A Closer Look: F.P. Journe Chronomètre Furtif

Reviews

A Closer Look: F.P. Journe Chronomètre Furtif

Following the Chronomètre Furtif Bleu, a unique creation with a tantalum case and bracelet made for Only Watch 2024, F.P. Journe has now introduced the production version as part of the lineSport collection. The Chronomètre Furtif is exceptionally unique for an F.P. Journe watch; it is, as its name suggests, designed to be furtive in a number of ways. The dial is rendered such that the time can only be read when viewed straight on, making it, to some extent, visible only to the wearer. It is also furtive in the sense that two of its complications — the power reserve and moon phase display — are hidden on the reverse and appears as a time-only watch. Finally, especially in the production version, it is furtive in a more ironic way.

Despite its all-black appearance, which is typically associated with lightweight materials like ceramic, or titanium and steel that have been black-coated, the watch has a surprising heft on the wrist. This is because its case and bracelet are made from tungsten carbide, while the case back, bumper, bezel ring, and crown are made of tantalum. The dial, on the other hand, is executed in high-polish anthracite Grand Feu enamel, a process that took a year and a half of testing and refinement to perfect. Owing to the complexity of its fabrication, production will be limited to no more than 100 pieces.

The tungsten carbide exterior (interspersed with Tantalum elements) is an extremely hard material (approximately 1350 Vickers and 9 on the Mohs scale) that’s obtained by combining carbon and tungsten at high temperatures. Image: Revolution ©

Most notably, the Chronomètre Furtif is powered by the same Calibre 1522 found in the Furtif Bleu. It marks F.P. Journe’s first central seconds movement and includes a power reserve indicator along with a moon phase display on the bridge side. While it shares some of the layout and twin barrel configuration of the Calibre 1304 found in the Chronomètre Souverain, the movement is more elaborate with a total of six bridges, which lend themselves to a higher degree of finishing.

Case and Bracelet in Tungsten Carbide

The case shares the same dimensions as the Furtif Bleu, measuring 42mm in diameter and a remarkably slim 9.5mm in height. Its slimness is all the more striking on the wrist given its diameter which creates somewhat of a visual tension that defies expectation. The bezel, case middle and bracelet are made from tungsten carbide with a black coating.

Tungsten carbide is an ultra-hard composite material, registering around 9 on the Mohs scale, just below diamond. This exceptional hardness not only makes it highly scratch-resistant but also creates an ideal surface for coating adhesion. Because it resists deformation under pressure, coatings like PVD adhere more uniformly and durably, resulting in a finish that’s both visually sharp and long-lasting. In addition to its hardness, tungsten carbide is remarkably dense, about twice the density of steel which gives the watch a satisfying heft and a sense of solidity that belies its slim profile.

F.P.Journe employed the expertise of Les Boîtiers de Genève, a specialist entity owned by FPJ, to rework the entire case middle. They were in charge of the sand-blasted and polished finishes, with the same process applied to the bracelet. Image: Revolution ©

Les Boîtiers de Genève, the case manufacture behind the project, relied on advanced fabrication techniques to meet the demands of this design. As François-Paul Journe explained, he designed the case and collaborated with his manufacture on its internal and external dimensions to accommodate the movement. The engineers and machinists at Les Boîtiers de Genève were then tasked with reengineering the entire case middle and executing both the sandblasted and polished finishes. The bracelet, with its flat three-row link structure, is also crafted entirely from tungsten carbide and represents a significant technical challenge on its own. The result is a piece that is not only conceptually bold but also a triumph of advanced materials engineering.

The tungsten carbide bezel and case middle have a sandblasted finish while the tantalum parts, which consist of the case back and bezel ring, are entirely polished. Polishing tantalum is also a technique that has taken Boîtiers de Genève years to perfect, with the right speed of rotation and the right polishing discs and pastes.

Dial in Mirror-polished Grand Feu Enamel

The most striking and curious aspect of the watch, however, is undoubtedly the dial. It looks unlike any other in watchmaking. Its surface, finished in mirror-polished anthracite Grand Feu enamel over white gold, appears almost blank when viewed straight on. Only when the light hits it at the right angle do the frosted numerals and minute track come into view.

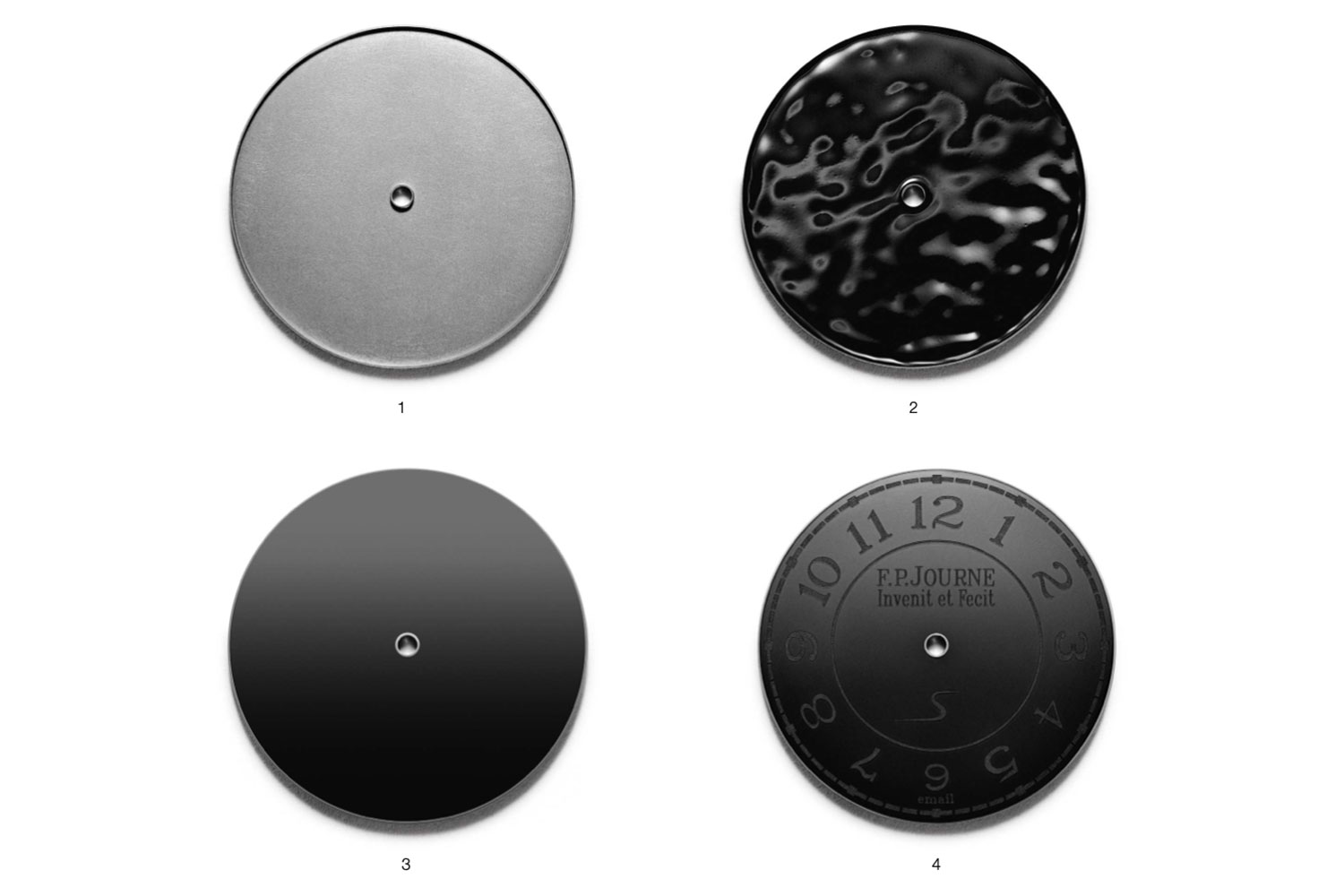

The dial is made by Les Cadraniers de Genève, F.P. Journe’s dedicated dial workshop. It begins as a solid white gold blank, hand-finished with a frosted texture that gives the surface a subtle matte grain to improve adhesion for the enamel layers to come. This is followed by successive layers of powdered enamel, each applied and fired in a kiln heated to over 800°C. The repeated firings gradually build up the rich, anthracite grey surface, a process that requires absolute precision and carries a high risk of failure at every stage. The colour itself took a year to master. Few dials survive the full sequence of firings and inspections.

Those that do are sent to Les Boîtiers de Genève for polishing. Polishing enamel is equally challenging. After multiple high-temperature firings, Grand Feu enamel tends to exhibit a subtle dimpled or orange-peel texture, a natural result of the melting and cooling process. While this texture is expected, it must be carefully leveled and smoothed out during polishing to achieve a uniform, mirror-like finish. Thereafter, they are laser-engraved to create the numerals and minute track. The process selectively removes the top layer of enamel, revealing the underlying frosted texture of the gold beneath. The result is a set of markings that are nearly invisible unless caught by light. The hands, shaped like elongated teardrops, are matte rhodium-plated, which matches the matte numerals and markings. Only the slim white seconds hand offers contrast, sweeping a clear path across the subdued display. This serves as a fitting emphasis, as it is the only central seconds movement in Journe’s catalogue.

A process to creating the dial, as explained by F.P.Journe: 1. Preparation: white Gold dial with a hand-finished surface before enamel application 2. Enamelling: successive applications and firings of vitrified enamel at high temperatures (800°C ⁄ 1472°F) 3. Polishing: mirror-polishing for a smooth and deep surface 4. Matte finishing: laser-frosted numbers, logo and track for a stealth effect

When all is said and done, the Chronomètre Furtif is the only serially produced F.P. Journe watch with a full Grand Feu enamel dial. Previously, enamel was only used for the sub-dials such as those in the Tourbillon Souverain Vertical, which is rendered in champlevé enamel.

The First Central Seconds Movement from F.P. Journe

The Calibre 1522 inside the Chronomètre Furtif marks the first F.P. Journe movement to feature central seconds. There are two ways to achieve central seconds, either indirectly, using an auxiliary gear train driven by the fourth wheel positioned at six o’clock, or directly, by placing the fourth wheel at the center of the movement. Unsurprisingly, given Journe’s emphasis on slimness and mechanical efficiency, the latter solution is used here, allowing the seconds hand to be driven directly without adding unnecessary height or load to the movement.

Despite its apparent simplicity, the movement is smartly constructed. It retains the twin parallel barrels from the Calibre 1304 found in the Chronomètre Souverain, a configuration used to achieve higher and more stable torque which greatly improves chronometry rather than to extend power reserve.

The gear train extends across a wider main plate to accommodate its new functions. The power reserve and a moon phase display are tucked along the periphery of the movement and their additions result in a total of six bridges with the third and fourth wheels along the escape wheel supported by two individual bridges, while the free-sprung balance is supported by a full traversing bridge for stability. The gold bridges are finished with Geneva stripes along with polished bevels along their edges while the main plate is decorated with barleycorn guilloché.

The free-sprung balance with four gold inertia weights is supported by a full balance bridge. Image: Revolution ©

All in all, this is a highly unconventional sports watch and an equally unconventional F.P. Journe. It defies expectations on several fronts from the use of industrially demanding materials like tungsten carbide and tantalum, the highly complex mirror-polished Grand Feu enamel dial that conceals more than it reveals, and a movement that is elaborate and refined well beyond what is typical for a sports watch. It challenges the typical language of sports watches, and in doing so, expands the vocabulary of F.P. Journe itself.

Tech Specs: F.P. Journe Chronomètre Furtif

Reference: Ref. CF

Movement: Manual-winding 1522; 56-hour power reserve

Functions: Hours and minutes; central seconds; (back) moon phase; power reserve indicator

Case: 42mm × 9.5mm; tungsten carbide; caseback, bumper, bezel ring and crown in tantalum

Dial: Mirror-polished anthracite gray Grand Feu enamel on white gold enamelled guilloche

Strap: Tungsten Carbide bracelet with titanium folding clasp and polished Tantalum cap

Availability: Limited production

Price: CHF 85,000 (excl. taxes)

F.P. Journe