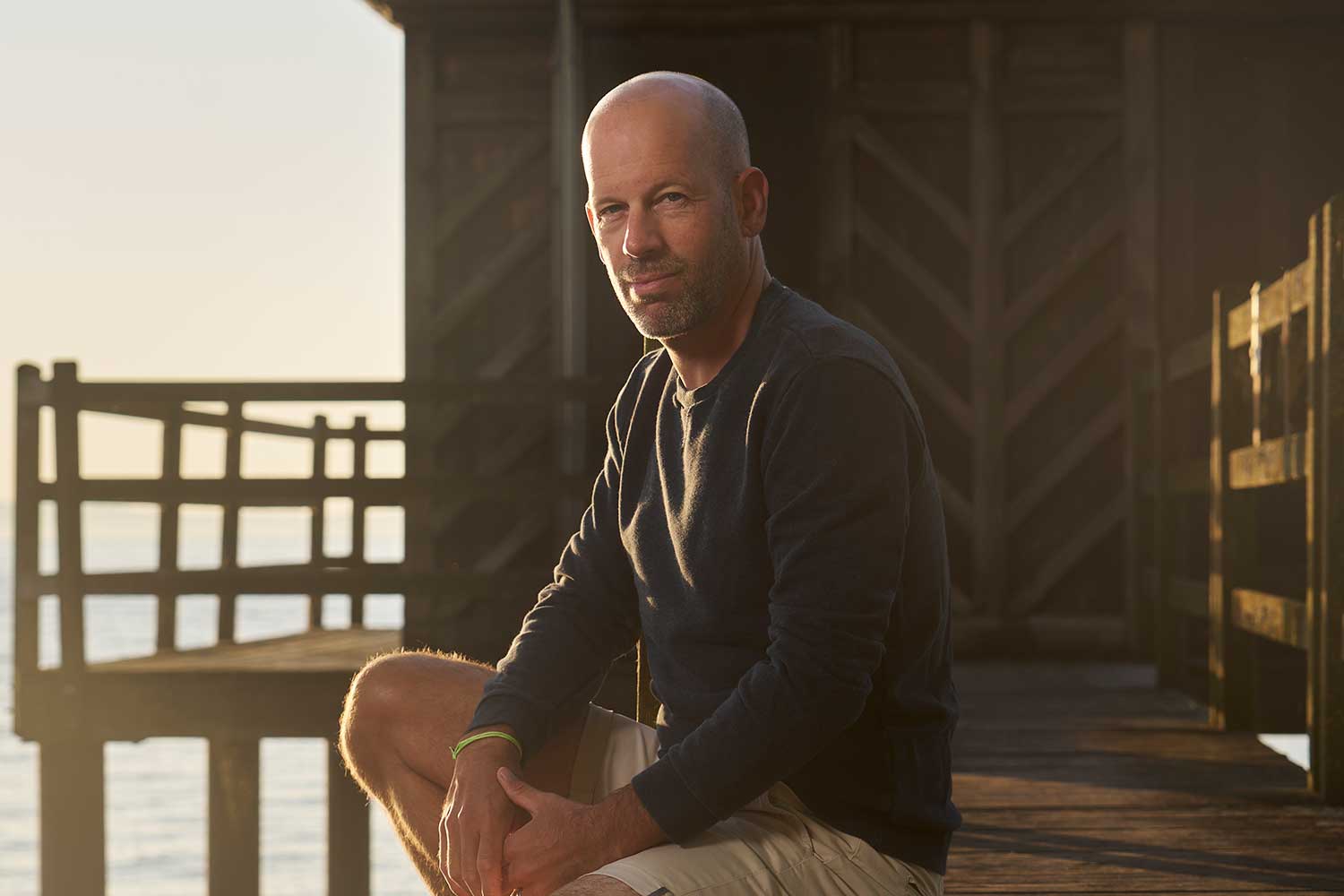

Stéphane von Gunten.

Stéphane von Gunten

Stéphane von Gunten was last known as the director of Research and Innovation at Ulysse Nardin, leaving behind a legacy defined by some 30 patents. He was responsible for a staggering number of innovations that have emerged from the brand since 2007, from the foundational Ulysse Anchor constant force escapement to the revolutionary Grinder automatic winding system. In addition to the numerous Freaks, most notably the

InnoVision 2 and the

Freak NeXt, he was also behind the creation of the

Free Wheel, a cleverly executed watch with its mainspring barrel and flying tourbillon, along with its power reserve differential and indicator, all mysteriously disconnected and suspended above the dial.

In 2021, he became the technical director of the Universo factory in La Chaux-de-Fonds, a facility that produces watch hands and appliques for the rest of the industry. However, by the summer of 2022, he had decided to strike out on his own. He pulled together a group of investors and began engineering his watch movement. Simultaneously, he established a web of suppliers and specialists based in Neuchâtel and diligently oversaw the production process. Before long, Patrik Hoffmann, the former sales director and subsequent CEO of Ulysse Nardin from 2011 to 2017, stepped in to lend his support. Hoffmann assumed a position on the Haute-Rive board of directors, concurrently holding the role of executive vice president at WatchBox.

The mechanics behind the Haute-Rive Honoris I

Like the Free Wheel, the Haute-Rive Honoris I bears an element of mystery because everything in this classically designed watch is not quite what it seems. Unlike the Freak, the mainspring barrel is completely hidden between the mainplate and a cover plate. It houses a three-meter-long mainspring and has a slipping bridle, which is a feature usually found in self-winding movements. The slipping bridle holds the outermost coil of the mainspring by friction to the barrel wall. Once the tension gets too high, the bridle slips, relieving excess pressure from overwinding. As the mainspring barrel occupies the caseback, it provides a natural elevation for all the other components. But to reduce thickness, the motion works, great wheel and flying tourbillon are left above the dial.

A deceptively traditional watch with a highly unconventional construction

The ratchet wheel sits on top of the barrel on the central axis of the movement and drives the differential at 12 o’clock to transmit power to the gear train. When the fluted bezel is wound counterclockwise, it drives a set of pinions at the edge which drives the differential. The differential then winds the ratchet wheel.

The gear train begins with the great wheel (conventionally the center wheel) located above the differential. It drives the cannon pinion directly, which then drives the motion works. A drive wheel meshes with the third wheel pinion offset from the central axis, and the third wheel drives the fourth wheel underneath, just above the ratchet wheel on the central axis. This means that this tourbillon movement can actually be fitted with a central seconds hand.

The planetary differential enables the barrel ratchet wheel to drive the great wheel (conventionally the center or second wheel) and the ratchet wheel to be wound when the bezel is rotated

Cross section diagram of the caliber HR01. The transmission wheel that connects the fourth wheel in the center to the tourbillon wheel (underneath a fixed wheel) has to be slightly inclined

With the fourth wheel stacked above the ratchet wheel on the central axis, the mystery lies in how it drives the tourbillon cage where the tourbillon wheel is on a lower plane as it sits directly above the mainplate and barrel. To solve this, the axle of the transmission wheel connecting the fourth and tourbillon wheel is slightly inclined.

However, there’s more to it. The keyless works have been significantly reduced, as the bezel is used to wind the mainspring. Without the knowledge that the mainspring is positioned in the caseback and wound using the bezel, all of this would seem highly unusual at first glance. As the motion works are elevated above the dial, the winding shaft sits flush within the dial and thus has to be lowered even further so that the crown can sit at the center of the caseband. The winding shaft is thus connected to a winding stem positioned on a lower plane via two pinions. As such, the crown cannot be pulled out.

Thoughtfully engineered, the winding stem is lowered via two pinions to allow the crown to sit at the center of the caseband

Instead of a clutch, the selector pusher linked to a column wheel visible just right above the threaded shaft is used to switch between winding and setting. In setting mode, a circular indicator with a gold finish appears through an aperture on the dial. When the pusher is depressed, the column wheel rotates and a lever carrying the circular gold indicator is pushed out of the pillars, enabling the beak of the pivoted lever to engage with the threaded shaft. This in turn causes the sliding pinion with teeth on its outer surface to engage with the minute wheel, allowing the time to be set. When the sliding pinion is disengaged, the circular indicator is either white or black matching the color of the dial, and the bezel can be wound in the counterclockwise direction to charge the mainspring.

The craftsmanship of the Honoris I

Beyond the intriguing engineering, the movement also showcases a remarkably high degree of finishing with an abundance of inward angles. The 15-spoke great wheel for instance features beveled and polished spokes with sharp internal angles while the intricate shape of the central bridge, which supports the motion works, also lends itself to the most tedious hand finishing. The same goes for the upper cage of the flying tourbillon. Another interesting detail is that the HR logo on the hub of the great wheel always remains upright as it is actually a pivot cover.

Haute-Rive Honoris I

On the reverse side of the watch is a power reserve display where a peripheral ring rotates around a grained central cover to indicate the power reserve. The graduated scale ranges from 0 to 1,000, with each marker denoting 25 hours, equivalent to a little over a day, allowing for easy and intuitive reading.

The 1000-hour power reserve display on the case back. The graduated ring is driven by a large 15-spoke wheel that has also been finely finished

The Honoris I measures 42.5mm wide and just 11.95mm in height. It is available in either white or yellow gold with a black or white grand feu enamel dial, respectively. The enamel dials are made by 2b8 a small supplier of high quality parts and dials in Neuchatel. The traditional aesthetic of the watch is further enhanced by polished leaf-shaped hands that are white gold to match the white gold case or flame-blued steel on the yellow gold version.

Haute-Rive Honoris I in yellow gold with a white grand feu enamel dial

White gold with a black grand feu enamel dial

While the white gold version might seem like the subtler, more naturally appealing option, the yellow gold version with its profoundly traditional façade, ironically takes the subtlety even further as it offers a stronger disguise for all the unconventional mechanics. In conception, execution and effect, it is painfully clever.

Tech Specs: Haute-Rive Honoris I

Movement: Manual winding caliber HR01; 1,000-hour power reserve

Functions: Hours and minutes

Case: 42.5mm; 18K white or yellow gold; water resistant to 30m

Dial: Openworked, black or white grand feu enamel

Strap: Handstitched black or brown nubuck calfskin with tone-on-tone topstitching; 18K white or yellow gold buckle

Price: CHF 148,000, excluding taxes

Availability: Limited production of 10 watches per year