The astounding movement now makes its way to the dial.

Bernhard Lederer first unveiled the Central Impulse Chronometer in 2021, and among certain enthusiast segments, its influence continues to reverberate whenever escapements or sophisticated modern chronometers are brought up. The reason being that he improved upon the independent double wheel escapement invented by George Daniels in the 1970s, which realized the merits of Breguet’s natural escapement without its shortcomings.

The natural escapement is one of the most fascinating escapements of all time as when considered in isolation, it is theoretically the most efficient escapement ever invented especially for pocket and wristwatches. Unlike anything else past and present, it uniquely delivers two impulses directly to the balance in opposite directions at each cycle.

In addition to greater transmission efficiency, its efficiency does not deteriorate over time. Beyond building on the work of Breguet and Daniels, Bernhard Lederer incorporated a pair of remontoirs to not only prevent power fluctuations but also maintain parity in the energy delivered to both escape wheels throughout the functioning of the watch.

Bernhard Lederer

Today he has unveiled the Central Impulse Chronometer InVerto, which inverts the movement to display its dual train architecture on the dial. The watch is an iteration of the pièce unique originally created for Only Watch 2023.

The decision to reveal the inner workings came after multiple requests by collectors to exhibit the bridge side of the movement on the dial. Limited to just 18 pieces, it is scheduled for delivery in the first quarter of 2024.

[vc_column_inner width=”1/6″][vc_column_inner width=”2/3″][vc_raw_html]JTNDYmxvY2txdW90ZSUyMGNsYXNzJTNEJTIyaW5zdGFncmFtLW1lZGlhJTIyJTIwZGF0YS1pbnN0Z3JtLWNhcHRpb25lZCUyMGRhdGEtaW5zdGdybS1wZXJtYWxpbmslM0QlMjJodHRwcyUzQSUyRiUyRnd3dy5pbnN0YWdyYW0uY29tJTJGcmVlbCUyRkMwaFpjcTRydWZZJTJGJTNGdXRtX3NvdXJjZSUzRGlnX2VtYmVkJTI2YW1wJTNCdXRtX2NhbXBhaWduJTNEbG9hZGluZyUyMiUyMGRhdGEtaW5zdGdybS12ZXJzaW9uJTNEJTIyMTQlMjIlMjBzdHlsZSUzRCUyMiUyMGJhY2tncm91bmQlM0ElMjNGRkYlM0IlMjBib3JkZXIlM0EwJTNCJTIwYm9yZGVyLXJhZGl1cyUzQTNweCUzQiUyMGJveC1zaGFkb3clM0EwJTIwMCUyMDFweCUyMDAlMjByZ2JhJTI4MCUyQzAlMkMwJTJDMC41JTI5JTJDMCUyMDFweCUyMDEwcHglMjAwJTIwcmdiYSUyODAlMkMwJTJDMCUyQzAuMTUlMjklM0IlMjBtYXJnaW4lM0ElMjAxcHglM0IlMjBtYXgtd2lkdGglM0E1NDBweCUzQiUyMG1pbi13aWR0aCUzQTMyNnB4JTNCJTIwcGFkZGluZyUzQTAlM0IlMjB3aWR0aCUzQTk5LjM3NSUyNSUzQiUyMHdpZHRoJTNBLXdlYmtpdC1jYWxjJTI4MTAwJTI1JTIwLSUyMDJweCUyOSUzQiUyMHdpZHRoJTNBY2FsYyUyODEwMCUyNSUyMC0lMjAycHglMjklM0IlMjIlM0UlM0NkaXYlMjBzdHlsZSUzRCUyMnBhZGRpbmclM0ExNnB4JTNCJTIyJTNFJTIwJTNDYSUyMGhyZWYlM0QlMjJodHRwcyUzQSUyRiUyRnd3dy5pbnN0YWdyYW0uY29tJTJGcmVlbCUyRkMwaFpjcTRydWZZJTJGJTNGdXRtX3NvdXJjZSUzRGlnX2VtYmVkJTI2YW1wJTNCdXRtX2NhbXBhaWduJTNEbG9hZGluZyUyMiUyMHN0eWxlJTNEJTIyJTIwYmFja2dyb3VuZCUzQSUyM0ZGRkZGRiUzQiUyMGxpbmUtaGVpZ2h0JTNBMCUzQiUyMHBhZGRpbmclM0EwJTIwMCUzQiUyMHRleHQtYWxpZ24lM0FjZW50ZXIlM0IlMjB0ZXh0LWRlY29yYXRpb24lM0Fub25lJTNCJTIwd2lkdGglM0ExMDAlMjUlM0IlMjIlMjB0YXJnZXQlM0QlMjJfYmxhbmslMjIlM0UlMjAlM0NkaXYlMjBzdHlsZSUzRCUyMiUyMGRpc3BsYXklM0ElMjBmbGV4JTNCJTIwZmxleC1kaXJlY3Rpb24lM0ElMjByb3clM0IlMjBhbGlnbi1pdGVtcyUzQSUyMGNlbnRlciUzQiUyMiUzRSUyMCUzQ2RpdiUyMHN0eWxlJTNEJTIyYmFja2dyb3VuZC1jb2xvciUzQSUyMCUyM0Y0RjRGNCUzQiUyMGJvcmRlci1yYWRpdXMlM0ElMjA1MCUyNSUzQiUyMGZsZXgtZ3JvdyUzQSUyMDAlM0IlMjBoZWlnaHQlM0ElMjA0MHB4JTNCJTIwbWFyZ2luLXJpZ2h0JTNBJTIwMTRweCUzQiUyMHdpZHRoJTNBJTIwNDBweCUzQiUyMiUzRSUzQyUyRmRpdiUzRSUyMCUzQ2RpdiUyMHN0eWxlJTNEJTIyZGlzcGxheSUzQSUyMGZsZXglM0IlMjBmbGV4LWRpcmVjdGlvbiUzQSUyMGNvbHVtbiUzQiUyMGZsZXgtZ3JvdyUzQSUyMDElM0IlMjBqdXN0aWZ5LWNvbnRlbnQlM0ElMjBjZW50ZXIlM0IlMjIlM0UlMjAlM0NkaXYlMjBzdHlsZSUzRCUyMiUyMGJhY2tncm91bmQtY29sb3IlM0ElMjAlMjNGNEY0RjQlM0IlMjBib3JkZXItcmFkaXVzJTNBJTIwNHB4JTNCJTIwZmxleC1ncm93JTNBJTIwMCUzQiUyMGhlaWdodCUzQSUyMDE0cHglM0IlMjBtYXJnaW4tYm90dG9tJTNBJTIwNnB4JTNCJTIwd2lkdGglM0ElMjAxMDBweCUzQiUyMiUzRSUzQyUyRmRpdiUzRSUyMCUzQ2RpdiUyMHN0eWxlJTNEJTIyJTIwYmFja2dyb3VuZC1jb2xvciUzQSUyMCUyM0Y0RjRGNCUzQiUyMGJvcmRlci1yYWRpdXMlM0ElMjA0cHglM0IlMjBmbGV4LWdyb3clM0ElMjAwJTNCJTIwaGVpZ2h0JTNBJTIwMTRweCUzQiUyMHdpZHRoJTNBJTIwNjBweCUzQiUyMiUzRSUzQyUyRmRpdiUzRSUzQyUyRmRpdiUzRSUzQyUyRmRpdiUzRSUzQ2RpdiUyMHN0eWxlJTNEJTIycGFkZGluZyUzQSUyMDE5JTI1JTIwMCUzQiUyMiUzRSUzQyUyRmRpdiUzRSUyMCUzQ2RpdiUyMHN0eWxlJTNEJTIyZGlzcGxheSUzQWJsb2NrJTNCJTIwaGVpZ2h0JTNBNTBweCUzQiUyMG1hcmdpbiUzQTAlMjBhdXRvJTIwMTJweCUzQiUyMHdpZHRoJTNBNTBweCUzQiUyMiUzRSUzQ3N2ZyUyMHdpZHRoJTNEJTIyNTBweCUyMiUyMGhlaWdodCUzRCUyMjUwcHglMjIlMjB2aWV3Qm94JTNEJTIyMCUyMDAlMjA2MCUyMDYwJTIyJTIwdmVyc2lvbiUzRCUyMjEuMSUyMiUyMHhtbG5zJTNEJTIyaHR0cHMlM0ElMkYlMkZ3d3cudzMub3JnJTJGMjAwMCUyRnN2ZyUyMiUyMHhtbG5zJTNBeGxpbmslM0QlMjJodHRwcyUzQSUyRiUyRnd3dy53My5vcmclMkYxOTk5JTJGeGxpbmslMjIlM0UlM0NnJTIwc3Ryb2tlJTNEJTIybm9uZSUyMiUyMHN0cm9rZS13aWR0aCUzRCUyMjElMjIlMjBmaWxsJTNEJTIybm9uZSUyMiUyMGZpbGwtcnVsZSUzRCUyMmV2ZW5vZGQlMjIlM0UlM0NnJTIwdHJhbnNmb3JtJTNEJTIydHJhbnNsYXRlJTI4LTUxMS4wMDAwMDAlMkMlMjAtMjAuMDAwMDAwJTI5JTIyJTIwZmlsbCUzRCUyMiUyMzAwMDAwMCUyMiUzRSUzQ2clM0UlM0NwYXRoJTIwZCUzRCUyMk01NTYuODY5JTJDMzAuNDElMjBDNTU0LjgxNCUyQzMwLjQxJTIwNTUzLjE0OCUyQzMyLjA3NiUyMDU1My4xNDglMkMzNC4xMzElMjBDNTUzLjE0OCUyQzM2LjE4NiUyMDU1NC44MTQlMkMzNy44NTIlMjA1NTYuODY5JTJDMzcuODUyJTIwQzU1OC45MjQlMkMzNy44NTIlMjA1NjAuNTklMkMzNi4xODYlMjA1NjAuNTklMkMzNC4xMzElMjBDNTYwLjU5JTJDMzIuMDc2JTIwNTU4LjkyNCUyQzMwLjQxJTIwNTU2Ljg2OSUyQzMwLjQxJTIwTTU0MSUyQzYwLjY1NyUyMEM1MzUuMTE0JTJDNjAuNjU3JTIwNTMwLjM0MiUyQzU1Ljg4NyUyMDUzMC4zNDIlMkM1MCUyMEM1MzAuMzQyJTJDNDQuMTE0JTIwNTM1LjExNCUyQzM5LjM0MiUyMDU0MSUyQzM5LjM0MiUyMEM1NDYuODg3JTJDMzkuMzQyJTIwNTUxLjY1OCUyQzQ0LjExNCUyMDU1MS42NTglMkM1MCUyMEM1NTEuNjU4JTJDNTUuODg3JTIwNTQ2Ljg4NyUyQzYwLjY1NyUyMDU0MSUyQzYwLjY1NyUyME01NDElMkMzMy44ODYlMjBDNTMyLjElMkMzMy44ODYlMjA1MjQuODg2JTJDNDEuMSUyMDUyNC44ODYlMkM1MCUyMEM1MjQuODg2JTJDNTguODk5JTIwNTMyLjElMkM2Ni4xMTMlMjA1NDElMkM2Ni4xMTMlMjBDNTQ5LjklMkM2Ni4xMTMlMjA1NTcuMTE1JTJDNTguODk5JTIwNTU3LjExNSUyQzUwJTIwQzU1Ny4xMTUlMkM0MS4xJTIwNTQ5LjklMkMzMy44ODYlMjA1NDElMkMzMy44ODYlMjBNNTY1LjM3OCUyQzYyLjEwMSUyMEM1NjUuMjQ0JTJDNjUuMDIyJTIwNTY0Ljc1NiUyQzY2LjYwNiUyMDU2NC4zNDYlMkM2Ny42NjMlMjBDNTYzLjgwMyUyQzY5LjA2JTIwNTYzLjE1NCUyQzcwLjA1NyUyMDU2Mi4xMDYlMkM3MS4xMDYlMjBDNTYxLjA1OCUyQzcyLjE1NSUyMDU2MC4wNiUyQzcyLjgwMyUyMDU1OC42NjIlMkM3My4zNDclMjBDNTU3LjYwNyUyQzczLjc1NyUyMDU1Ni4wMjElMkM3NC4yNDQlMjA1NTMuMTAyJTJDNzQuMzc4JTIwQzU0OS45NDQlMkM3NC41MjElMjA1NDguOTk3JTJDNzQuNTUyJTIwNTQxJTJDNzQuNTUyJTIwQzUzMy4wMDMlMkM3NC41NTIlMjA1MzIuMDU2JTJDNzQuNTIxJTIwNTI4Ljg5OCUyQzc0LjM3OCUyMEM1MjUuOTc5JTJDNzQuMjQ0JTIwNTI0LjM5MyUyQzczLjc1NyUyMDUyMy4zMzglMkM3My4zNDclMjBDNTIxLjk0JTJDNzIuODAzJTIwNTIwLjk0MiUyQzcyLjE1NSUyMDUxOS44OTQlMkM3MS4xMDYlMjBDNTE4Ljg0NiUyQzcwLjA1NyUyMDUxOC4xOTclMkM2OS4wNiUyMDUxNy42NTQlMkM2Ny42NjMlMjBDNTE3LjI0NCUyQzY2LjYwNiUyMDUxNi43NTUlMkM2NS4wMjIlMjA1MTYuNjIzJTJDNjIuMTAxJTIwQzUxNi40NzklMkM1OC45NDMlMjA1MTYuNDQ4JTJDNTcuOTk2JTIwNTE2LjQ0OCUyQzUwJTIwQzUxNi40NDglMkM0Mi4wMDMlMjA1MTYuNDc5JTJDNDEuMDU2JTIwNTE2LjYyMyUyQzM3Ljg5OSUyMEM1MTYuNzU1JTJDMzQuOTc4JTIwNTE3LjI0NCUyQzMzLjM5MSUyMDUxNy42NTQlMkMzMi4zMzglMjBDNTE4LjE5NyUyQzMwLjkzOCUyMDUxOC44NDYlMkMyOS45NDIlMjA1MTkuODk0JTJDMjguODk0JTIwQzUyMC45NDIlMkMyNy44NDYlMjA1MjEuOTQlMkMyNy4xOTYlMjA1MjMuMzM4JTJDMjYuNjU0JTIwQzUyNC4zOTMlMkMyNi4yNDQlMjA1MjUuOTc5JTJDMjUuNzU2JTIwNTI4Ljg5OCUyQzI1LjYyMyUyMEM1MzIuMDU3JTJDMjUuNDc5JTIwNTMzLjAwNCUyQzI1LjQ0OCUyMDU0MSUyQzI1LjQ0OCUyMEM1NDguOTk3JTJDMjUuNDQ4JTIwNTQ5Ljk0MyUyQzI1LjQ3OSUyMDU1My4xMDIlMkMyNS42MjMlMjBDNTU2LjAyMSUyQzI1Ljc1NiUyMDU1Ny42MDclMkMyNi4yNDQlMjA1NTguNjYyJTJDMjYuNjU0JTIwQzU2MC4wNiUyQzI3LjE5NiUyMDU2MS4wNTglMkMyNy44NDYlMjA1NjIuMTA2JTJDMjguODk0JTIwQzU2My4xNTQlMkMyOS45NDIlMjA1NjMuODAzJTJDMzAuOTM4JTIwNTY0LjM0NiUyQzMyLjMzOCUyMEM1NjQuNzU2JTJDMzMuMzkxJTIwNTY1LjI0NCUyQzM0Ljk3OCUyMDU2NS4zNzglMkMzNy44OTklMjBDNTY1LjUyMiUyQzQxLjA1NiUyMDU2NS41NTIlMkM0Mi4wMDMlMjA1NjUuNTUyJTJDNTAlMjBDNTY1LjU1MiUyQzU3Ljk5NiUyMDU2NS41MjIlMkM1OC45NDMlMjA1NjUuMzc4JTJDNjIuMTAxJTIwTTU3MC44MiUyQzM3LjYzMSUyMEM1NzAuNjc0JTJDMzQuNDM4JTIwNTcwLjE2NyUyQzMyLjI1OCUyMDU2OS40MjUlMkMzMC4zNDklMjBDNTY4LjY1OSUyQzI4LjM3NyUyMDU2Ny42MzMlMkMyNi43MDIlMjA1NjUuOTY1JTJDMjUuMDM1JTIwQzU2NC4yOTclMkMyMy4zNjglMjA1NjIuNjIzJTJDMjIuMzQyJTIwNTYwLjY1MiUyQzIxLjU3NSUyMEM1NTguNzQzJTJDMjAuODM0JTIwNTU2LjU2MiUyQzIwLjMyNiUyMDU1My4zNjklMkMyMC4xOCUyMEM1NTAuMTY5JTJDMjAuMDMzJTIwNTQ5LjE0OCUyQzIwJTIwNTQxJTJDMjAlMjBDNTMyLjg1MyUyQzIwJTIwNTMxLjgzMSUyQzIwLjAzMyUyMDUyOC42MzElMkMyMC4xOCUyMEM1MjUuNDM4JTJDMjAuMzI2JTIwNTIzLjI1NyUyQzIwLjgzNCUyMDUyMS4zNDklMkMyMS41NzUlMjBDNTE5LjM3NiUyQzIyLjM0MiUyMDUxNy43MDMlMkMyMy4zNjglMjA1MTYuMDM1JTJDMjUuMDM1JTIwQzUxNC4zNjglMkMyNi43MDIlMjA1MTMuMzQyJTJDMjguMzc3JTIwNTEyLjU3NCUyQzMwLjM0OSUyMEM1MTEuODM0JTJDMzIuMjU4JTIwNTExLjMyNiUyQzM0LjQzOCUyMDUxMS4xODElMkMzNy42MzElMjBDNTExLjAzNSUyQzQwLjgzMSUyMDUxMSUyQzQxLjg1MSUyMDUxMSUyQzUwJTIwQzUxMSUyQzU4LjE0NyUyMDUxMS4wMzUlMkM1OS4xNyUyMDUxMS4xODElMkM2Mi4zNjklMjBDNTExLjMyNiUyQzY1LjU2MiUyMDUxMS44MzQlMkM2Ny43NDMlMjA1MTIuNTc0JTJDNjkuNjUxJTIwQzUxMy4zNDIlMkM3MS42MjUlMjA1MTQuMzY4JTJDNzMuMjk2JTIwNTE2LjAzNSUyQzc0Ljk2NSUyMEM1MTcuNzAzJTJDNzYuNjM0JTIwNTE5LjM3NiUyQzc3LjY1OCUyMDUyMS4zNDklMkM3OC40MjUlMjBDNTIzLjI1NyUyQzc5LjE2NyUyMDUyNS40MzglMkM3OS42NzMlMjA1MjguNjMxJTJDNzkuODIlMjBDNTMxLjgzMSUyQzc5Ljk2NSUyMDUzMi44NTMlMkM4MC4wMDElMjA1NDElMkM4MC4wMDElMjBDNTQ5LjE0OCUyQzgwLjAwMSUyMDU1MC4xNjklMkM3OS45NjUlMjA1NTMuMzY5JTJDNzkuODIlMjBDNTU2LjU2MiUyQzc5LjY3MyUyMDU1OC43NDMlMkM3OS4xNjclMjA1NjAuNjUyJTJDNzguNDI1JTIwQzU2Mi42MjMlMkM3Ny42NTglMjA1NjQuMjk3JTJDNzYuNjM0JTIwNTY1Ljk2NSUyQzc0Ljk2NSUyMEM1NjcuNjMzJTJDNzMuMjk2JTIwNTY4LjY1OSUyQzcxLjYyNSUyMDU2OS40MjUlMkM2OS42NTElMjBDNTcwLjE2NyUyQzY3Ljc0MyUyMDU3MC42NzQlMkM2NS41NjIlMjA1NzAuODIlMkM2Mi4zNjklMjBDNTcwLjk2NiUyQzU5LjE3JTIwNTcxJTJDNTguMTQ3JTIwNTcxJTJDNTAlMjBDNTcxJTJDNDEuODUxJTIwNTcwLjk2NiUyQzQwLjgzMSUyMDU3MC44MiUyQzM3LjYzMSUyMiUzRSUzQyUyRnBhdGglM0UlM0MlMkZnJTNFJTNDJTJGZyUzRSUzQyUyRmclM0UlM0MlMkZzdmclM0UlM0MlMkZkaXYlM0UlM0NkaXYlMjBzdHlsZSUzRCUyMnBhZGRpbmctdG9wJTNBJTIwOHB4JTNCJTIyJTNFJTIwJTNDZGl2JTIwc3R5bGUlM0QlMjIlMjBjb2xvciUzQSUyMzM4OTdmMCUzQiUyMGZvbnQtZmFtaWx5JTNBQXJpYWwlMkNzYW5zLXNlcmlmJTNCJTIwZm9udC1zaXplJTNBMTRweCUzQiUyMGZvbnQtc3R5bGUlM0Fub3JtYWwlM0IlMjBmb250LXdlaWdodCUzQTU1MCUzQiUyMGxpbmUtaGVpZ2h0JTNBMThweCUzQiUyMiUzRVZpZXclMjB0aGlzJTIwcG9zdCUyMG9uJTIwSW5zdGFncmFtJTNDJTJGZGl2JTNFJTNDJTJGZGl2JTNFJTNDZGl2JTIwc3R5bGUlM0QlMjJwYWRkaW5nJTNBJTIwMTIuNSUyNSUyMDAlM0IlMjIlM0UlM0MlMkZkaXYlM0UlMjAlM0NkaXYlMjBzdHlsZSUzRCUyMmRpc3BsYXklM0ElMjBmbGV4JTNCJTIwZmxleC1kaXJlY3Rpb24lM0ElMjByb3clM0IlMjBtYXJnaW4tYm90dG9tJTNBJTIwMTRweCUzQiUyMGFsaWduLWl0ZW1zJTNBJTIwY2VudGVyJTNCJTIyJTNFJTNDZGl2JTNFJTIwJTNDZGl2JTIwc3R5bGUlM0QlMjJiYWNrZ3JvdW5kLWNvbG9yJTNBJTIwJTIzRjRGNEY0JTNCJTIwYm9yZGVyLXJhZGl1cyUzQSUyMDUwJTI1JTNCJTIwaGVpZ2h0JTNBJTIwMTIuNXB4JTNCJTIwd2lkdGglM0ElMjAxMi41cHglM0IlMjB0cmFuc2Zvcm0lM0ElMjB0cmFuc2xhdGVYJTI4MHB4JTI5JTIwdHJhbnNsYXRlWSUyODdweCUyOSUzQiUyMiUzRSUzQyUyRmRpdiUzRSUyMCUzQ2RpdiUyMHN0eWxlJTNEJTIyYmFja2dyb3VuZC1jb2xvciUzQSUyMCUyM0Y0RjRGNCUzQiUyMGhlaWdodCUzQSUyMDEyLjVweCUzQiUyMHRyYW5zZm9ybSUzQSUyMHJvdGF0ZSUyOC00NWRlZyUyOSUyMHRyYW5zbGF0ZVglMjgzcHglMjklMjB0cmFuc2xhdGVZJTI4MXB4JTI5JTNCJTIwd2lkdGglM0ElMjAxMi41cHglM0IlMjBmbGV4LWdyb3clM0ElMjAwJTNCJTIwbWFyZ2luLXJpZ2h0JTNBJTIwMTRweCUzQiUyMG1hcmdpbi1sZWZ0JTNBJTIwMnB4JTNCJTIyJTNFJTNDJTJGZGl2JTNFJTIwJTNDZGl2JTIwc3R5bGUlM0QlMjJiYWNrZ3JvdW5kLWNvbG9yJTNBJTIwJTIzRjRGNEY0JTNCJTIwYm9yZGVyLXJhZGl1cyUzQSUyMDUwJTI1JTNCJTIwaGVpZ2h0JTNBJTIwMTIuNXB4JTNCJTIwd2lkdGglM0ElMjAxMi41cHglM0IlMjB0cmFuc2Zvcm0lM0ElMjB0cmFuc2xhdGVYJTI4OXB4JTI5JTIwdHJhbnNsYXRlWSUyOC0xOHB4JTI5JTNCJTIyJTNFJTNDJTJGZGl2JTNFJTNDJTJGZGl2JTNFJTNDZGl2JTIwc3R5bGUlM0QlMjJtYXJnaW4tbGVmdCUzQSUyMDhweCUzQiUyMiUzRSUyMCUzQ2RpdiUyMHN0eWxlJTNEJTIyJTIwYmFja2dyb3VuZC1jb2xvciUzQSUyMCUyM0Y0RjRGNCUzQiUyMGJvcmRlci1yYWRpdXMlM0ElMjA1MCUyNSUzQiUyMGZsZXgtZ3JvdyUzQSUyMDAlM0IlMjBoZWlnaHQlM0ElMjAyMHB4JTNCJTIwd2lkdGglM0ElMjAyMHB4JTNCJTIyJTNFJTNDJTJGZGl2JTNFJTIwJTNDZGl2JTIwc3R5bGUlM0QlMjIlMjB3aWR0aCUzQSUyMDAlM0IlMjBoZWlnaHQlM0ElMjAwJTNCJTIwYm9yZGVyLXRvcCUzQSUyMDJweCUyMHNvbGlkJTIwdHJhbnNwYXJlbnQlM0IlMjBib3JkZXItbGVmdCUzQSUyMDZweCUyMHNvbGlkJTIwJTIzZjRmNGY0JTNCJTIwYm9yZGVyLWJvdHRvbSUzQSUyMDJweCUyMHNvbGlkJTIwdHJhbnNwYXJlbnQlM0IlMjB0cmFuc2Zvcm0lM0ElMjB0cmFuc2xhdGVYJTI4MTZweCUyOSUyMHRyYW5zbGF0ZVklMjgtNHB4JTI5JTIwcm90YXRlJTI4MzBkZWclMjklMjIlM0UlM0MlMkZkaXYlM0UlM0MlMkZkaXYlM0UlM0NkaXYlMjBzdHlsZSUzRCUyMm1hcmdpbi1sZWZ0JTNBJTIwYXV0byUzQiUyMiUzRSUyMCUzQ2RpdiUyMHN0eWxlJTNEJTIyJTIwd2lkdGglM0ElMjAwcHglM0IlMjBib3JkZXItdG9wJTNBJTIwOHB4JTIwc29saWQlMjAlMjNGNEY0RjQlM0IlMjBib3JkZXItcmlnaHQlM0ElMjA4cHglMjBzb2xpZCUyMHRyYW5zcGFyZW50JTNCJTIwdHJhbnNmb3JtJTNBJTIwdHJhbnNsYXRlWSUyODE2cHglMjklM0IlMjIlM0UlM0MlMkZkaXYlM0UlMjAlM0NkaXYlMjBzdHlsZSUzRCUyMiUyMGJhY2tncm91bmQtY29sb3IlM0ElMjAlMjNGNEY0RjQlM0IlMjBmbGV4LWdyb3clM0ElMjAwJTNCJTIwaGVpZ2h0JTNBJTIwMTJweCUzQiUyMHdpZHRoJTNBJTIwMTZweCUzQiUyMHRyYW5zZm9ybSUzQSUyMHRyYW5zbGF0ZVklMjgtNHB4JTI5JTNCJTIyJTNFJTNDJTJGZGl2JTNFJTIwJTNDZGl2JTIwc3R5bGUlM0QlMjIlMjB3aWR0aCUzQSUyMDAlM0IlMjBoZWlnaHQlM0ElMjAwJTNCJTIwYm9yZGVyLXRvcCUzQSUyMDhweCUyMHNvbGlkJTIwJTIzRjRGNEY0JTNCJTIwYm9yZGVyLWxlZnQlM0ElMjA4cHglMjBzb2xpZCUyMHRyYW5zcGFyZW50JTNCJTIwdHJhbnNmb3JtJTNBJTIwdHJhbnNsYXRlWSUyOC00cHglMjklMjB0cmFuc2xhdGVYJTI4OHB4JTI5JTNCJTIyJTNFJTNDJTJGZGl2JTNFJTNDJTJGZGl2JTNFJTNDJTJGZGl2JTNFJTIwJTNDZGl2JTIwc3R5bGUlM0QlMjJkaXNwbGF5JTNBJTIwZmxleCUzQiUyMGZsZXgtZGlyZWN0aW9uJTNBJTIwY29sdW1uJTNCJTIwZmxleC1ncm93JTNBJTIwMSUzQiUyMGp1c3RpZnktY29udGVudCUzQSUyMGNlbnRlciUzQiUyMG1hcmdpbi1ib3R0b20lM0ElMjAyNHB4JTNCJTIyJTNFJTIwJTNDZGl2JTIwc3R5bGUlM0QlMjIlMjBiYWNrZ3JvdW5kLWNvbG9yJTNBJTIwJTIzRjRGNEY0JTNCJTIwYm9yZGVyLXJhZGl1cyUzQSUyMDRweCUzQiUyMGZsZXgtZ3JvdyUzQSUyMDAlM0IlMjBoZWlnaHQlM0ElMjAxNHB4JTNCJTIwbWFyZ2luLWJvdHRvbSUzQSUyMDZweCUzQiUyMHdpZHRoJTNBJTIwMjI0cHglM0IlMjIlM0UlM0MlMkZkaXYlM0UlMjAlM0NkaXYlMjBzdHlsZSUzRCUyMiUyMGJhY2tncm91bmQtY29sb3IlM0ElMjAlMjNGNEY0RjQlM0IlMjBib3JkZXItcmFkaXVzJTNBJTIwNHB4JTNCJTIwZmxleC1ncm93JTNBJTIwMCUzQiUyMGhlaWdodCUzQSUyMDE0cHglM0IlMjB3aWR0aCUzQSUyMDE0NHB4JTNCJTIyJTNFJTNDJTJGZGl2JTNFJTNDJTJGZGl2JTNFJTNDJTJGYSUzRSUzQ3AlMjBzdHlsZSUzRCUyMiUyMGNvbG9yJTNBJTIzYzljOGNkJTNCJTIwZm9udC1mYW1pbHklM0FBcmlhbCUyQ3NhbnMtc2VyaWYlM0IlMjBmb250LXNpemUlM0ExNHB4JTNCJTIwbGluZS1oZWlnaHQlM0ExN3B4JTNCJTIwbWFyZ2luLWJvdHRvbSUzQTAlM0IlMjBtYXJnaW4tdG9wJTNBOHB4JTNCJTIwb3ZlcmZsb3clM0FoaWRkZW4lM0IlMjBwYWRkaW5nJTNBOHB4JTIwMCUyMDdweCUzQiUyMHRleHQtYWxpZ24lM0FjZW50ZXIlM0IlMjB0ZXh0LW92ZXJmbG93JTNBZWxsaXBzaXMlM0IlMjB3aGl0ZS1zcGFjZSUzQW5vd3JhcCUzQiUyMiUzRSUzQ2ElMjBocmVmJTNEJTIyaHR0cHMlM0ElMkYlMkZ3d3cuaW5zdGFncmFtLmNvbSUyRnJlZWwlMkZDMGhaY3E0cnVmWSUyRiUzRnV0bV9zb3VyY2UlM0RpZ19lbWJlZCUyNmFtcCUzQnV0bV9jYW1wYWlnbiUzRGxvYWRpbmclMjIlMjBzdHlsZSUzRCUyMiUyMGNvbG9yJTNBJTIzYzljOGNkJTNCJTIwZm9udC1mYW1pbHklM0FBcmlhbCUyQ3NhbnMtc2VyaWYlM0IlMjBmb250LXNpemUlM0ExNHB4JTNCJTIwZm9udC1zdHlsZSUzQW5vcm1hbCUzQiUyMGZvbnQtd2VpZ2h0JTNBbm9ybWFsJTNCJTIwbGluZS1oZWlnaHQlM0ExN3B4JTNCJTIwdGV4dC1kZWNvcmF0aW9uJTNBbm9uZSUzQiUyMiUyMHRhcmdldCUzRCUyMl9ibGFuayUyMiUzRUElMjBwb3N0JTIwc2hhcmVkJTIwYnklMjBMZWRlcmVyJTIwVGltZXBpZWNlcyUyMCUyOCU0MGxlZGVyZXJ0aW1lcGllY2VzJTI5JTNDJTJGYSUzRSUzQyUyRnAlM0UlM0MlMkZkaXYlM0UlM0MlMkZibG9ja3F1b3RlJTNFJTIwJTNDc2NyaXB0JTIwYXN5bmMlMjBzcmMlM0QlMjIlMkYlMkZ3d3cuaW5zdGFncmFtLmNvbSUyRmVtYmVkLmpzJTIyJTNFJTNDJTJGc2NyaXB0JTNF[/vc_raw_html][vc_column_inner width=”1/6″]

Lederer is not a new face on our platform. We wrote about the inner workings of the Central Impulse Chronometer

here, and if you haven’t had the pleasure of knowing the man behind the watch, we threw in a little introduction there too. Now, on to the technical bits.

The Central Impulse Chronometer InVerto maintains its 44mm diameter but is a tad slimmer at 11.5mm compared to the previous 12.2mm due to the absence of a dial. The standard version was a watch that wore its robust technical character lightly; on the face of it was a guilloche dial with a pair of openworked seconds counters that showcased the twin escape wheels.

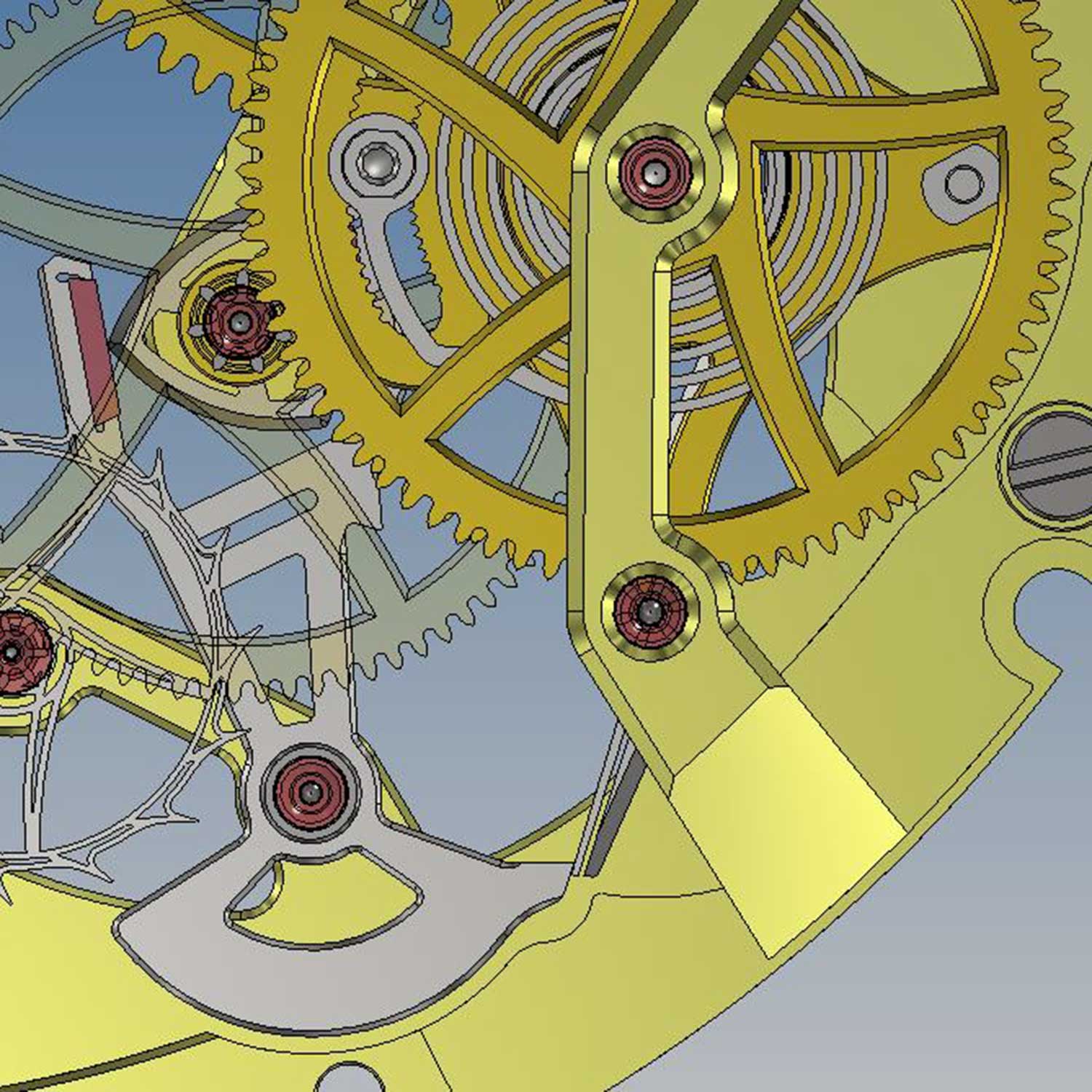

The movement itself, while being a demonstration of traditional watchmaking techniques, has a modern appearance due to the angularity of the bridgework and the spoked wheels. As such, by showcasing the movement on the front, the inVerto takes on a completely different look and feel.

The case is DLC-coated steel, and the bridges and main plate themselves are similarly coated in black, offering a striking contrast with the gilded components.

Central Impulse Chronometer InVerto

Despite being darker and less prominent, no concessions have been made in terms of finishing. The bridges have a frosted finish with a distinctive raised lip that is straight-grained on the surface, polished and beveled by hand on the edges while the unique wheel spokes showcase numerous internal angles.

The hour and minute hands have a complex form that could only be crafted by hand. Likewise, they feature black polishing and frosting.

Bevelling on the barrel bridge

Applying anglage on the second wheel bridge

Finishing on the remontoir bridges

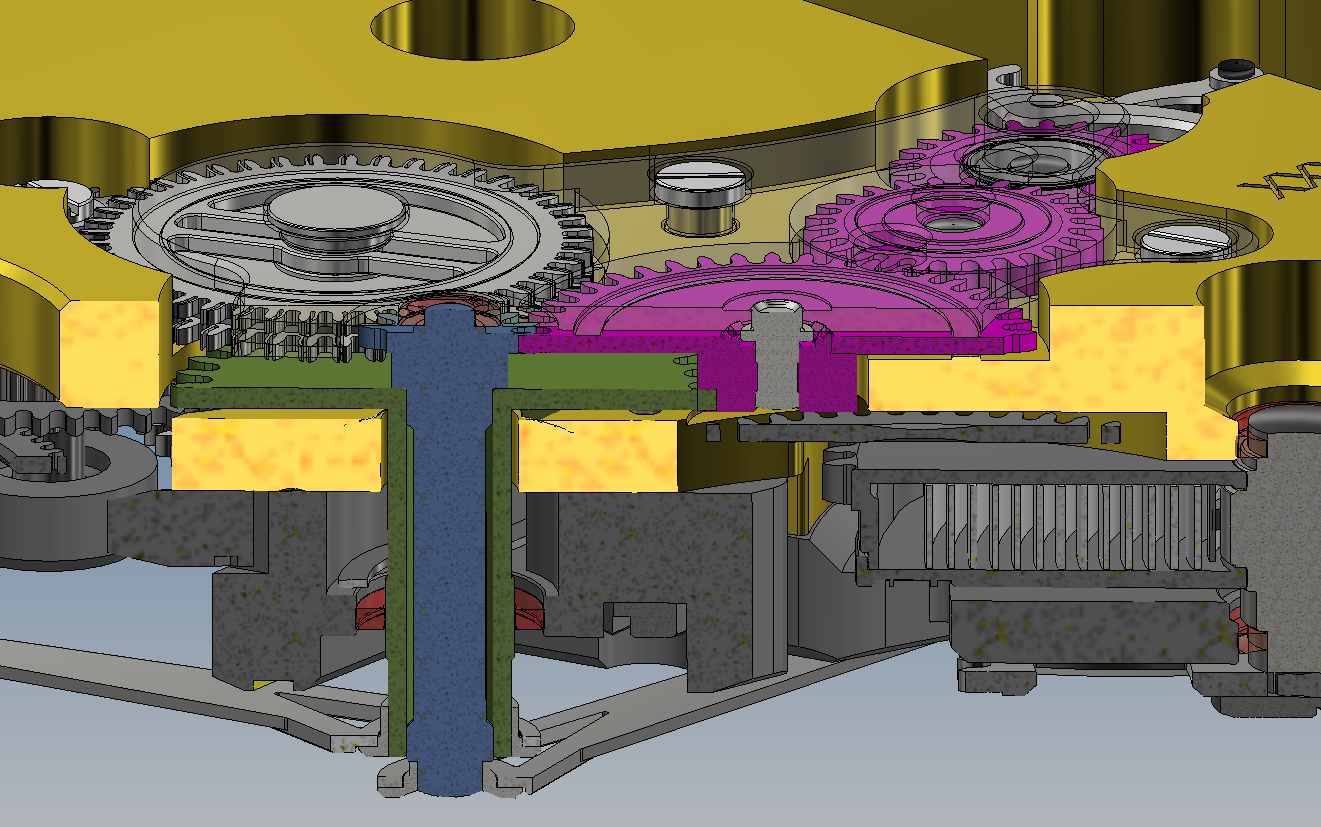

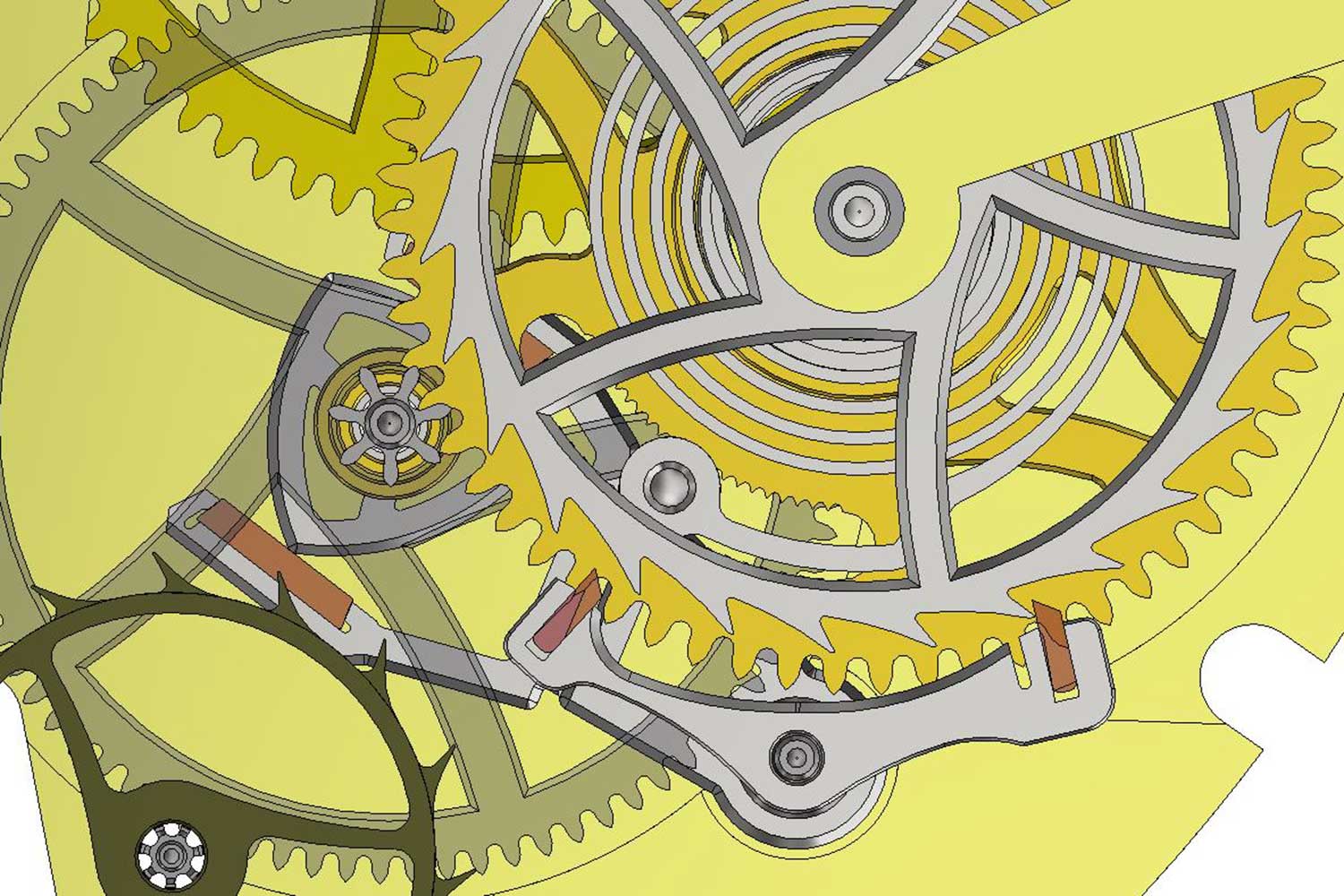

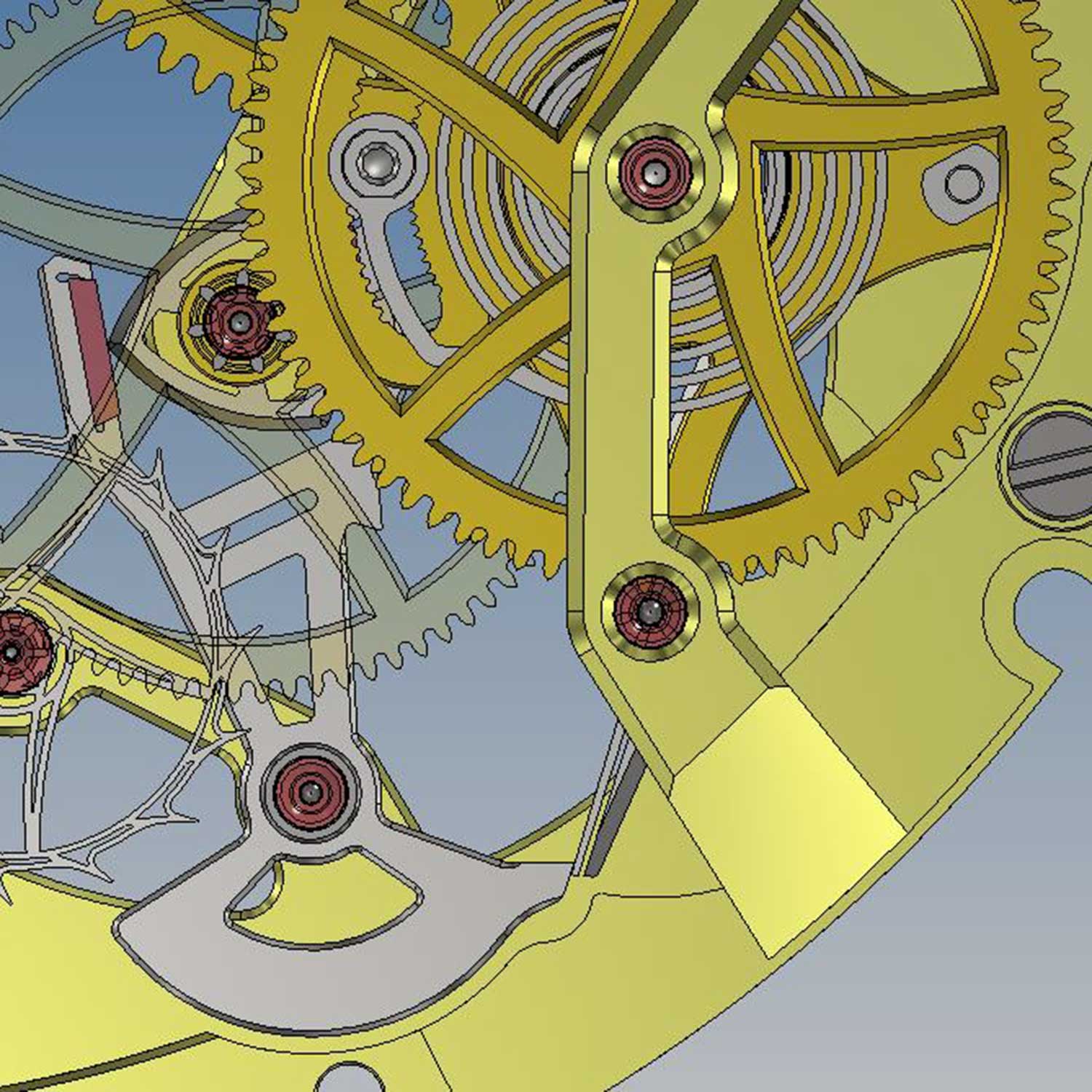

The movement is mechanically almost identical to the standard version, save for the display mechanism. In its original form, it already has an indirectly driven minutes. Typically, inverting the movement requires additional gearing to drive the hands in the right direction. However, due to the nature of the movement —with two opposing rotating trains — the second wheel (normally referred to as the center wheel) from the other train can be used to drive the motion works. Specifically, it drives the minute wheel directly, and the minute wheel pinion drives the hour wheel as usual. Nevertheless, the center pinion and minute axle had to be elongated to reach the front of the watch.

Additionally, as the gear train is released every 10 seconds by the remontoir, it potentially causes the minute hand to leap forward. Thus, the gears that connect the other second wheel to the center pinion has an anti-backlash design, featuring elastic teeth, essentially removing play within the motion works to ensure precise motion of the minute hand.

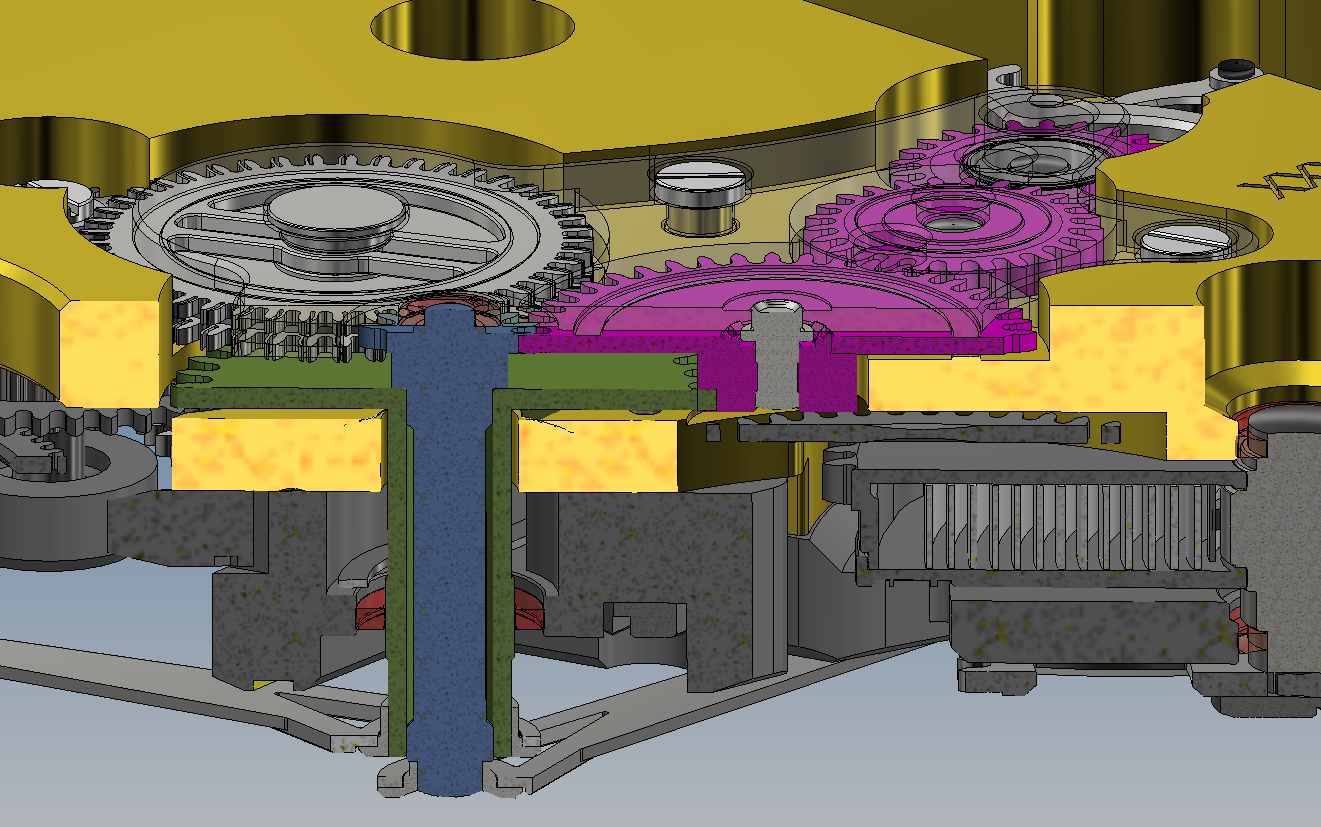

Minute wheel (in pink) driven directly by the second wheel (traditionally the center wheel). A pair of anti-backlash gears next to the center pinion eliminates play within the motion works to prevent any sidestep of the minute hand as the gear train is released by the remontoir every 10 seconds

Noticeably absent from the dial is the seconds hand. Instead, it is located on the solid case back. As the movement had to be COSC-certified, during which rates are checked by the physical location of the seconds hand, a conventional dial had to be created and submitted for testing. Likewise, as the movement have two counter-rotating fourth wheels, the wheel rotating in a clockwise direction is fitted with a seconds hand.

In-house developed free-sprung balance attached to an overcoil hairspring

The movement has a 42-hour power reserve. Both mainspring barrels are wound via a crown wheel with integrated triple winding clicks. However, as the escape wheels must be driven in opposite directions, an intermediate wheel is added between the crown wheel and the second barrel to reverse the direction of rotation. The going trains are entirely symmetrical, with the remontoir spring visible on each of the third wheel.

The balance is free sprung with eight inertial weights and consistent with the watch’s overarching commitment to chronometric performance, it is attached to an overcoil hairspring.

With the exception of the case, crystals and springs, all components of the watch were designed and produced in-house at Lederer’s workshop in St. Blaise.

Independent Double Wheel Escapement

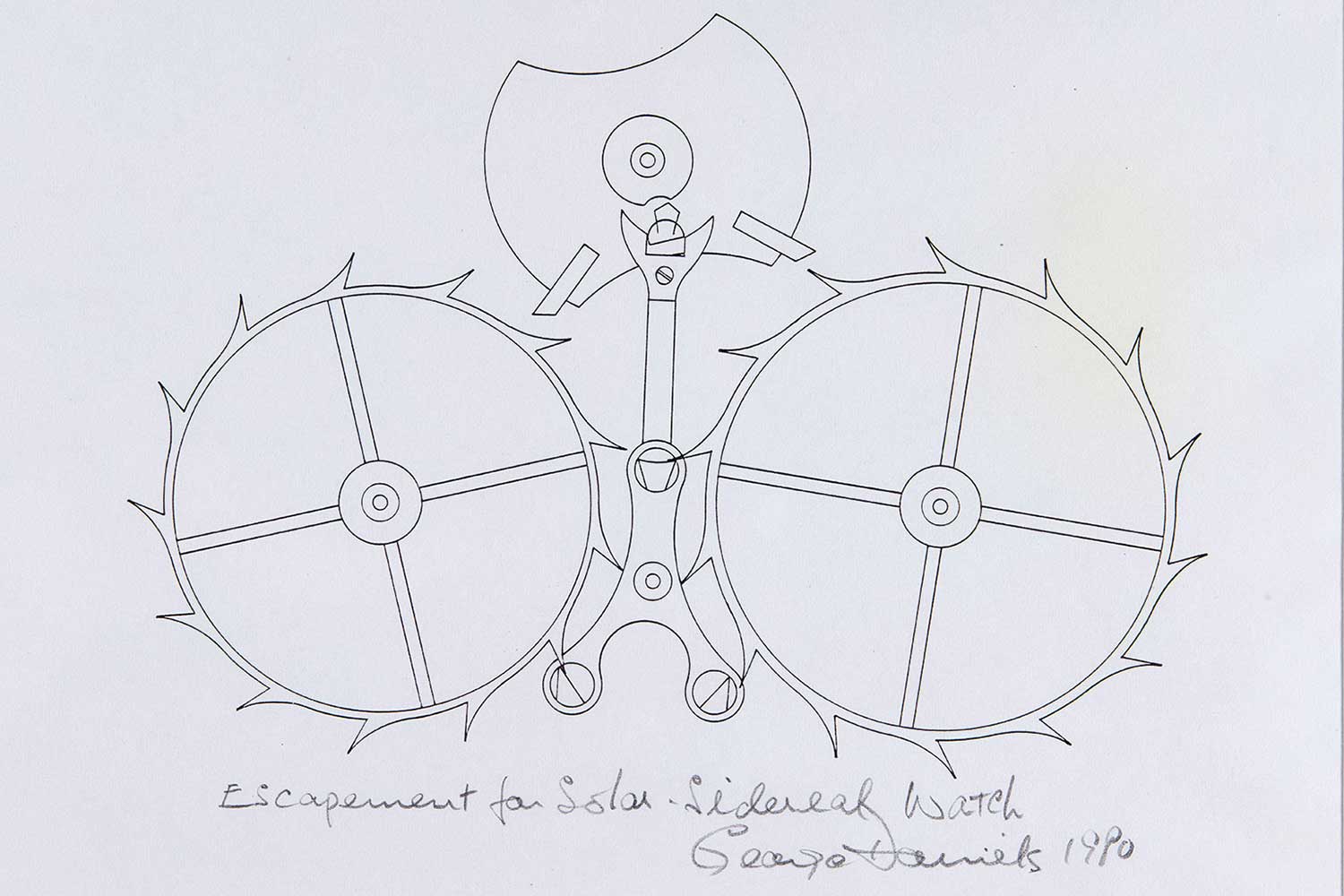

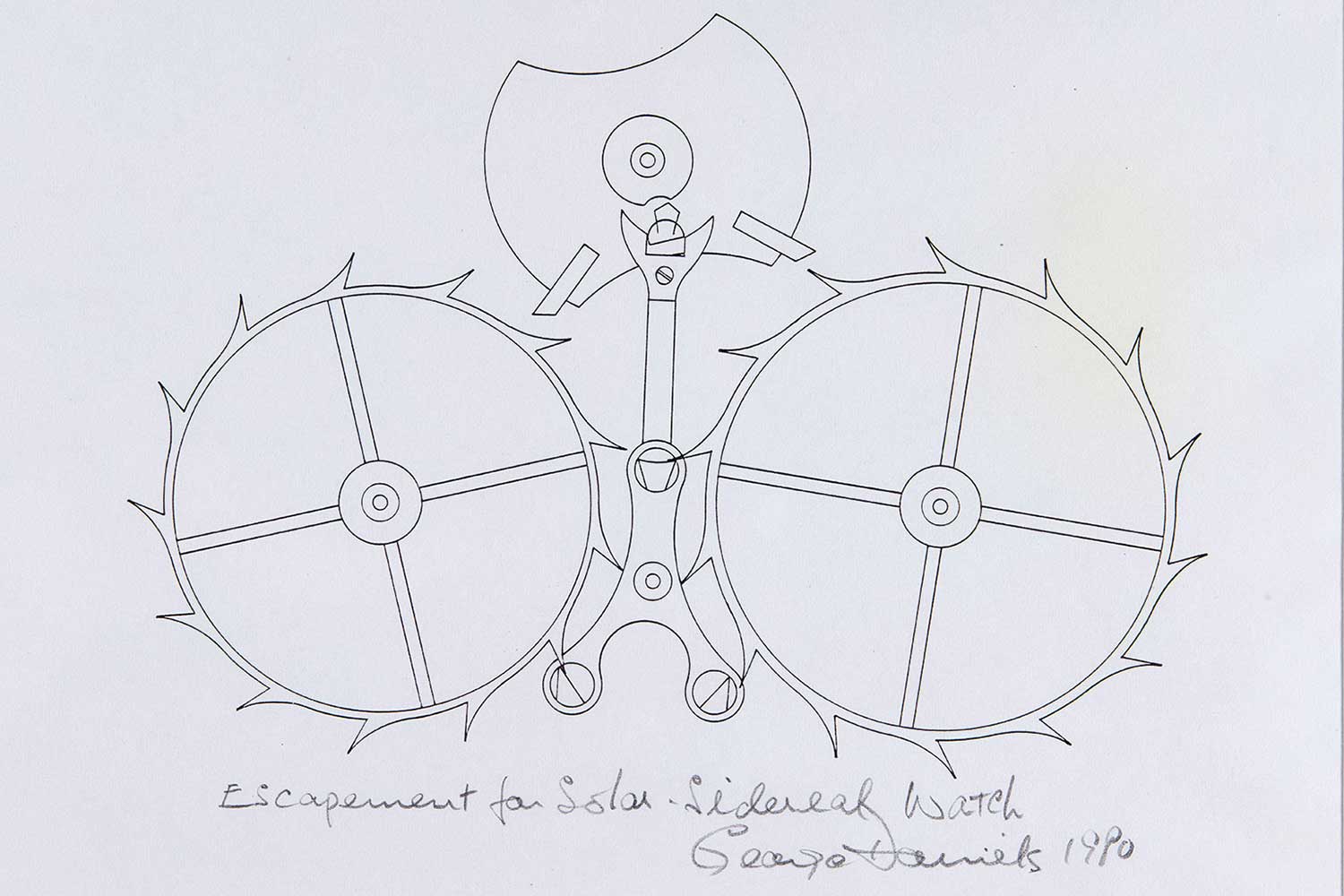

Now that the movement is the dial, it is worth recapping the main principles of the Independent Double Wheel escapement in brief. The independent double wheel escapement was invented by George Daniels in 1976 at the behest of American industrialist and watch collector Seth Atwood, who wanted a timepiece with an entirely novel escapement.

The independent double wheel escapement was designed to realised the advantages of Breguet’s natural escapement while eliminating its weaknesses.

At the beginning of the 19th century, Breguet, having recognized the drawbacks of the then-newly invented lever escapement, primarily its need for lubrication, sought to design a superior escapement that merged the dual-impulse, self-starting capability of the lever and the direct-impulse, friction-free operation of the detent escapement without either of their shortcomings. Characterised by two counter-rotating wheels, the natural escapement was so called because the impulses given are direct at each vibration, eliminating the need for lubrication.

Notably, Breguet experimented with various configurations of the natural escapement such as having the two escape wheels mounted on two additional coupled wheels that were directly driven by the gear train. In this configuration, the two escape wheels are not directly geared and each serves purely to lock and unlock the detent alternately.

Today, natural escapements that are based on this design are the F.P. Journe High performance Bi-axial escapement and the Kari Voutilainen Double Direct Impulse escapement. However, this approach has its drawbacks, notably increased inertia from the additional wheels and backlash in the teeth of the meshing wheels, resulting in instability.

The other notable configuration Breguet arrived at is to have the first escape wheel drive the second escape wheel directly with traditional teeth while a set of vertical pins on each escape wheel would lock and unlock the detent, eliminating the need for extra gearing in the going train. This design inspired the Laurent Ferrier Natural Escapement which also features vertical teeth on each escape wheel as well as the Ulysse Nardin Dual Direct Escapement, which thanks to DRIE technology, integrated Breguet’s two-level escape wheel construction into a single plane.

While advances in material science and modern technology have made this construction possible, Breguet never fully overcame the issue of play between the escape wheels during his time and abandoned the idea to focus on improving the lever.

The earliest natural escapement in Breguet's pocket watch no. 1135. Each escape wheel is constructed with conventional teeth as well as vertical pins. The conventional teeth allows the first escape wheel to drive the second directly while the pins are responsible for the locking and unlocking of the detent

As mentioned, the natural escapement, when assessed independently, is the most efficient escapement for a wristwatch as it is the only escapement that delivers two direct impulses to the balance wheel at each cycle. In contrast, the lever escapement offers two indirect impulses, while both the Co-axial and the Grand Seiko Dual Impulse escapements rely on combined impulse system of having one direct and one indirect impulse.

Alas, an escapement does not operate in a vacuum. In the absence of contemporary lightweight materials like silicon, challenges related to inertia and backlash remain unresolved.

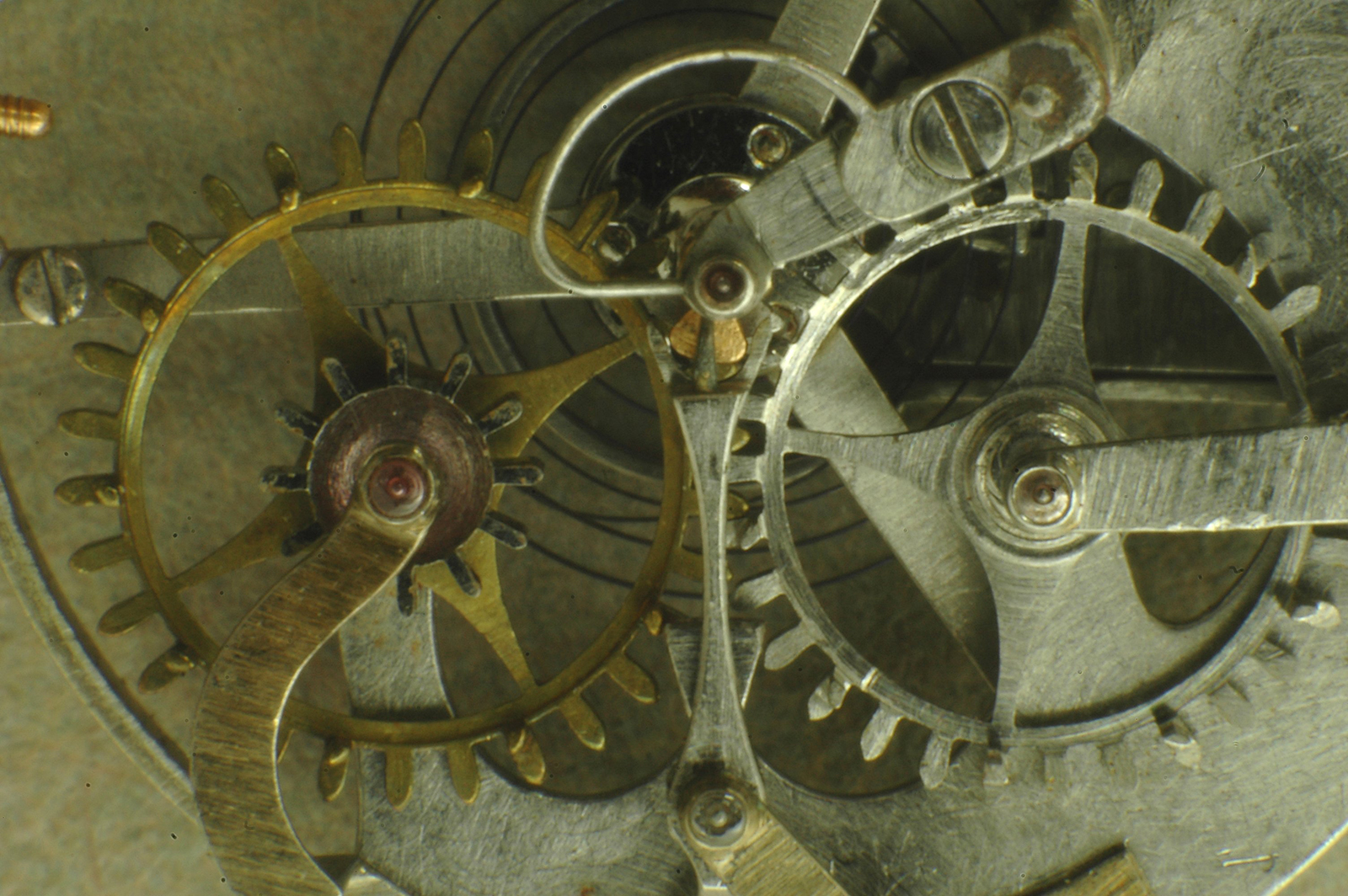

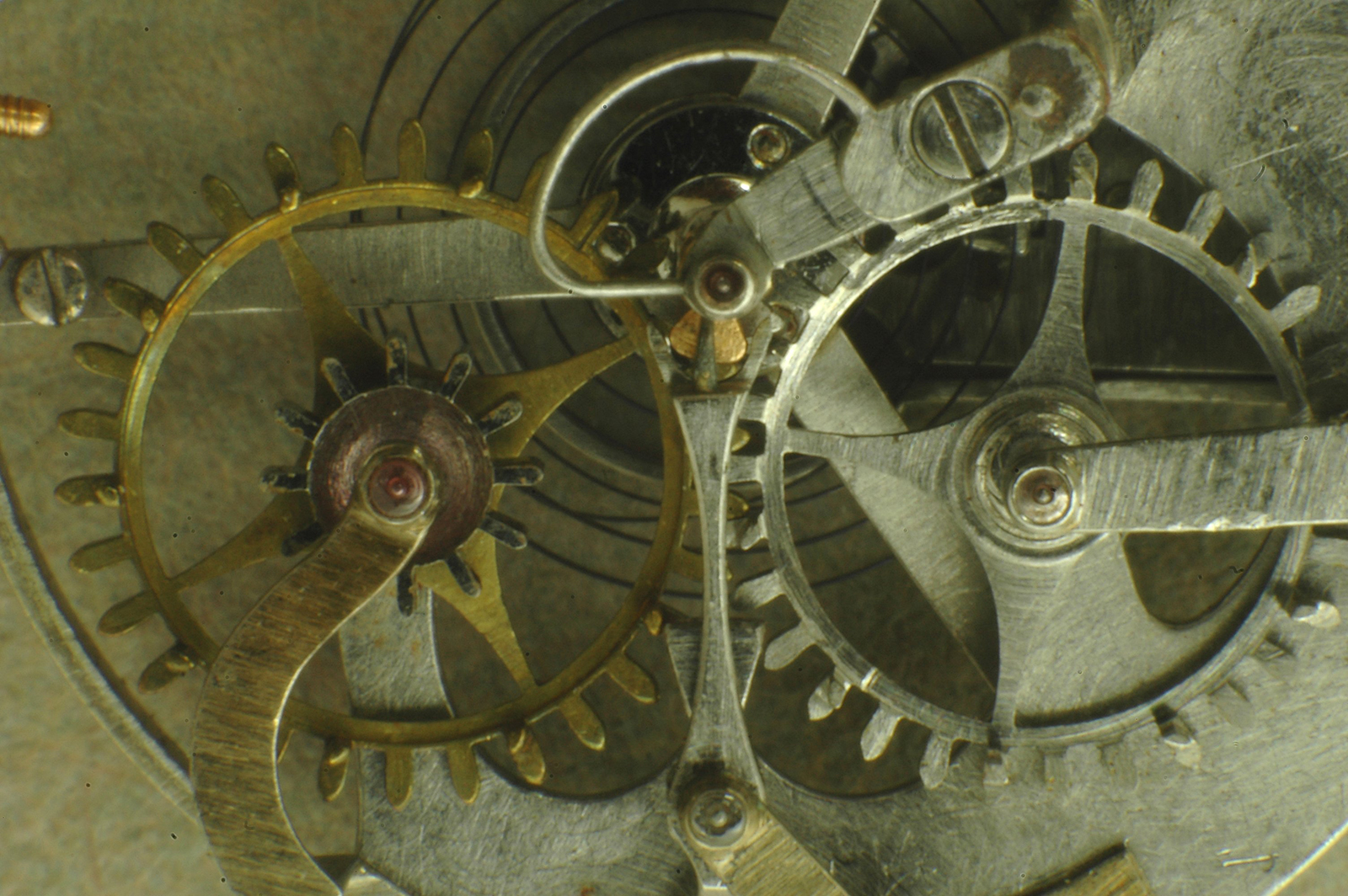

The double-wheel chronometer escapement in the Space Traveller (Image: The Hour Glass)

Daniels’ solution was thus to allow each escape wheel to be driven by its own gear train and mainspring, eliminating the geared connection in the previous two approaches. As each mainspring powers only one escape wheel, as with a standard movement, transmission efficiency is significantly greater.

Although Daniels was captivated by the qualities of the independent double-wheel escapement, incorporating it in a total of six watches including the Space Traveller I and II, he had identified several inherent disadvantages. In his book Watchmaking, he noted that the double unlocking at each vibration consumes balance energy and above all, he believed that its complex construction could not be sufficiently miniaturised in a wristwatch.

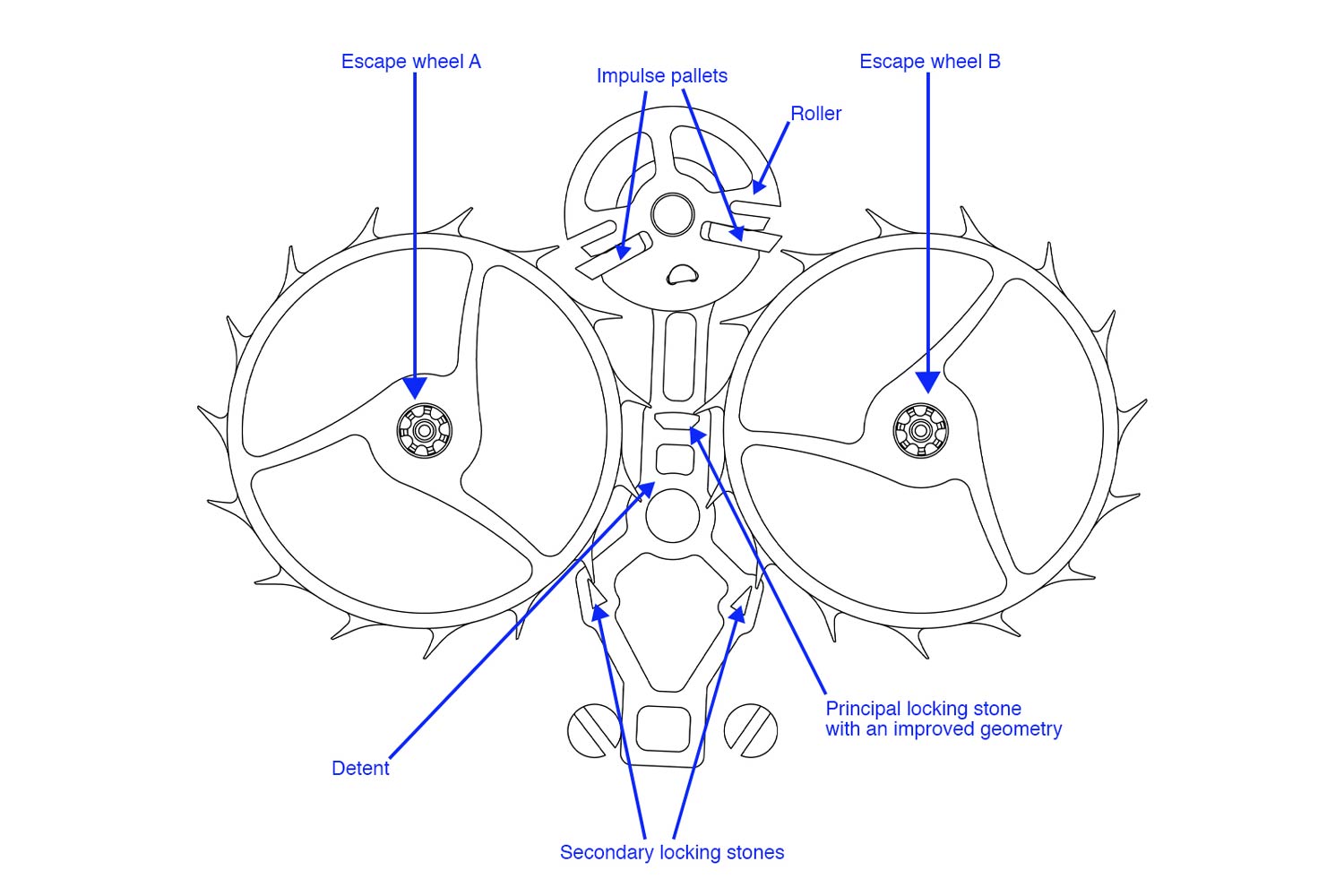

Since then, both Bernhard Lederer and Charles Frodsham have accomplished this, albeit in relatively large cases due to the nature of the movement. Both have increased the beat frequency to 3Hz but Frodsham’s execution is closer to Daniels’ original design while Lederer’s design is an improved version that sought to address the weakness identified by Daniels, namely energy losses.

In Daniels’ design, the shape of the principal locking stone has two sharp upward-pointing edges to lock the escape wheel on either side. This produces a lifting angle that potentially causes a recoil – an undesired backward movement – of the escape wheels as they are liberated from the detent.

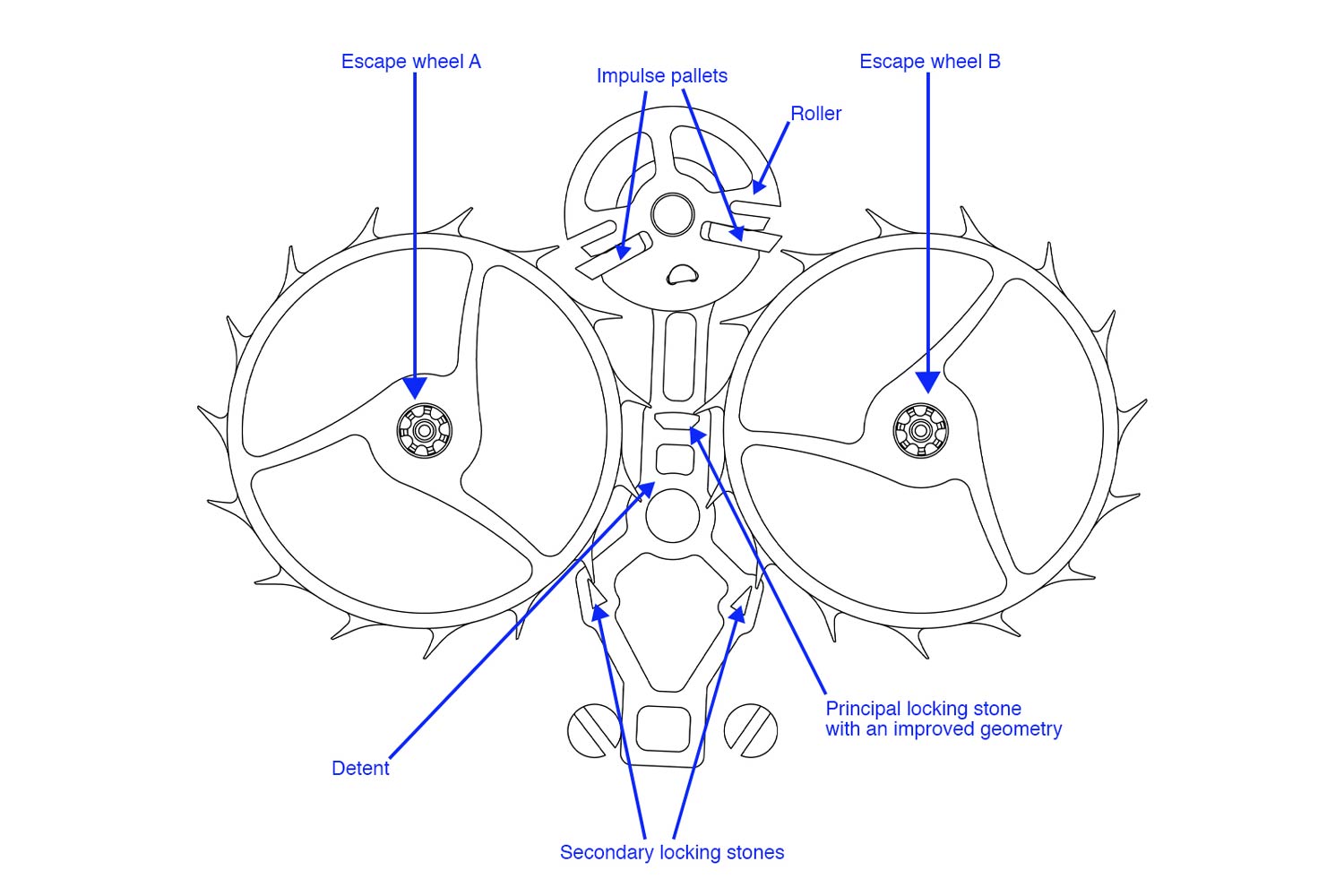

Lederer solved this by refining the shape of the locking stone, eliminating the upward curve. Additionally, he added two extra impulse surfaces on each side to maintain efficiency at low amplitude.

Drawing of George Daniels' escapement

Bernhard Lederer's version of the independent double-wheel escapement

At low amplitudes, a tooth of the escape wheel that previously rested on the principal locking stone moves across this tiny sloped surface. As it does, it nudges the detent sideways, prompting a rotation of the double roller.

This rotation ensures that the impulse pallet consistently remains positioned in front of the tooth responsible for direct impulse transmission.

However, as the balance reaches an amplitude of about 80 degrees, the rotational movement of the detent becomes rapid. At this point, the tooth that was previously in contact with the principal locking stone no longer reaches this additional lateral surface.

This solution essentially ensures that the impulse pallet remains correctly aligned with the tooth for effective impulse transmission at varying levels of amplitude.

The twin escape wheels as well as detent lever in Lederer’s escapement was further designed for low inertia. They are made from titanium, which was chosen for its optimal combination of lightness and strength.

Due to the unique operating principles of the natural escapement, the COSC had to set up a special working station where the watches are evaluated manually as the standard software or automated testing systems that are used for movements with Swiss lever escapements cannot fully assessed a watch with a natural escapement. This is because as the balance wheel oscillates, each escape wheel in a natural escapement is released at alternating intervals, resulting in both second hands taking turns to move in an alternating manner while only one seconds hand undergoes assessment at the COSC.

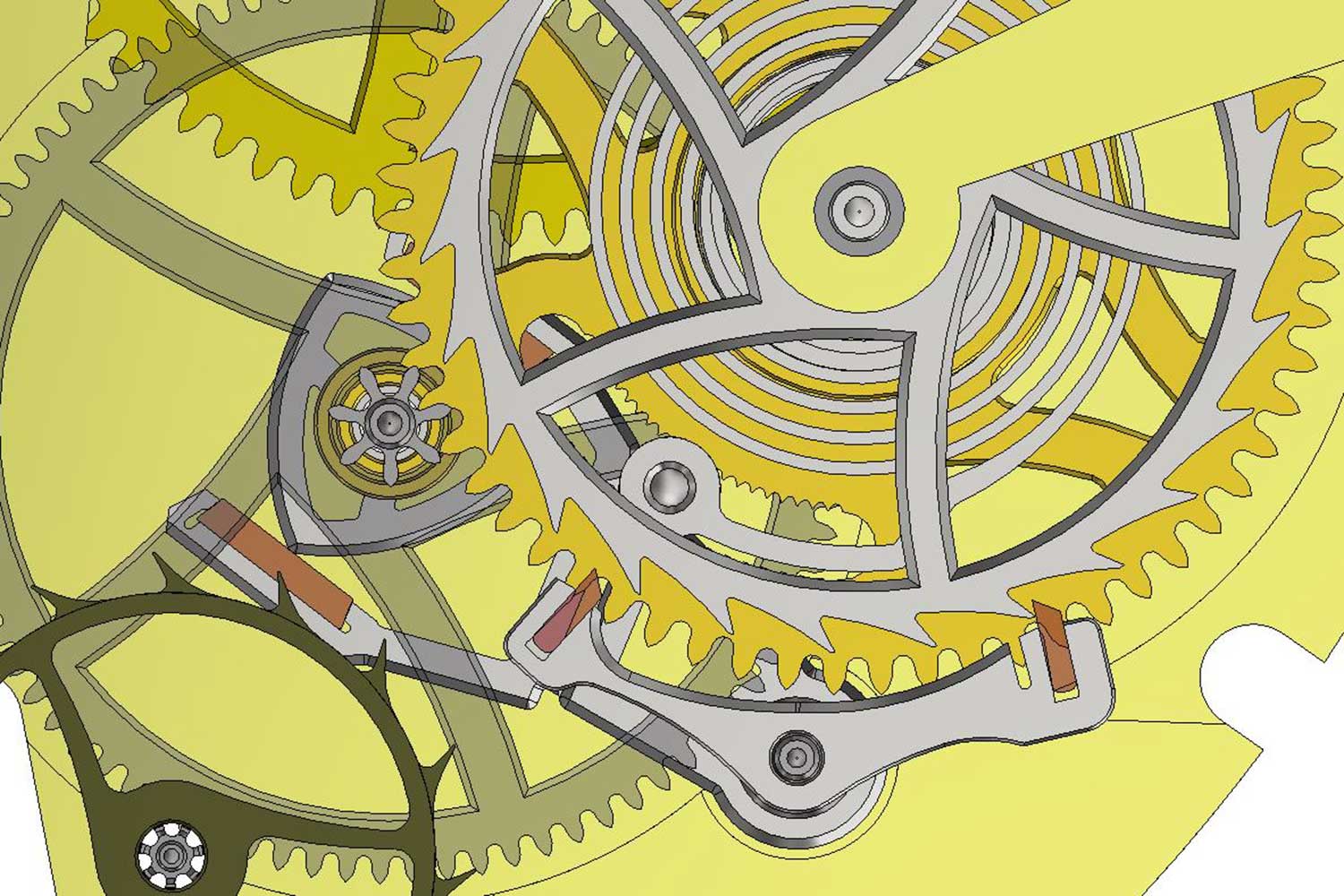

Both gear trains are equipped with a 10-second remontoir that operate in alternating cycles, with each set releasing every five seconds. While the basis for a remontoir arises from the basic principles of a mechanical movement in that the energy produced by the mainspring varies across its state of wind, it is especially advantageous for managing high torque as well as for an escapement that is dependent on the parity of power between two separate gear trains.

In the initial prototype of the Central Impulse Chronometer, each remontoir mechanism is of a traditional design, consisting of a ratchet stop wheel located prominently on each third wheel. This ratchet wheel is locked and unlocked by a remontoir anchor that is connected to a fork.

The motion of the fork is in turn controlled by a Reuleaux triangle on the fourth wheel. Each time the Reuleaux triangle turns, it triggers the unlocking of one of the teeth on the remontoir stop wheel through the motion of the anchor.

As this tooth is released and the remontoir stop wheel snaps forward, the remontoir spring beneath is wound up.

The remontoir mechanism in the original 2021 prototype. It employed a ratchet stop wheel that is locked and unlocked by an anchor, to which a jeweled fork governed by a Reuleaux triangle is attached

However, later Bernhard Lederer observed that when the watch is wound to its maximum capacity, there’s more pressure and hence friction between the teeth of the remontoir wheel and the anchor pallets. But as the watch approaches the end of its power reserve, this friction between the contact points gradually diminishes.

While this might seem extremely obsessive not just to the casual observer but probably anyone, Bernhard Lederer, the perfectionist that he is, found this unacceptable. Hence, in the production model, he added an additional axle next to the remontoir wheel which now features regular cycloidal teeth.

On this axle is a two-prong stop wheel (a flywheel) that is unlocked every 10 seconds by a finger linked to the fork. The remontoir wheel to stop wheel ratio is now 9:1, resulting in negligible frictional effects.

The improved remontoir mechanism has a simplified setup. The stop wheel is now a flywheel that is located on an additional axle. It is locked and unlocked by a finger on the free end of the fork

Remontoir wheel and coil spring

The Central Impulse Chronometer stands as a singular and profoundly obsessive realization of the independent double wheel escapement, and the inVerto is an iteration that offers an interesting and distinct perspective while being slimmer. While it wears its chronometric innovations on its sleeve, it becomes less of an expression of utility but a self-assured and enjoyable demonstration of mechanics as art.

Both versions will no doubt have its own admirers and in the grand scheme of things, the differences in aesthetics may feel like hair splitting amidst the wealth of horological content present.

Central Impulse Chronometer InVerto

For inquiries, contact [email protected] or visit Bernhard Lederer’s authorized retail partners. Bernhard Lederer Central Impulse Chronometer InvertoMovement: Manual winding caliber 9018; 42-hour power reserve; 3 Hz (21,600 vph)

Functions: Hours, minutes and seconds (on the back)

Case: 44mm x 11.5mm; DLC-coated stainless steel; water resistant to 30m

Price: CHF 150,000 before tax

Availability: Limited to 18 pieces