Revolution Awards 2025: Chronometric Advancement — Grand Seiko Spring Drive U.F.A.

Editorial

Revolution Awards 2025: Chronometric Advancement — Grand Seiko Spring Drive U.F.A.

The Chronometric Advancement award is issued to recognize advances in chronometry that meaningfully extend or exhaust the state of the art. While the Grand Seiko Spring Drive U.F.A. (for Ultra Fine Accuracy) does not compete on the same axis as conventional fully mechanical movements or chronometric solutions, its achievement is unambiguously chronometric in nature. In effect, Spring Drive extended the state of the art and the U.F.A. exhausted the paradigm it created.

It improved Spring Drive’s usual precision of ±10 seconds per month by an order of magnitude, to ±20 seconds per year, becoming the most accurate mechanically powered wristwatch. The solutions are unique to Spring Drive, itself unique to Seiko and Grand Seiko, and without parallel anywhere else in watchmaking. To exclude it because it does not fit inherited categories is to protect definitions rather than recognize progress.

The invention and evolution of Spring Drive remains one of the most admirable undertakings in modern watchmaking. It was and still is pursued in isolation, inside a single company, driven for decades by one engineer’s conviction that a fundamentally different answer to timekeeping was possible. There was no parallel research track, no external validation, no market incentive to persevere. Quartz had already “won,” mechanical watchmaking was entering its post-crisis revival, and there was no commercial reason to invest in a system that belonged to neither camp.

Beyond that, Spring Drive is difficult to explain, expensive to develop and impossible to outsource. To make it viable, Seiko simply had to have its own capabilities such as growing its own quartz crystals, developing ultra-low-power ICs, designing electromagnetic regulators and training watchmakers to assemble and adjust a system that straddles mechanics and electronics. None of this could be amortized across an industry or licensed to others. It required building an entire infrastructure solely to support a single idea.

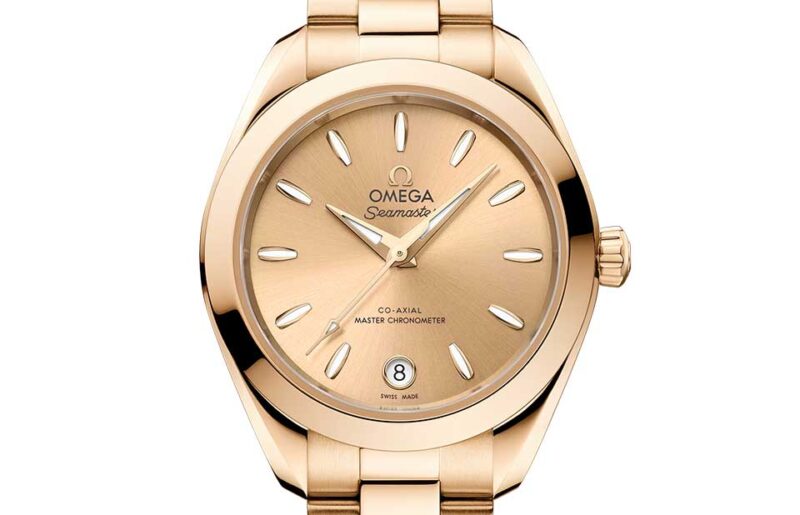

A ceramic-capped, vacuum-sealed quartz crystal integrated with its thermistor, control IC and wiring

As Spring Drive entered series production, advances in semiconductor efficiency, oscillator manufacturing, thermal compensation, mainspring technology and tooth geometry each played a role in turning Spring Drive from what seemed like a conceptual cul-de-sac to a full-fledged horological platform as capable of refinement, variation and adaptation as any mechanical movement across the wide spectrum of watchmaking.

The processing method of the quartz oscillator, the design of the IC within the package and the packaging process itself were refined while on the mechanical side, the gear teeth were optimised to improve transmission efficiency

The U.F.A. is the fullest expression of that long commitment and a hard won victory. Its achievement is not reducible to any single component or innovation, but lies in the relentless way the various elements have been pushed further toward a single objective — the suppression of long-term variation. It essentially closes every remaining path by which error can accumulate over time. That suppression begins at the level of the reference itself. Like preceding Spring Drive movements, the quartz crystal has been aged for three months to stabilize its frequency and then sealed, together with the thermistor, IC and wiring, in a vacuum package to shield the system from humidity, static and light. What has changed is how that oscillator is processed. Quartz, being crystalline, carries within it residual stress from the way it is cut, and over time that stress can express itself as minuscule shifts in oscillation frequency. In the Caliber 9RB2, new methods of relieving this stress have been introduced, reducing the tendency of the crystal to “relax” back to its original state.

The brain that governs the crystal has also been rethought. The integrated circuit is newly designed, still operating at ultra-low power but with its logic refined to suppress even the smallest variations in frequency. Every oscillator drifts slightly depending on temperature, and in Spring Drive, that drift is checked 540 times a day, with each reading used to apply thermo-compensation and keep the rate steady across the range of everyday wear. In the 9RB2, these corrections are applied with greater precision, ensuring that deviations are contained before they can accumulate. Additionally, for the first time, the Caliber 9RB2 incorporates a regulation switch, enabling fine adjustment during servicing to correct for long-term drift.

The mechanical side is treated with the same obsessive care. Where the 9RA2 relied on two serially coupled barrels for a 120-hour power reserve, the 9RB2 pares this back to a single barrel with a 72-hour power reserve. However, mainspring torque has been increased and the profile of the gear teeth was redesigned to improve transmission efficiency. Energy is now delivered with less loss across the train, and the glide wheel, responsible for converting energy into a seamless sweep, receives a steadier flow of torque.

The movement remains 30mm in diameter, the same as 9R65, but its magnetic shielding is divided into four discrete sections, arranged within the available clearances on either side of the movement, allowing it to be cased at 37mm for the first time.

It is an impressive accomplishment and one that is inherently beyond comparison with conventional chronometric categories and strategies, yet falls squarely within the purpose of this award.

Grand Seiko