Hublot: Milestones in Innovation

Editorial

Hublot: Milestones in Innovation

Hublot is not a name that lends itself to neutrality. It is well-loved by some for its audacity and dismissed by others for the same reason. Its reputation rests largely on spectacle — larger than life designs, unexpected combinations of materials and high wattage marketing. But behind the pyrotechnics is a story that has rarely been told on its own, that of a brand that has consistently pursued the future of mechanical, technical watchmaking.

Admittedly, I have written about Hublot only a handful of times in nearly a decade of covering watches, but each experience has revealed another side of a brand too often dismissed at first glance. The last was in 2023, with the Big Bang Unico in King Gold. It is a model so familiar that I thought I knew what I was looking at, but I didn’t. Visible right through the dial was a clutch wheel with sprung teeth glaring up at me like a school teacher catching a student daydreaming.

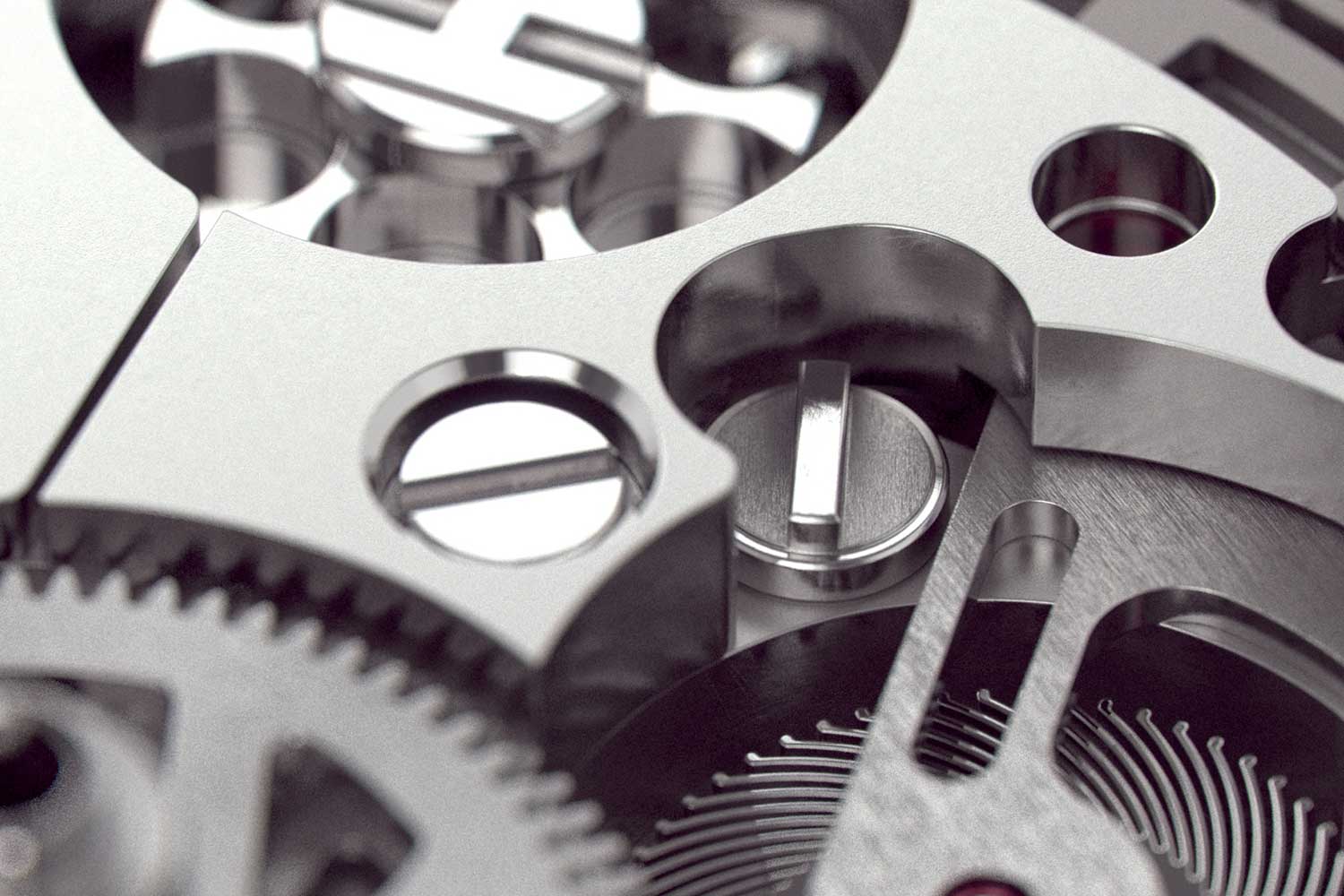

Suitably chastened, I looked up the patent and was intrigued to find that the clutch consists of an arbor with LIGA-fabricated wheels at both ends, each with elastic teeth of a different geometry. The one on the dial side, if you must know, features pennant-shaped elastic teeth which meshes with the chronograph seconds wheel, while the wheel on the movement side uses a split-tooth profile which engages with the driving seconds wheel. Both are designed to absorb play and deliver torque smoothly, eliminating the telltale jump when the chronograph starts.

It may sound like a small detail, but it’s anything but trivial. Designing functional tooth profiles is one of the most rarely mastered areas of watchmaking. Each curve must be calculated to balance stiffness, elasticity and contact pressure while maintaining constant angular velocity through engagement. Most brands simply use off-the-shelf gear geometries, but to develop and fabricate your own especially in LIGA requires a solid grasp of mathematics, kinematics and energy transfer. It is a mark of genuine, foundational engineering strength. It was an unexpected but welcome reminder that, behind the bombast, Hublot has done the work. What else have I missed?

This is an earnest attempt to find out. Consider it a long-overdue survey, an effort to see the brand not through the lens of marketing but through the mechanics that underpin it. Because if you look past the sapphire cases, rainbow-gem-encrusted watches and collaborative bravado, what you’ll find is a company that has spent the past two decades building out serious development and manufacturing capabilities and, in doing so, a legitimate mechanical identity all its own.

The Foundations

To understand how Hublot got here, it helps to look back at where it began. It was in 2004 when Jean-Claude Biver joined Hublot as CEO, long after the brand, founded by Italian entrepreneur Carlo Crocco in 1980, had faded into relative obscurity. In 2005, he launched the Big Bang, inspired by the cosmological event and built on the philosophy of creation through fusion. Following a fivefold increase in sales between 2004 and 2007, Hublot was acquired by LVMH in 2008. A year later, the brand inaugurated its manufacture in Nyon, with a second facility following in 2015. In between, in 2010, Hublot acquired BNB Concept, the complication specialist founded by Mathias Buttet, Michel Navas and Enrico Barbasini.

- Jean-Claude Biver

- Carlo Crocco

- Mathias Buttet

Before the collapse of BNB Concept was publicly announced, Hublot, its biggest client, had already moved decisively, purchasing the firm’s existing movements and spare parts. In 2010, Hublot went further, acquiring the company’s equipment leases and relocating the machinery to its own production site. Along with the physical assets came Mathias Buttet, BNB’s founder, and 29 watchmakers and specialists across a wide array of expertise ranging from chemistry and micromechanics to finishing. Effectively, Hublot had transplanted an entire research and development lab into its own ecosystem.

This influx of talent and capability laid the foundation for a bifurcated production structure at Hublot. On one side is the Unico division, focused on foundational, in-house chronograph movements and, on the other, the high-concept atelier, initially branded the Confrérie Horlogère Hublot, was tasked with producing tourbillons, minute repeaters and other complicated pieces.

The First In-House Movement: The Unico

The brand’s first in-house movement was the flyback Unico Caliber HUB1240, introduced in 2010. In time, it would evolve into the Caliber HUB1280, which became the subject of my recent epiphany.

The Unico Caliber HUB1240 was conceived as a replacement for the ubiquitous Valjoux 7750 that had powered Hublot chronographs until that point. It maintained similar dimensions, making it immediately compatible with existing cases. Though it borrowed the basic gear train of a 7750, the Unico was an ambitious exercise in reimagining a familiar workhorse. Under the direction of then-CEO Jean-Claude Biver, the movement was designed with an unusual objective: to relocate the chronograph works to the dial side, making the action of the mechanism visible to the wearer.

This decision naturally led to a modular construction, which is practical from a servicing standpoint and consistent with Hublot’s philosophy of industrial clarity by enabling components and complications to be interchanged or expanded in future evolutions. The most significant aspect of the movement is that it employed a double horizontal clutch system — one for the minutes recorder wheel, which was directly driven off the barrel, and one for the chronograph seconds driven off the fourth wheel.

The levers are controlled by a column wheel and a flyback function was added, which is something we take for granted today but is inherently difficult to implement. The movement also employed a compact bidirectional winding system using a variation of a Pellaton winding system. Its slim architecture was achieved by integrating the winding drive directly into the rotor. Instead of relying on two rollers mounted on extended arms to follow a cam, the system uses a single low-friction roller engaging a groove recessed within the rotor hub. This eliminated the need for bulky levers and reduced the overall height of the automatic winding module, while preserving the bidirectional efficiency. It also used a modular escapement, allowing it to be removed, adjusted or replaced without having to disassemble the rest of the movement. The escape wheel and pallet fork were made of silicon, which reduces inertia where it matters most.

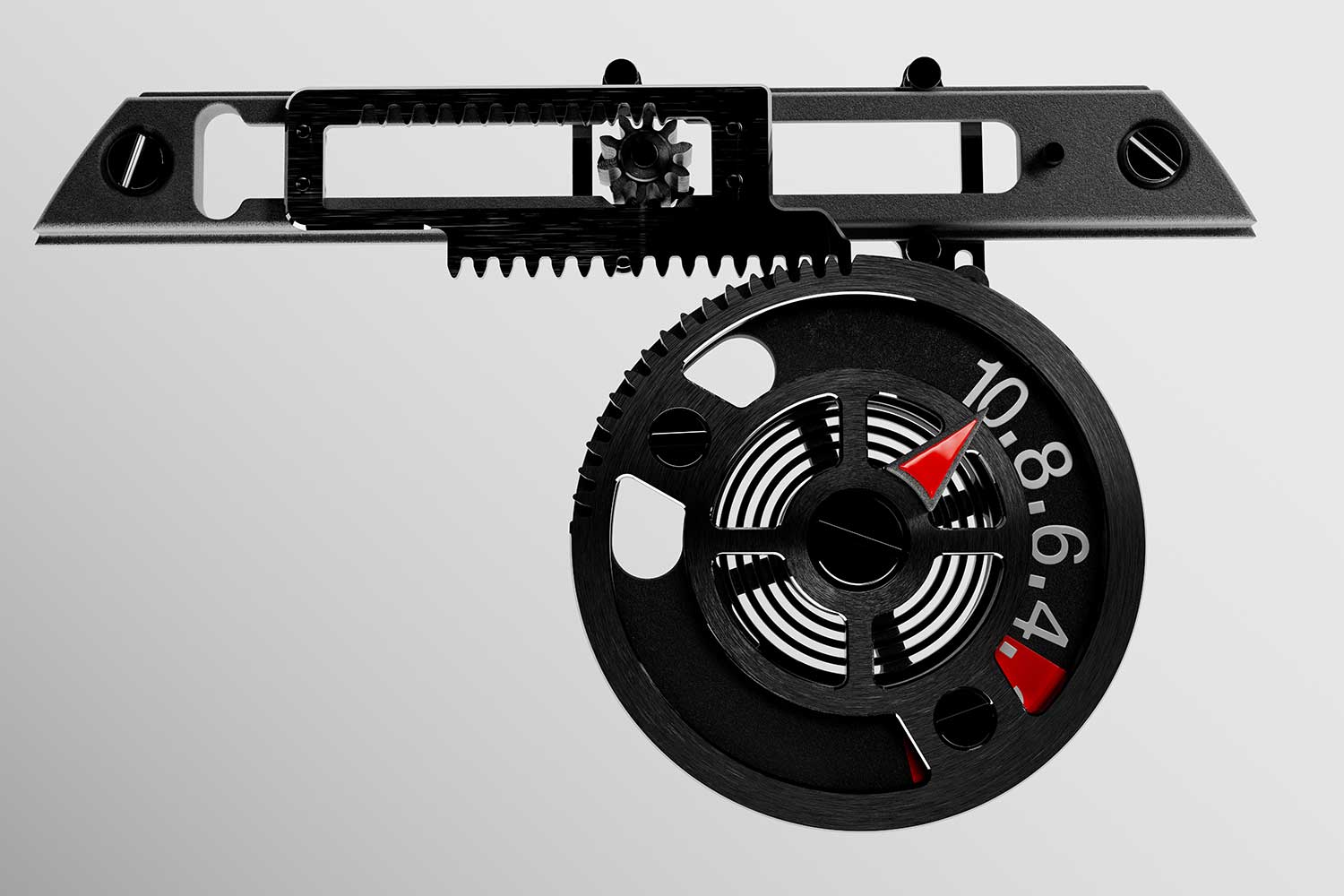

In 2018, the movement underwent a significant revamp and became the HUB1280. Its fundamental construction changed. Despite being on the dial side, the chronograph mechanism was no longer modular but fully integrated into the mainplate. This led to a significant reduction in thickness from 8.05mm to 6.75mm. Most notably, the new caliber adopted the principle of an oscillating pinion but the pinions were replaced with LIGA-fabricated nickel-phosphorous wheels with reactive, spring-loaded tooth profiles to address the issue of backlash and imperfect mating during coupling.

The upper clutch wheel, which engages and drives the chronograph seconds hand, features pennant-shaped elastic teeth with rounded ends. These teeth are curved and flexible, designed to slide smoothly into place between the triangular teeth of the chronograph wheel rather than striking the tips of the teeth during engagement.

In contrast, the lower clutch wheel, which remains permanently meshed with the driving seconds wheel, uses split teeth formed by two springy arms separated by a gap. Together, these flexible tooth designs absorb microscopic errors in concentricity, eliminate backlash and maintain tension in the gear train. As a result, as opposed to a traditional horizontal clutch chronograph, the chronograph starts instantly and fluidly, without the sudden lurch of a start jump. The intermediate pinion in the minute coupling drive train also features split teeth made up of two elastic blades to absorb play. The tooth profiles and the movements themselves were developed by Christophe Lyner, an engineer and movement designer who has been with Hublot since 2009. Lyner discusses the movement in more detail here.

Traditionally, in a chronograph, controlled friction is applied to certain wheels, particularly the coupling and chronograph seconds wheels, to ensure that the hands remain perfectly still when the chronograph is disengaged and move instantly and smoothly when it is started. This friction, usually imperceptible in strength, prevents flutter or drift of the chronograph hand when stopped and eliminates any hesitation when engaged. To achieve this, watchmakers have long relied on a thin, flexible spring leaf or shim, often made of steel or brass, that presses gently against the rim or hub of the chronograph wheel. The degree of friction depends entirely on the elasticity and positioning of this spring, both of which must be adjusted with extreme delicacy.

The problem is that this method is neither precise nor convenient, and even a slight change in the bend or position of the spring can have a disproportionate effect. Adjusting it usually requires the watchmaker to partially disassemble the movement, remove the spring, bend or replace it, and reassemble the mechanism to test the result. This process is laborious, imprecise and often has to be repeated several times to achieve the desired result. Moreover, once the watch is cased, there is no way to fine-tune the friction without reopening the movement, and the friction itself can vary over time as the spring tension changes or its contact surface oxidizes.

In the HUB1208, it is replaced by a compact, accessible system that uses a screw to apply and regulate axial pressure. Instead of pressing laterally on the wheel, the system acts along the pivot axis through a spring, an arbor and a ball interface that transmit force directly to the pivot shoulder of the chronograph wheel. Turning the screw compresses or relaxes the spring, increasing or decreasing the friction in a predictable, measurable way. Because the ball ensures that the force is applied strictly along the axis, there is no unwanted torque or binding. The adjustment can be made externally, from the bridge side, without dismantling the movement. In this way, a process that was once a matter of trial and error becomes precise, reversible and easily serviceable, giving the watchmaker direct control over one of the most delicate parameters in chronograph regulation.

Turning the screw compresses or relaxes the spring, this adjustment can be made externally without dismantling the movement

The foundation of the movement was also improved. Instead of using a click and spring to prevent the barrel from unwinding, it employs a pivoting rocker carrying a pair of gears with specially shaped teeth that form an irreversible train. When the watch is wound, the gear pair transmits torque smoothly to the barrel; when the mainspring tries to unwind, the tooth profiles lock, blocking reverse rotation. A thin integrated leaf spring returns the rocker to its rest position, maintaining engagement without additional parts. The design eliminates the familiar clicking noise of conventional systems, reduces friction losses during winding and improves energy transfer efficiency. Compact and simple, this mechanism allows the barrel to rotate freely in one direction while locking silently in the other, achieving the same one-way function as a click but with far greater refinement.

Additionally, the friction wheel that carries the cannon pinion improves upon the classic design – where two spring arms pinch the arbor – by adding reinforcing and linking arms, giving a stronger, more consistent and longer-lasting friction torque.

Finally, the regulator was also redesigned with a toothed circular sector integrated directly into the arm. Fine adjustment is made by turning a screw that drives a pinion engaging this toothed arc. At the root of the teeth lies a flexible structure that maintains constant contact between the meshing flanks, eliminating play. This ensures smooth and precise regulation in either direction, while also making the mechanism easier for watchmakers to access and adjust.

Cathedral Minute Repeater Tourbillon Chronograph and F1 Tourbillon Chronograph — 2011

In 2011, Hublot unveiled the Cathedral Minute Repeater Tourbillon Chronograph and the F1 Tourbillon Chronograph, both powered by movements that originated at BNB Concept.

While tourbillons and chronographs are relatively common as standalone complications, their combination remains uncommon due to a mix of architectural, spatial and energy constraints. A watch that integrates both must resolve several conflicting priorities. A visible tourbillon competes for dial space with chronograph registers, and at the gear train level, a tourbillon is driven by a fixed fourth wheel, whereas a chronograph typically draws power from the fourth wheel to measure elapsed seconds, creating an inherent conflict. Moreover, both complications are energy-intensive, demanding efficient transmission and strong torque.

Against this backdrop, the Tourbillon Chronograph designed by BNB Concept stands out for its unconventional architecture. It is a monopusher design that dispenses with a central chronograph seconds hand in favor of a sub-seconds register positioned between 1 and 3 o’clock, with the entire chronograph mechanism arranged on the dial side. This inversion likely stems from the fact that the foundation of the movement was conceived to accommodate a minute repeater gear train while allowing flexibility for derivative configurations — tourbillon with or without chronograph, and with or without repeater.

The chronograph features a horizontal clutch, but with a highly original configuration. When activated, the clutch wheel pivots toward the tourbillon cage, allowing the cage itself to drive the entire chronograph gear train. This eliminates the need to drive the chronograph from the fourth wheel; the gear train is conventional and the tourbillon cage is driven by the third wheel. This means that the chronograph mechanism is directly coupled to the regulating organ upon activation. It’s a daring construction that demands extremely precise torque management especially since the tourbillon cage, which represents an additional load, must now deliver consistent power not only for timekeeping but also to drive the load of the chronograph mechanism. That such a system operates reliably is a testament to the team’s engineering prowess.

2025: Celebrating Big Bang 20th Anniversary, Hublot presents the Big Bang Tourbillon Chronograph Cathedral Minute Repeater in black frosted carbon fiber and Blue Texalium

In the minute repeater variant, the strike works, along with the strike train, is located on the mainplate below the chronograph plate, while the hammers, repeater barrel and governor are visible on the bridge side. Cathedral repeaters are distinguished by their extended gongs, which are coiled twice around the movement to produce a deeper, more resonant sound, akin to the rich acoustics of a cathedral. In 2014, Hublot introduced the Classic Fusion Cathedral Tourbillon Minute Repeater, which is based on the same movement but without a chronograph.

Indeed, the same tourbillon chronograph movement was taken forward by Rexhep Rexhepi in the AK-01 as he had formerly worked on the movement at BNB Concept. Meanwhile, Manufacture Hautes Complications (MHC), founded by fellow BNB alumnus Pierre Favre, continues to use a minute repeater tourbillon variant. Through MHC, derivatives of the movement can be found in a wide range of watches, from Hermès, Louis Vuitton and Ralph Lauren to H. Moser & Cie.

MP-02 Key of Time — 2011

The Masterpiece, or MP, collection represents the pinnacle of Hublot’s technical experimentation. It is where the company’s most audacious watchmaking ideas take form.

The series was launched in 2011 at a time when the brand, armed with newly in-house prowess, began to push the boundaries of haute horlogerie. The MP collection served as a platform for the most unusual complications and unconventional constructions that fell outside the aesthetic and technical language of the Big Bang and Classic Fusion lines.

One of the most radical creations of the series was the MP-02 Key of Time, conceived by Mathias Buttet. It was as much a philosophical exercise as a mechanical one. Its premise was simple yet subversive — to give the wearer the ability to make time appear to move faster or slower at will. With a three-position crown, the movement could be set to run at one-quarter speed, normal speed, or four times faster. The effect was purely visual. The gear train remains uninterrupted, and the watch continues to keep time but the display was altered through a system of differentials that changed the transmission ratio between the gear train and the hands.

In its slowest setting, an hour in real life would pass as just 15 minutes on the dial. In its fastest, the hands would whirl through four hours in the same span. Yet the watch kept track of true time internally, and the moment the crown was returned to its neutral position, the hands would automatically re-synchronize, catching up or falling back to the correct display. It was, in essence, a mechanical simulation of perception — a watch that acknowledged that time does not always feel the same to everyone.

Technically, it was a formidable piece of engineering, built around a vertical flying tourbillon and a 120-hour power reserve. Aesthetically, it looked like something out of science fiction with its angular titanium case and multi-layered dial. But more than anything, the MP-02 Key of Time embodied that the MP collection was meant to be a playground for ideas that challenge what a watch could be and what it could do.

MP-08 Antikythera — 2012/2013

In 2011, Hublot undertook one of the most ambitious projects in modern watchmaking, which was to translate the wonder of the ancient Antikythera mechanism into a wristwatch. The original Antikythera mechanism, dated between 150 and 100 B.C., is a Greek astronomical device of astonishing sophistication that was recovered from a shipwreck off the island of Antikythera. Despite its corroded and fragmented state, modern imaging techniques have revealed that it was more than just a simple calendar. Among its many functions, the mechanism tracked the Metonic cycle — a 19-year period after which the phases of the Moon recur on the same days of the solar year, used by the ancient Greeks to reconcile lunar and solar calendars. This was displayed on a spiral dial on the back of the device, advancing one position for each lunar month and completing a full cycle over 235 lunar months. Nested within this were longer cycles, such as the 76-year Callippic cycle, and the 223-month Saros cycle used to predict eclipses. The Antikythera mechanism could also show the position of the Sun and Moon in the zodiac, model the varying speed of the Moon due to its elliptical orbit, and replicate the retrograde motion of the five known planets using complex epicyclic gearing. These planetary motions were displayed via a system of concentric, nested tubes and rings, centered on Earth, in accordance with ancient Greek geocentric cosmology.

Hublot’s endeavor led to the creation of four non-commercial movements known as the Tribute to the Antikythera Mechanism. Led by Mathias Buttet, the project sought to translate the mechanism into a fully functional movement scaled to the dimensions of a wristwatch. In other words, it was a re-imagining of a 2nd century B.C. astronomical computer through the lens of 21st-century haute horlogerie.

At its core, the Tribute to the Antikythera Mechanism was built around a conventional timekeeping organ — a one-minute tourbillon — which regulated a vast array of astronomical indications derived from the original device. On the front, the dial displayed a wealth of information: the Egyptian 365-day calendar with its epagomenal days, the Panhellenic games calendar including the Olympic Games, the position of the Sun within the zodiac, and the age and phase of the Moon. A large aperture traced the Moon’s progress through the constellations, accounting for the slight variations in its orbit through a differential system inspired by the ancient model.

Turning the watch over revealed an even more remarkable sight: the great spiral dials of the ancient mechanism, showing the Metonic, Callippic, Saros and Exeligmos cycles — respectively spanning 19, 76, 18 and 54 years. Each was driven by intricate trains of reduction wheels that advanced imperceptibly with each lunar month.

The upper-left spiral traced the Metonic cycle, a 19-year period corresponding to 235 lunar months. The lower-right spiral represented the Saros cycle, covering 223 lunar months, or roughly 18 years, the interval after which lunar and solar eclipses repeat. In both, the indications were read by a telescopic hand whose tip advanced outward as it rotated, guided by a cam that modulated its length so it could follow the spiral track precisely. This ingenious mechanism allowed each long astronomical cycle to unfold seamlessly across several revolutions of the dial, recreating the ancient cosmos within the dimensions of a wristwatch. The Callippic and Exeligmos cycles, which are four and three times longer than the Metonic and Saros respectively, were displayed on smaller subdials.

In mechanical terms, the movement was not an astronomical watch in the modern sense but a cosmograph, a machine for describing the cosmos. Its purpose was not to tell the time of day but to demonstrate, in miniature, how the ancient Greeks encoded celestial mathematics into bronze gears. At the time, the existence and configuration of a planetary display within the original device remained speculative. Accordingly, Hublot’s wristwatch adaptation, launched years before any definitive reconstruction, focused solely on solar and lunar functions. It wasn’t until 2021 that the University College London (UCL) Antikythera Research Team published a landmark study proposing a complete model of the Antikythera mechanism and offered strong evidence that it functioned as a full mechanical planetarium capable of representing all five planets known in antiquity.

In 2013, Hublot introduced the Antikythera SunMoon, a commercially simplified version of its museum-grade tribute to the ancient Greek mechanism. Presented at Baselworld that year, the watch distilled the project’s immense complexity into a more wearable form while preserving its intellectual and aesthetic spirit.

Where the Tribute movement had nearly 495 parts and 13 indications, the SunMoon pared this down to 295 components and seven indications, focusing solely on the celestial relationship between the Sun, the Moon and the constellations. All its indications were placed on the dial side, making it a direct, highly visual expression of the heavens in motion. It allows the wearer to determine the phase and age of the Moon, the constellation behind it, and the time it takes to cross that constellation. At the same time, it reveals the constellation lying behind the Sun and the time required for the Sun to pass through it. Beneath this astronomical display, a flying tourbillon at 6 o’clock completes one rotation every minute, indicating the seconds, while conventional central hands mark the hours and minutes.

Beyond the watch, Hublot has been a significant supporter of the “Return to Antikythera” project, a modern archaeological initiative aimed at re-examining the ancient shipwreck using advanced technologies. It’s an exceptionally rare example of a watch brand engaging with an academic effort so deeply rooted in history, science and cultural heritage, far removed from typical marketing partnerships. The project was led by the Hellenic Ministry of Culture and Sports, in collaboration with the Woods Hole Oceanographic Institution (WHOI) and other international partners. Hublot’s contributions include funding and technological assistance, such as the development of precise 3D digital models of artifacts, enhancing both the excavation process and the sharing of discoveries with the public.

Notably, Hublot’s involvement extended to the deployment of advanced diving equipment and imaging systems during the expeditions. These technologies have been instrumental in uncovering significant artifacts, including marble statues, ceramic fragments and a substantial section of the ship’s wooden hull during the 2024 expedition.

MP-05 LaFerrari — 2013

In 2013, Hublot unveiled the MP-05 LaFerrari which provided a 50-day power reserve with the use of 11 barrels. It was the end-all of a whole genre of competition among watchmakers for the longest power reserve and a reimagining of what horology can look like when freed from the constraints of convention and shaped by the design language of hypercars. Created in collaboration with Ferrari, the MP-05 LaFerrari channels the spirit of a V12 engine directly into its movement architecture.

The MP-05 LaFerrari with stack of mainspring barrels aligned vertically along the central axis of the watch (©Revolution)

At the heart of the MP-05 is a stack of mainspring barrels aligned vertically along the central axis of the watch. These barrels are mounted in series and the result is a staggering 50-day power reserve. Till today, it holds the record for the longest power reserve of any wristwatch.

Visually, the stacked barrels resemble pistons in an engine block. When the watch is wound, the ratchet wheel winds the first barrel directly through its arbor and, as its spring tightens, its drum drives an intermediate wheel which in turn winds the next barrel and the chain continues in this fashion until the final one in the sequence is fully wound. Each barrel has its own arbor, though some are shared between adjacent barrels, forming a linked sequence rather than one continuous shaft through the entire stack. Because the barrels are stacked co-axially, the entire column must stay perfectly aligned while allowing each drum to turn freely. To minimize friction and maintain alignment, a line of roller jewels are mounted alongside the barrel drums. While the full system of 11 barrels can theoretically sustain the movement up to 55 days, it is intentionally stopped around the 50-day mark. Halting the movement before the final low-torque phase ensures that the entire usable reserve delivers consistent energy.

This configuration preserves the linear, engine-like architecture of the movement while aligning the regulating organ with the natural resting position of the watch, which is flat. In this orientation, the cage remains perpendicular to the ground, and the vertical tourbillon compensates by rotating through that gravitational plane, averaging rate variations within it.

Time itself is displayed via rotating drums or cylinders. On the right hand side of the movement, there are two vertically stacked rollers: the upper one indicates the hour, and the lower one shows the minutes. These rollers are milled from aluminum and finished in a vivid yellow lacquer to ensure legibility against the open movement. The same construction is echoed on the left-hand side, where another drum indicates the remaining power reserve.

Winding the MP-05 presents its own challenges. With such a massive power reserve, manual winding via a traditional crown would be impractical. To address this, Hublot developed a custom electric tool, resembling a miniature drill, that engages directly with the winding stem to wind all 11 barrels in a controlled and uniform manner. This tool ensures consistent performance and in a way, reinforces the industrial, machine-like identity of the watch. A large, curved sapphire crystal across the front offers a panoramic view of the engine-inspired movement, and a later version carried the idea further with a case entirely fashioned from sapphire for maximum visual impact.

Big Bang MECA-10 — 2016 (45mm) and 2025 (42mm)

The original Big Bang MECA-10 arrived in 2016, initially in black ceramic and titanium cases. Though it’s a time-only movement with a power reserve display, its construction is visually complex. It was inspired by Meccano, the early 20th-century construction system invented in England by Frank Hornby. It consists of metal strips, plates, gears, pulleys, nuts and bolts, which can be assembled to build mechanical models like cranes, bridges and vehicles.

Everything about the MECA-10 insists that mechanics are less a means to an end but the point itself. It is one of Hublot’s most compelling movements for the way it openly and exuberantly lays bare the act of doing. The Caliber HUB1201 is entirely open-worked. There is no mainplate. It is made up of a peripheral ring to which flat bridges that support the components are attached. It is equipped with two partially open-worked barrels mounted in parallel. Despite the parallel configuration, which prioritizes torque over duration, the movement achieves a 10-day power reserve, made possible by its substantial dimensions; at 35.2mm wide, there is ample space to accommodate unusually large barrels. At the same time, it has a slightly lower beat rate of 21,600vph, meant to extract the most power reserve. On the reverse, there are three lateral bridges that resemble the flat, perforated metal strips used in Meccano sets.

At the heart of the movement is a remarkably elaborate system for the power reserve indicator. In fact the power reserve mechanism comprises over 30 parts. The differential gearing is visible between 10 and 12 o’clock on the dial. During winding, the ratchet wheel drives an intermediate pinion which drives the input wheel in the differential. As the watch runs, the barrel drives the second input wheel in the differential. The differential consist of a planet gear that is mounted on a carrier, which is connected to both input wheels. As both input wheels rotate, the planet gear is driven to turn due to its engagement with the internal teeth of the ring gear. Because the planet gear is fixed to the carrier, this interaction causes the entire carrier to rotate around its central axis. That central rotation is transmitted upward through the carrier’s shaft to the output pinion. The output pinion of the differential then drives a set of intermediate gears, and the pinion on the last gear drives a dual rack system. Because the pinion is engaged with both the internal teeth on upper rack and lower rack, its rotation causes the two racks to slide in opposite directions. The upper rack, in turn, drives a wheel with radial slots and teeth over a short arc. A lower wheel with a red lacquered marker is pinned to the lower rack. As such, as the racks move, they drive their respective wheels in opposite directions. A red marker is gradually revealed during the last two days of power reserve. There’s a spring attached to the upper wheel that provides a constant bias to keep the system under load. This is necessary as the racks are driven by a differential, which outputs only a net angular position depending on the balance of winding and running, not active power. The spring thus ensures the upper wheel is fully engaged with the rack and pinion system, eliminating free play. The upper wheel then drives an indicator window, while the lower wheel drives a silver disk with numerals from 0 to 10. Together, they indicate the remaining number of days of power reserve.

The original MECA-10 debuted in a 45mm case, but this year Hublot has introduced a more compact 42mm version. To fit the smaller case, the new Caliber HUB1205 had to be reduced in size as well from 35.2mm to 33.4mm. This downsizing required several modifications. Most notably, the secondary power reserve display at 6 o’clock has been omitted due to space limitations. As a result, the display at 3 o’clock now combines a red warning indicator that appears when only two days of power remain, with a co-axial hand that indicates the exact number of days left in the power reserve. Another update is the addition of a hacking seconds function. Pulling the crown now stops the balance wheel, allowing the time to be set precisely to the second.

Additionally, the HUB1205 introduces a revised regulator that is both functionally and visually improved. In the previous HUB1201, the regulator takes the form of a traditional index system. The regulator arm is adjusted via a lateral screw, which causes the arm to pivot slightly, shifting the position of the curb pins relative to the hairspring. In the HUB1205, this is replaced by a toothed circular sector integrated into the regulator arm. Fine adjustment is achieved by turning a screw that engages this toothed arc, which acts on a flexible structure located at the root of the teeth. This flexure maintains constant pressure between the meshing teeth, eliminating backlash and ensuring precise, repeatable adjustments in both directions. The result is a smoother, more controlled regulation system that’s also more accessible to the watchmaker.

MP-09 Tourbillon Bi-Axis — 2017

Introduced in 2017, the MP-09 Tourbillon Bi-Axis was, even by Hublot’s standards, an audacious piece of watchmaking. The Caliber HUB9009.H1.RA is a manually wound movement with five days of power reserve from a single barrel. The double-axis tourbillon turns once per minute on its inner axis and every 30 seconds on its outer, with the two axes set at 90 degrees to each other so that the escapement constantly shifts orientation in three-dimensional space. The entire lower half of the case exists to accommodate it; the sapphire crystal bends forward in a dramatic outcrop so the tourbillon can project beyond the plane of the dial.

The hypnotic rotation naturally draws the eye but the dual scale instantaneous date display, arcing around the offset dial, adds a nice touch as it makes for a larger, more sculptural display in limited dial space. It doesn’t use a standard date disk. Instead, its display is laid out on two concentric semi-circular scales — one carrying the numerals 1 through 15 on the inner ring, the other 16 through 31 on the outer. Two small indicators sit opposite each other on a 62-tooth wheel that advances one step every 24 hours.

As it advances, each indicator traces a half-circle over the course of a month, so one indicator completes its semi arc just as the other begins. The date finger is driven by a snail cam. Its rising profile gradually loads a spring, and as it reaches the crest of the cam, the spring releases its tension, advancing the date wheel forward by one increment precisely at midnight. Because every tooth corresponds directly to a date, the display can be adjusted forwards or backwards via a quick-set lever on the left side of the case.

MP-10 Tourbillon Weight Energy System — 2024

One of the most unusual and exciting developments in the Masterpiece line arrived just last year with MP-10 Tourbillon Weight Energy System. It combines an inclined tourbillon with a novel linear self-winding mechanism that dispenses entirely with the conventional oscillating rotor.

Instead of a semi-circular weight pivoted at the center of the movement, the MP-10 features two parallel sliding masses that move back and forth along guide rails in a straight line. These masses have jeweled openings that are mounted on dual arbors to ensure smooth, low-friction travel, and each carries a rack that engages a train of pinions and wheels connected to the barrel. Remarkably, the system is designed to wind the barrel in both directions. Both forward and return strokes wind the barrel so no movement of the weight is wasted.

The mechanism incorporates an ingenious damping device to absorb impact and eliminate noise. When a weight reaches the limit of its stroke, a lever positioned near the stop is pushed by the approaching mass. This lever pivots about a transverse axis and compresses a helical spring mounted co-axially with one of the guide arbors. The spring resists the motion of the lever and decelerates the mass before it touches the stop, then releases the stored energy to reverse its direction. The entire damping assembly, including the spring and lever, is cleverly packaged within the body of the moving mass itself, keeping the architecture compact and silent.

Beyond its mechanical ingenuity, the linear winding system offers an architectural advantage. It can be integrated into non-orthogonal movement layouts where a traditional rotor would be obstructive. In the MP-10, this freedom is used to full effect. The twin linear weights flank the hours and minutes displayed on aluminum rollers, alongside a circular power reserve indicator, while the tourbillon and seconds display are set on an incline.

The tourbillon carriage is mounted at a 35-degree angle to the mainplate. The cage itself is frustoconical, open on its outer side and cantilevered from the movement frame so that it appears to project outward, almost floating above the lower edge of the case. The balance and escapement are nested inside this conical structure, which rotates once per minute, doubling as a seconds display. There is a seconds scale printed on the conical surface, while a fixed index on the frame points to the running seconds as the cage turns.

Mechanically, the tourbillon is driven by a bevel-gear connection linking the horizontal gear train to the inclined carriage. The wheel of the intermediate train meshes with a bevel pinion co-axial with the tourbillon shaft. The balance wheel thus oscillates about an inclined axis, reducing the systematic rate errors associated with purely horizontal or vertical orientations while visually reinforcing the sculptural architecture of the MP-10. It is simply one of the most striking demonstrations of what the MP line set out to accomplish.

MP-11 14 Days Power Reserve — 2018

The MP-11 launched in 2018 takes the same engine-block concept of the earlier MP-05 and MP-07 watches and distilled it into a purer, more wearable form. The 45mm by 14.5mm case, though hardly discreet, is proportioned enough to make the watch plausible on the wrist rather than purely a statement. The appeal lies in how the long, linear bank of mainspring barrels reside within a round movement, which moreover can be wound via a large, fluted crown without external tools.

Where the MP-05 broke the case to accommodate its mechanics, the MP-11 folds the mechanics back into the case. The seven barrels form a straight horizon at the bottom of the dial, ending with a roller-based power reserve indicator while the gear train, balance wheel and time display occupy the upper half of the dial. The transition from the vertical to the horizontal plane is made possible by the helical toothing on the final barrel drum, which mesh with an intermediate wheel in the gear train cut with complementary slanted teeth.

The front crystal bulges outward along the lower half of the dial, tracing the curvature of the barrel train beneath. It’s interesting but as soon as the concept conforms to the visual grammar of a traditional watch, it is immediately more striking. The array of barrels appears even more dramatic, more improbable because it exists within a familiar order rather than defy it.

As time passes, and you begin to see how watches in the vein of Hublot tend to fade in leaner times or when classicism becomes the prevailing virtue, it becomes more obvious that producing such watches is a far more precarious undertaking than creating fine time-only dress watches. Technical development and material innovation demand enormous investment, and the rewards are uncertain. Every new material, manufacturing method and new mechanical idea represents a gamble on taste and timing. To build such watches is to insist that watchmaking is still capable of taking risks, that it can be experimental, expressive and alive to its era even when the safer path has never been more rewarding.

In the end, what I’ve come to see is that Hublot’s language of mechanics is inseparable from its aesthetics and its philosophy — the Art of Fusion — to bridge worlds, be it in marketing, materials or in creating watches that speak to a new generation. For all its extroversion, the brand continues to bet on ideas few others would dare attempt and that, in itself, is something few can claim. They may never look right to everyone and perhaps they never will. But watchmaking would be poorer without those willing to not only take risks but also to make them their stock in trade.

Hublot