Revolution Awards 2025: Material Innovation — TAG Heuer Carbon Hairspring

Editorial

Revolution Awards 2025: Material Innovation — TAG Heuer Carbon Hairspring

Material innovation in watchmaking over the past two decades has often been most visible in cases and other external parts of a watch, and less frequently at the level where performance is actually determined. The Material Innovation Prize exists to recognize those rarer moments when the development and mastery of new materials are directed toward delivering meaningful performance gains rather than cosmetic effect. In that context, TAG Heuer’s carbon hairspring is a landmark achievement which addresses a foundational component of the mechanical watch and does so with a clear aim of industrial production.

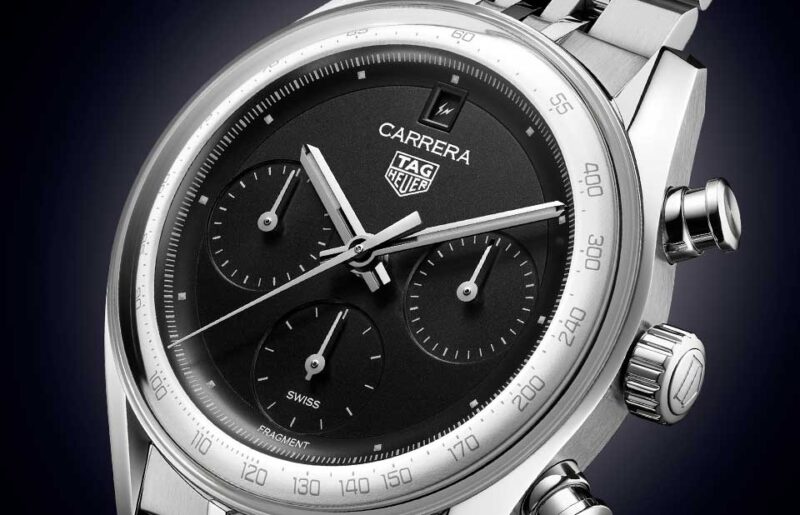

TAG Heuer marked the debut of its latest generation carbon hairspring with two limited edition chronographs — the Monaco Flyback Chronograph TH-Carbonspring and the Carrera Chronograph Tourbillon Extreme Sport TH-Carbonspring. The TH-Carbonspring represents the culmination of a decade of research aimed at developing a non-metallic hairspring that retains the advantages of silicon while overcoming its principal limitation — brittleness.

TAG Heuer Monaco Flyback Chronograph TH-Carbonspring and TAG Heuer Carrera Chronograph Tourbillon Extreme Sport TH-Carbonspring

Carbon hairsprings are not new to TAG Heuer. The brand first introduced carbon nanocomposite hairsprings in 2019, but their use remained intermittent and limited. The road to long-term stability and scalability proved longer. The current TH-Carbonspring marks the point at which those obstacles have been resolved. Protected by multiple patents, the technology now reflects a level of maturity consistent with serial production.

From a materials perspective, the advantages of carbon are clear. Like silicon, it is entirely non-magnetic, extremely lightweight, intrinsically stable across temperature variations and amenable to highly optimized, lithography-defined geometries. Unlike silicon, however, carbon is far less brittle and markedly more damage tolerant, making it significantly more resistant to shock and far less vulnerable during handling. These properties address the practical realities of modern watchmaking, where robustness is inseparable from theoretical performance.

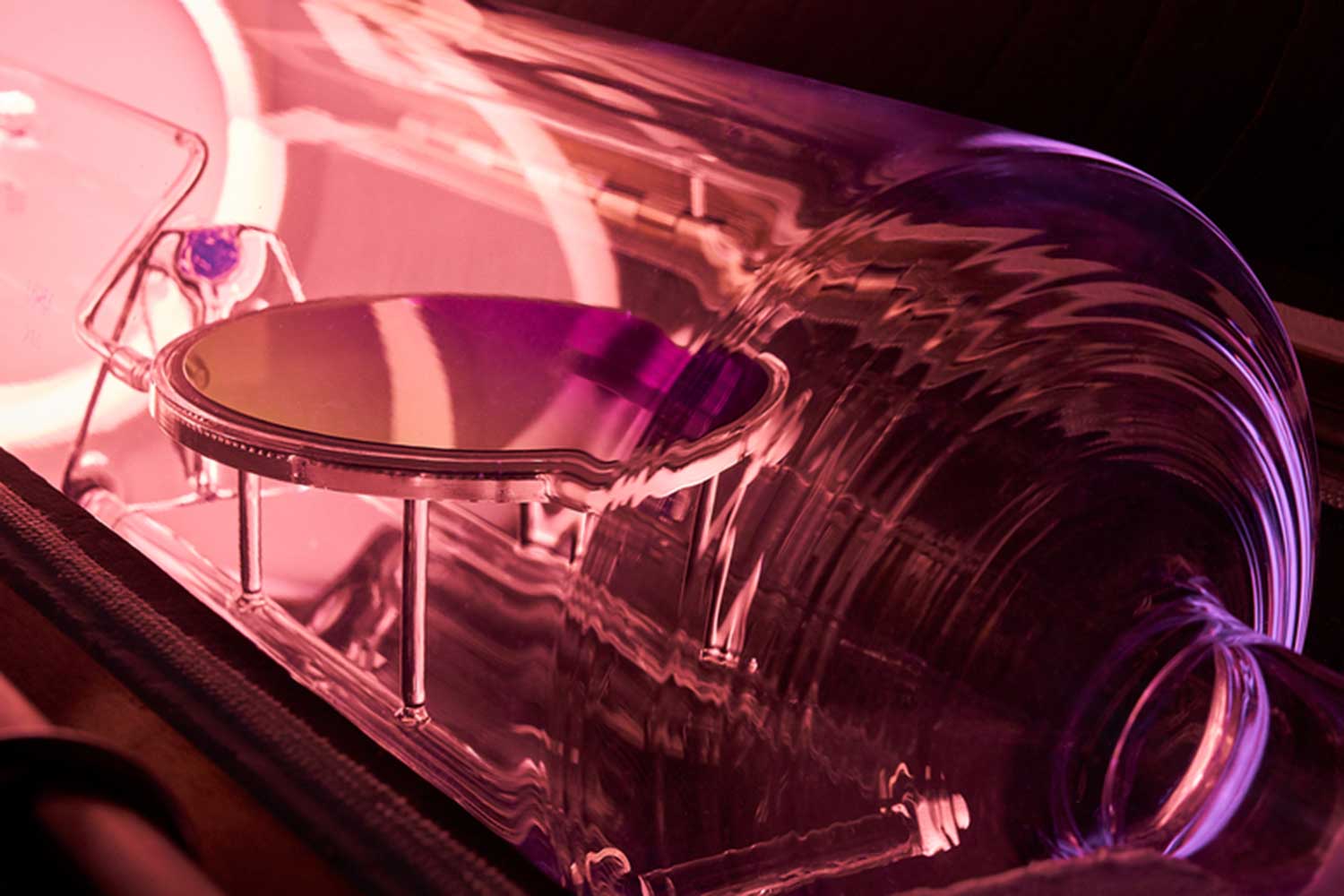

The breakthrough underpinning the TH-Carbonspring lies in stabilizing its behavior at both its structural and surface levels. At the material level, the spring is built around a forest of vertically grown carbon nanotubes infiltrated with pyrolytic carbon, a construction that delivers extreme geometric precision and a highly controlled, anisotropic elastic response. At scale, the open porosity and high surface energy inherent to nanostructured carbon promote the adsorption of ambient humidity and volatile constituents such as oil. This was addressed by combining a controlled CVD carbon overcoat that partially closes pore entrances with a covalent diazonium-based functionalization that grafts a fluorinated chain onto the carbon surface, forming a hydrophobic, low-energy monolayer.

The TH-Carbonspring’s creation begins with chemical vapor deposition (CVD) inside a high-temperature chamber, where hydrocarbon gases decompose at 600–850°C on a metallic catalyst layer

The two watches chosen to debut the TH-Carbonspring are rendered almost entirely in carbon composite, which alludes to the innovation within. This achievement signals TAG Heuer’s intent to compete at the highest level of fundamental watchmaking technology, and it points toward a future in which carbon may stand alongside, if not eventually supplant, silicon as a material of choice for high-performance oscillators.

TAG Heuer