A Closer Look: Bulgari Octo Finissimo Ultra Tourbillon

News

A Closer Look: Bulgari Octo Finissimo Ultra Tourbillon

At Watches & Wonders last year, Piaget unveiled the AUC Tourbillon, setting a record for the world’s thinnest tourbillon at just 2mm thick. But before that concept watch even reached production, Bulgari has already reclaimed the title. The Bulgari Octo Finissimo Ultra Tourbillon measures a mere 1.85mm thin, and its bracelet, just 1.5mm. It’s astonishing, though hardly unexpected, given Bulgari already achieved an extreme blueprint with the 1.7mm-thin Octo Finissimo Ultra COSC.

While records are increasingly short-lived, ultra-thin watchmaking, especially at such extremes and in a tourbillon watch, is a complication in its own right and always worth unpacking. Wherever you stand on wearing a two-dimensional watch, the underlying technical achievement remains objectively impressive, and it’s fascinating to see just how far its construction can drift from conventional watches and even conventional ultra-thin watches.

As with the time-only Ultra, the Octo Finissimo Ultra Tourbillon was conceived in partnership with complications specialist Concepto. It retains the same diameter as the time-only Ultra, which is 40mm but has managed to incorporate a tourbillon by restoring the hour and minutes hands into a conventional co-axial display. In the Ultra, the motion works are dispersed laterally to drive the hour and minute hands on the same plane. However, it’s been reinstated here to make lateral room for the tourbillon.

Due to the additional torque needed to drive the cage, the new Calibre BVF 900 has a 42-hour power reserve (compared to 50 in the time-only Ultra) while retaining the same beat rate of 28,800vph. This tourbillon watch employs the same basic strategy, to suppress all components onto the same plane and use the case back as the base plate. The case back, like that of the Ultra, is made from tungsten carbide for rigidity, while the case band, bezel, and bracelet are in titanium. Notably, the case back has cutouts that offer a view of several components — a rarity, as ultra-thin watches that rely on the case back to hold movement parts are typically solid. Once the fundamental architecture of a watch is reconfigured, the next challenge is to push the limits of the individual components.

The Ultra Tourbillon features a bezel, case band, and bracelet crafted from microbead-frosted titanium while the base plate/ case back which is inset and attached to the case band is constructed from tungsten carbide. (Revolution©)

Radical Barrel Assembly

One of the things that’s been overlooked in recent record breakers is the construction of the barrel. These go beyond the typical “hanging” or suspended barrel, which is supported only at its base. By removing the upper bridge that would normally hold the top pivot, the movement thickness can be reduced. However, the Piaget AUC and AUC Tourbillon, the Richard Mille UP-01, the Konstantin Chaykin ThinKing, as well as the Bulgari Octo Finissimo Ultra and Ultra Tourbillon all take the concept further with more radical barrel constructions.

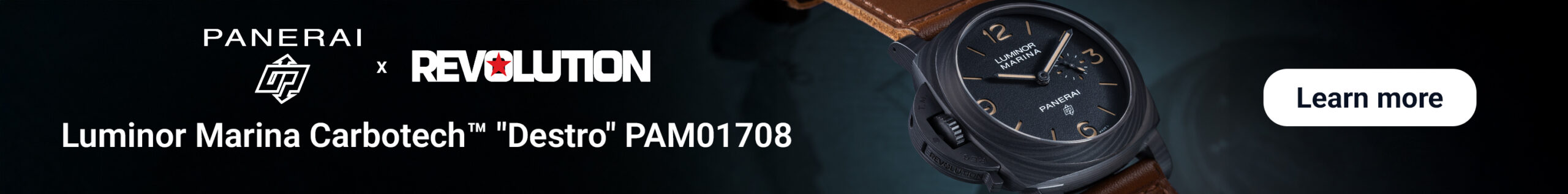

In the Bulgari Octo Finissimo Ultra Tourbillon, the ratchet wheel is directly fixed to the barrel arbour with a screw, enclosing the mainspring without the need for a separate lid. The barrel itself is no longer a closed drum but simply a cylindrical wall with peripheral gear teeth without a base or a lid integral to it. This open barrel is mounted directly on the base plate, which acts as its floor. The arbour is inserted laterally into a precisely machined groove in the base plate and held in place by a bearing surface that prevents axial play once the ratchet is mounted. This not only simplifies the construction but also saves valuable vertical space. It shows how far ultra-thin watchmaking has evolved even from traditional ultra-thin solutions. Since the barrel is unsupported from above, it rotates on tiny rollers set around its periphery, hidden by the overhanging ratchet.

The watch features a compact barrel mounting system that allows the arbour to be inserted laterally into a groove on the base plate. There is no barrel cover; the ratchet itself is directly fixed to the arbour and the barrel drum is simply a peripheral wall with gear teeth (Revolution©)

Despite the improbably slim construction, the watch preserves several traditional elements. A conventional winding click and click spring are tucked into a recess near the center of the base plate. As with the time-only Ultra, winding and setting are performed via two planar crowns on the edge of the case back, eliminating the need for an external tool. A crown wheel with an integrated ratchet and clicks ensures the winding crown rotates in only one direction, preserving the familiar tactile experience in an otherwise radical form factor.

Key Solutions in the Going, Winding and Setting Trains

The mainspring barrel drives the going train and the motion works via separate, non-overlapping paths. This is a classic solution to preserve slimness.

The biggest difference between the Ultra and Ultra Tourbillon is in the going train. Here they are supported only on one side. There are no upper bridges, jewels or bushings. Instead, each wheel runs on ball bearings seated in the base plate. This solution recalls the 1.2mm thick Jean Lassale Calibre 1200 launched in 1976. It was a movement of unusual sophistication but ultimately proved too fragile. In it, the trains for winding and setting were arranged on the same side of the movement. The barrel and the gear train ran on ball bearings with the races installed in the base plate, eliminating the height normally added by bridges and upper jewels. In the Ultra Tourbillon, those same principles – ball-bearing guided wheels, single-sided support and complete lateral integration – are reborn with the benefit of modern materials and manufacturing precision.

An additional wheel is added to the going train to traverse the distance to the cage. The base plate is cut away in that area, leaving a slim skeletonised bridge behind to support the lower pivots, and it carries the ball bearing races.

A look at the “flying” gears in the going train. They are all supported in ball-bearings (Revolution©)

Bulgari Octo Finissimo Ultra Tourbillon Watch (Revolution©)

Bulgari Octo Finissimo Ultra Tourbillon Watch (Revolution©)

Like the Ultra, the Ultra Tourbillon does away with traditional keyless works. Normally, the keyless works comprise components such as the winding stem, winding pinion, clutch, and setting lever, which allow the user to wind the mainspring and set the time through different crown positions. These components occupy both vertical and horizontal space. Here, however, the winding and setting trains are arranged on the same plane, positioned on opposite sides of the watch to minimise thickness.

Bulgari Octo Finissimo Ultra Tourbillon (Revolution©)

Additionally, because the centre wheel and hour wheel are dispersed, and there is no cannon pinion, a new solution is required to allow the hands to be set without disrupting the gear train. In a traditional movement, the cannon pinion functions as a friction clutch. It is friction-fitted onto the centre pinion arbour and rotates with it while the watch runs. When setting the time, the cannon pinion slips over the arbour, allowing the hands to be moved independently without stopping the movement. In the absence of this system, the motion works are instead passively driven via a differential, which allows the time-setting mechanism to be “decoupled” from the gear train when time is being set. The motion works are supported by a circular bridge which has been skeletonised to double as the dial.

Located at 12 o’clock, the differential enables time-setting without interfering with the operation of the wheel train. (Revolution©)

Trimming the Tourbillon

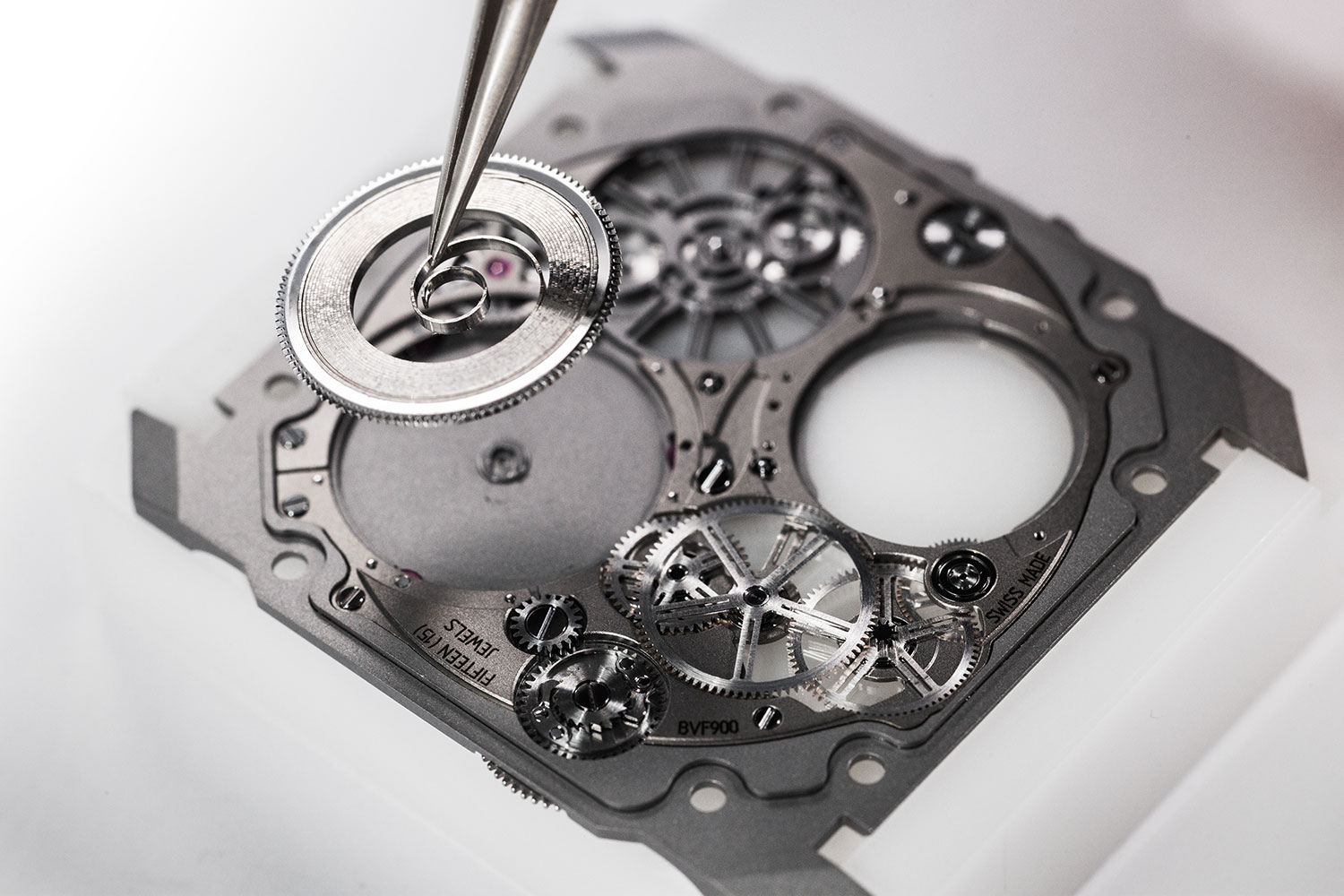

Compared to the Piaget AUC Tourbillon, the Octo Finissimo Ultra Tourbillon has a more classical tourbillon. Similarly, the cage itself consists of a toothed wheel that is driven by the finishing gear on its periphery rather than a pinion beneath the cage. However, the lower cage bridge itself is the toothed wheel which carries the escape wheel.

The lower bridge of the tourbillon cage is a toothed wheel that is driven on its periphery by the last wheel in the going train (Revolution©)

To reduce height further, the fixed tourbillon wheel is a ring with internal teeth. Instead of being mounted beneath the cage, this ring can encircle the cage horizontally, and the escape wheel pinion meshes with it from the inside. These are classic solutions that make for both a slim and airy tourbillon. The cutout in the caseback only emphasises this.

Instead of a regular fixed wheel beneath the cage which only increases thickness, the escape wheel rotates against a fixed peripheral ring with internal teeth (Revolution©)

The tourbillon cage also draws from the solutions introduced in the time-only Ultra. As a recap, the oscillator is modular in the Ultra. It is housed in a cage with compliant arms that offers some give in the event of a shock, and this unit is fixed to the base plate. Here, the tourbillon cage employs similar openworked arms for both upper and lower cage bridges. These arms suspend the pivot bearings, allowing controlled axial movement to absorb shocks, performing the role of a traditional shock absorber but in a vertically compressed architecture. The bridges are flat, the bearing holders on the bridge are minimally dimensioned, and there are no cage pillars. The entire assembly is as flat as structurally possible.

The balance wheel is free-sprung, with gold turnable weights that are recessed into its rim, and is attached to a flat hairspring. The hairspring stud holder integrated directly into one of the arms of the three-armed upper tourbillon bridge, keeping everything on a single level.

Above all, what’s most outstanding about the Ultra Tourbillon is that for all its radical engineering and aggressively minimal dimensions, it is fully realised as a design object. Quite unlike its competitors, the movement architecture is far from feeling clinical or even reductive and manages to evoke a surprising sense of depth in a watch barely thicker than a coin.

Tech Specs

Bvlgari Octo Finissimo Ultra Tourbillon

Reference: Ref. 104313

Movement: Manual-winding BVF 900; 42-hour power reserve; 4Hz or 28,800vph

Functions: Hours and minutes

Case/Dial: 40mm × 1.85mm; titanium; tungsten carbide main plate

Strap: Sandblasted titanium bracelet with integrated folding buckle; 1.5mm thin

Availability: Limited edition of 20 units

Bvlgari