News

Understanding Métiers d’Arts: Guilloché

News

Understanding Métiers d’Arts: Guilloché

Wood sawing in miniature marquetry

The world wars, however, spurred the need for watches that prioritized functionality, durability and precision over craftsmanship. Watch companies were forced to move towards mass production of cheap, durable and reliable military watches. The subsequent Quartz Crisis in the 1970s further cast a shadow, diminishing interest among the younger generation for artistic roles in the industry and resulting in a substantial loss of know-how and skills associated with decorative arts. Yet, with the dawn of the mechanical renaissance, a resurgence unfolded. Manual decoration, including angling and chamfering on movements, experienced a revival alongside artistic crafts like engraving, enameling, guilloché and gem-setting. This revival in craftsmanship aligns with the growing demand for differentiated and more wholly engaging timepieces, ones that display not just fine mechanics but also exceptional aesthetics. In this section, we delve into four primary branches of expertise — guilloché, marquetry, engraving and enameling — and uncover the unique considerations and challenges that define these intricate crafts.

GUILLOCHÉ: The Art of Engine Turning

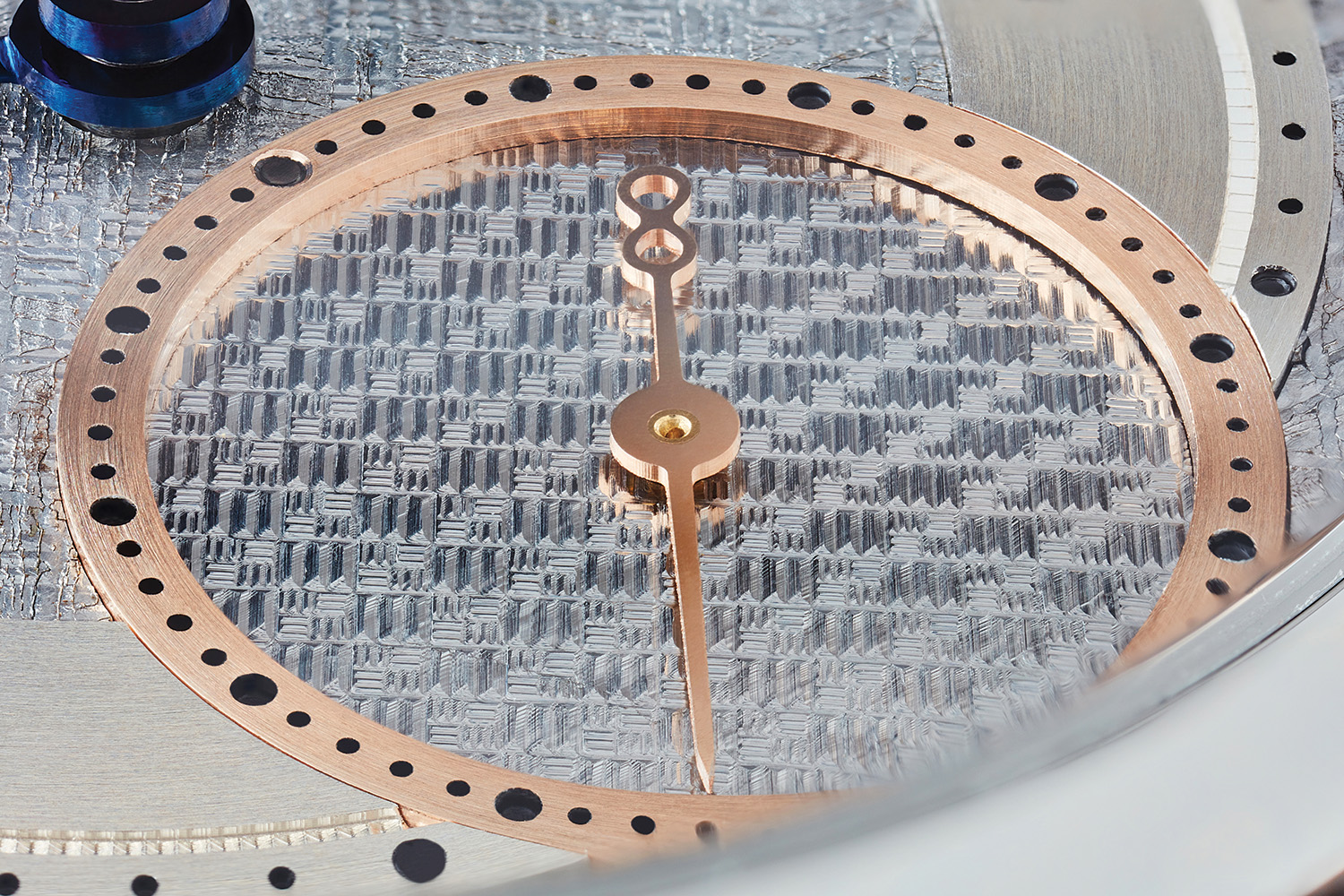

Joshua Shapiro's hallmark Infinity weave pattern

A pivotal figure in preserving and propelling the art forward into the 21st century was the late George Daniels. Aside from being the foremost exponent of mechanical watchmaking, he began to champion engine turning throughout his work from 1969. Notably, in his seminal book, Watchmaking, which would become the horological bible for generations of watchmakers to come, he dedicated over 30 pages to engine turning alone. It offers a comprehensive guide on operating and setting rose and straight-line engines, providing detailed instructions and insights into the application of engine turning techniques on casebacks, flanks and dials. Derek Pratt, a fellow English watchmaker and close friend of Daniels, also demonstrated remarkable expertise as an engine-turner. Some of his finest engine-turned dials bear the name Urban Jürgensen & Sønner.

Today, there has certainly been a resurgence in the practice and demand of engine-turned dials. One of the most prominent independent players in the field is Kari Voutilainen, who has amassed an extensive collection of engine turning machines over the years. In 2022, he acquired Brodbeck Guillochage, the workshop of renowned guillocheur Georges Brodbeck, complete with its array of engine turning machines. He elaborates, “Presently, in our workshop in Chapeau de Napoléon, we have four straightline and four rose engine turning lathes.

Additionally, within our engine turning company, Brodbeck Guillochage, we have more than 20 machines. In total, it adds up to more than 30 machines.” The expansion is to accommodate the increasing demand for engine-turned dials from his dial factory, Comblémine, which manufactures dials for a diverse range of brands in addition to his own clients. Metalem, a dial maker based in the Jura, is another major producer of guilloché dials with an annual output of around 400,000 dials, including enamel, gem-set and engraved dials, with clients spanning from Audemars Piguet to Philippe Dufour.

CNC, STAMPING OR HANDMADE?

Machined and stamped guilloché that attempt to replicate the effect of true engine turning have become prevalent in watchmaking today. It is increasingly difficult to distinguish between them yet it remains possible. Kari Voutilainen explains, “Handcrafted engine turning involves cutting metal using a tool, which results in a sharp surface, with sharp grooves at the bottom. In contrast, CNC machining utilizes a tool that is turning, leaving distinct milling marks, while stamping involves material deformation which doesn’t produce a sharp surface.”

Shapiro's highly incricate Infinity weave pattern is made using a straight-line engine with a specially made pattern bar

Master Cheng highlights the inherent difference between the cutters, “The rose engine cutter is angled at different degrees, such as 90, 100, 110 or 120 degrees. The method of carving is a method of pressing in, cutting and removing the excess. The product will have a shimmery texture.” He explains, “CNC tools are also able to be positioned at various angles. However, the tip of the CNC tool has a slight bevel to aid in the cutting process. The bevel aids in downward cutting. Without it, the tip could break when pressure is applied.” Robin Tallendier, founder of Atelier Wen, emphasizes the limitations of stamped guilloché, “Stamped dials lack depth, crispness and volume. They appear dull and flat. However, it is worth noting that even though they are less common, there are some very well done stamped dials out there. One just needs to look at what Patek Philippe does, for instance, to get a sense of how good stamped dials can be.”

“The cutting tool of the rose engine will leave a continuous horizontal striation, which is not present on a stamped dial,” Tallendier adds. As for CNC machined dials, Tallendier classifies them into two distinct categories, “The first type is made using a drill that is milling and the second is made using a drill that is ‘turning.’ The first one will not have the aforementioned grooves in the ridges, and moreover, it will lack a significant amount of depth and relief compared to handmade guilloché. For the second one, the groove will be present and the depth will be similar to a true handmade guilloché dial.”

To discern the finest CNC machined guilloché from authentically handcrafted guilloché, Tallendier explains that it comes down to the trust placed in the craftsman and the level of perfection. He notes, “If the dial appears clinically perfect, it is more likely to have been crafted by a machine.”

Shapiro adds, “If a company is actively bragging about and showing off their hand skills, it is a good indicator.” He cautions against potential smoke and mirrors when companies suddenly pull out a rose engine machine from storage for the media or boutiques, suggesting the need to look deeper and ask questions amid such presentations. As a general rule, Voutilainen explains, “When patterns are large and rough, they can be done with CNC, but when it gets small and fine, it can only be made by hand.”

HOW IS GUILLOCHÉ MADE BY HAND?

There are numerous operations involved in engine turning, demanding years-long cultivation of very specific skills. According to Roger Smith, “The most challenging aspect of the craft lies in possessing a complete understanding of the machine. Work holding and preparation of the cutting tools are crucial to success, and this can only come with experience.” Joshua Shapiro asserts, “There are so many variables in engine turning. The engraving tool needs to be mirror polished and sharp, the rosettes or pattern bars that the pattern guides off needs to be mathematically and functionally flawless, the guillocheur needs to keep complete concentration with cutting and indexing the machine correctly, and lastly being exceptionally humble and open-minded to correct errors and mistakes.”

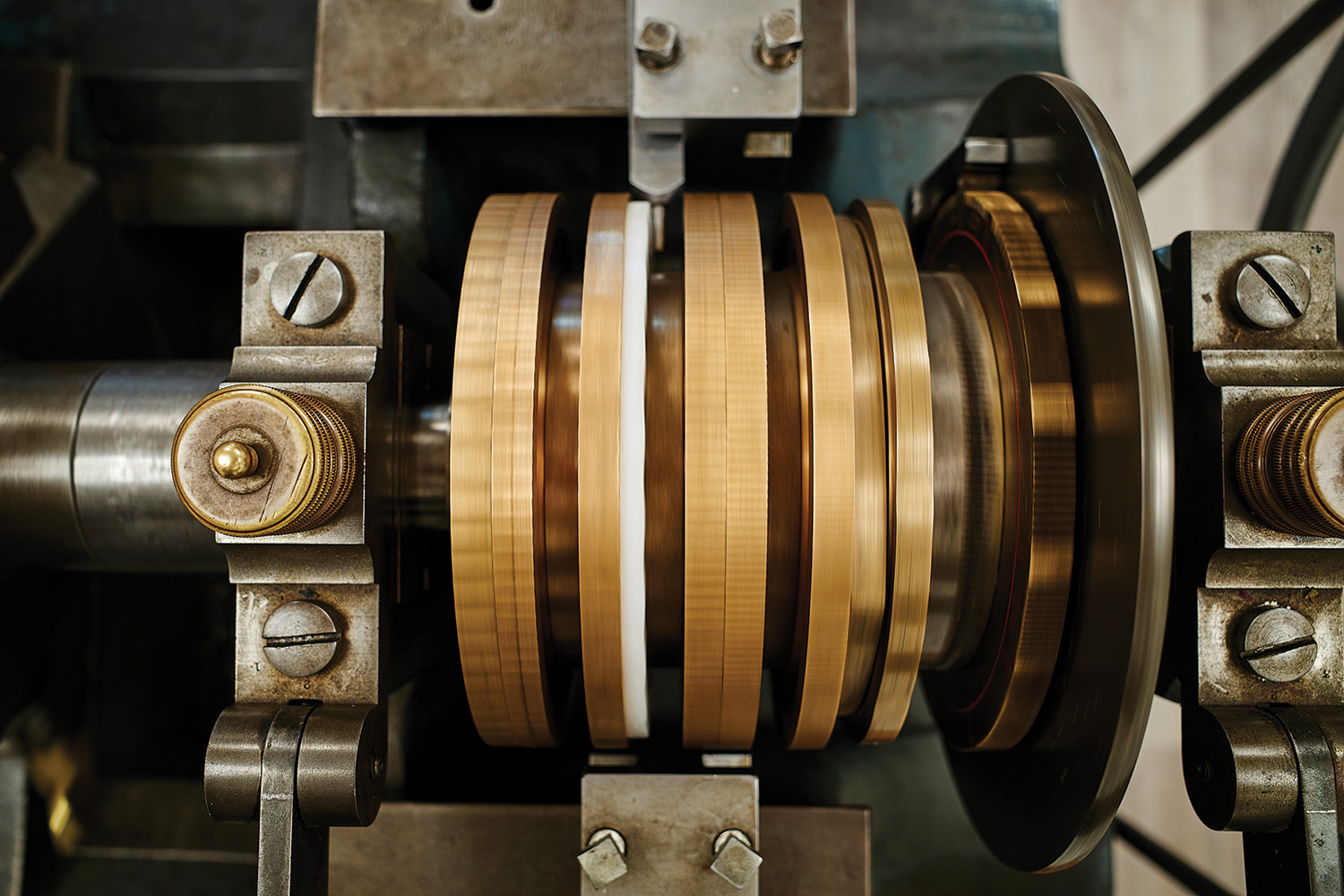

A rose engine consists of several key components, including the main frame, spindle, headstock and a rosette. The process begins with securing the workpiece onto the spindle of the rose engine. The workpiece is often attached to a chuck. At the heart of the rose engine is the rosette, a disk with notches that acts somewhat like a cam. The arrangement, shape and number of notches on the rosette determine the complexity and nature of the resulting pattern. Each notch corresponds to a specific point in the pattern, and as the rosette rotates, the notches are sampled by a feeler known as the touch piece which will dictate the rotation of the workpiece.

The rosettes at the heart of a rose engine (Image: J.N. Shapiro)

The cutter is positioned within a slide, supported in a slide rest with a traverse screw that allows controlled lateral movement of the slide. The depth of the cut is controlled by a rubber, adjusted by a screw. Throughout the process of cutting, manual pressure is constantly applied to the slide, which holds the cutter. Simultaneously, the spindle, responsible for the rotation of the workpiece, is manually controlled with a crank. This consistent dual engagement underscores the incredibly manual nature of the craft, demanding the turner’s coordinated use of both hands.

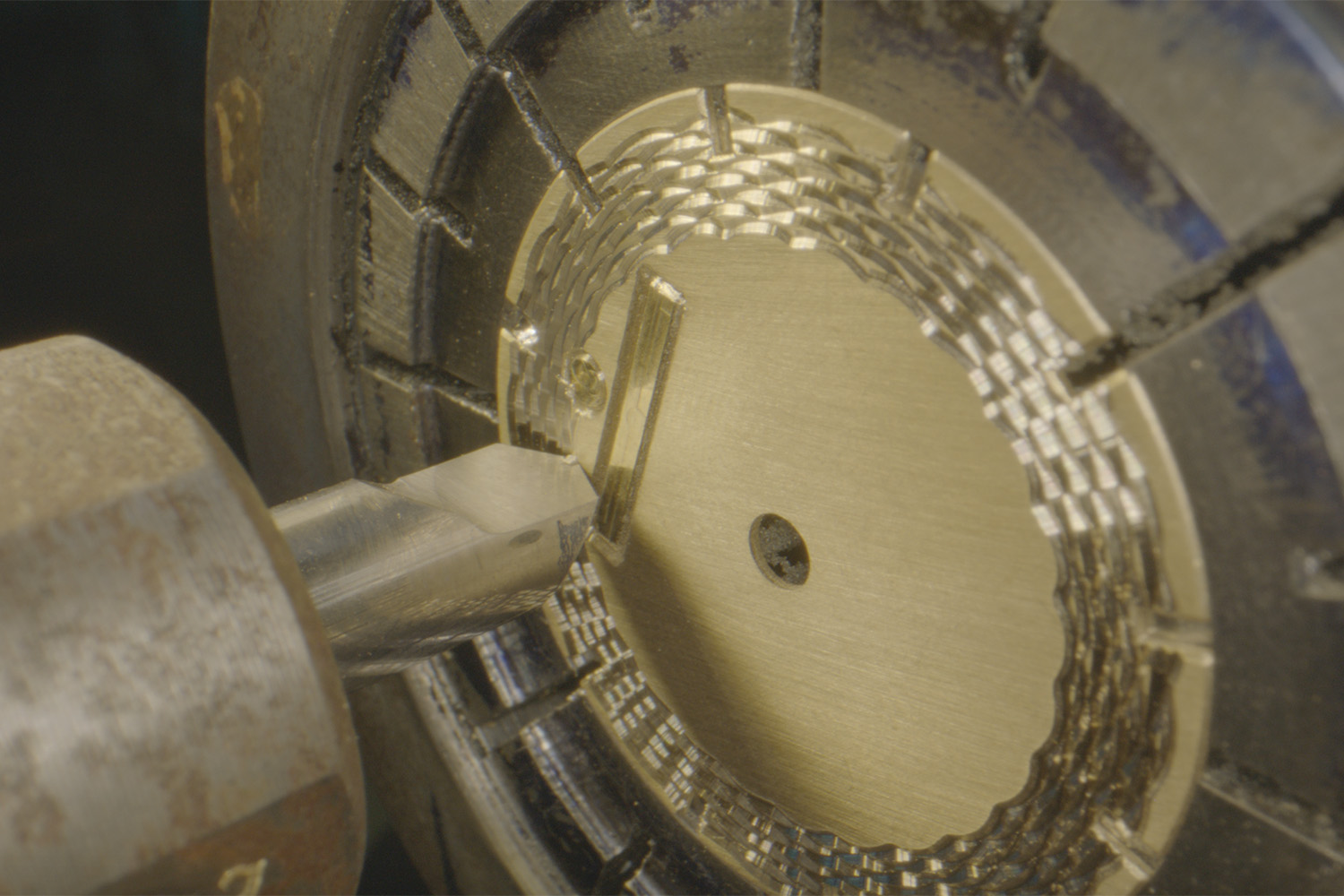

In his book, Watchmaking, Daniels notes, “A constant pressure on the slide is by far the most difficult skill to acquire in engine turning and upon it depends the whole visual quality of the work.” This is because it determines the depth and uniformity of the engraved lines or patterns. If the pressure varies during the process, it can lead to irregularities in the design. Master Cheng stresses that fine and precise guilloché work hinges not only on the guilloché master’s familiarity with the lathe, but also on the sharpness and angles of the cutter so tool craftsmanship is crucial. Rose engines are used to produce circular lines ranging from simple geometric designs to intricate floral or spiral patterns. Some rose engines have adaptors to convert the rotatory motion into a straight-line motion. In a straightline engine, the workpiece is fixed to a nose piece that is carried by a plate. Instead of rosettes, patterned bars are used in a straight-line engine. The plate is attached to a touch piece that samples a patterned bar, which will dictate the horizontal and vertical sliding motion of the workpiece. The slide rest for the cutter, on the other hand, is identical to that of a rose engine.

The fish scale pattern on an Atelier Wen dial, executed using a rose engine

Complexity is introduced through “phasing,” the process of adjusting or shifting the position of the rosette between cuts. This adjustment is made to create variations or different patterns on the engine-turned surface with the use of the same rosette or patterned bar. On the qualities that must be acquired for engine turning, Smith explains, “First and foremost, you need patience, a willingness to learn and ultimately an understanding of what you are trying to achieve. You also need to have the objectivity to refuse your own work and to keep bettering yourself until you have achieved perfection.” The majority of these machines are over a century old and acquiring them is a treasure hunt. Prominent brands and groups eagerly participate in scouring yard sales and auction rooms. During his 2023 lecture at the Horological Society of New York, Voutilainen highlighted the scarcity of engine turning machines in Switzerland. He pointed out that the Swatch Group, regardless of costs, is acquiring the majority of these machines, posing a significant challenge for other industry players attempting to obtain them.

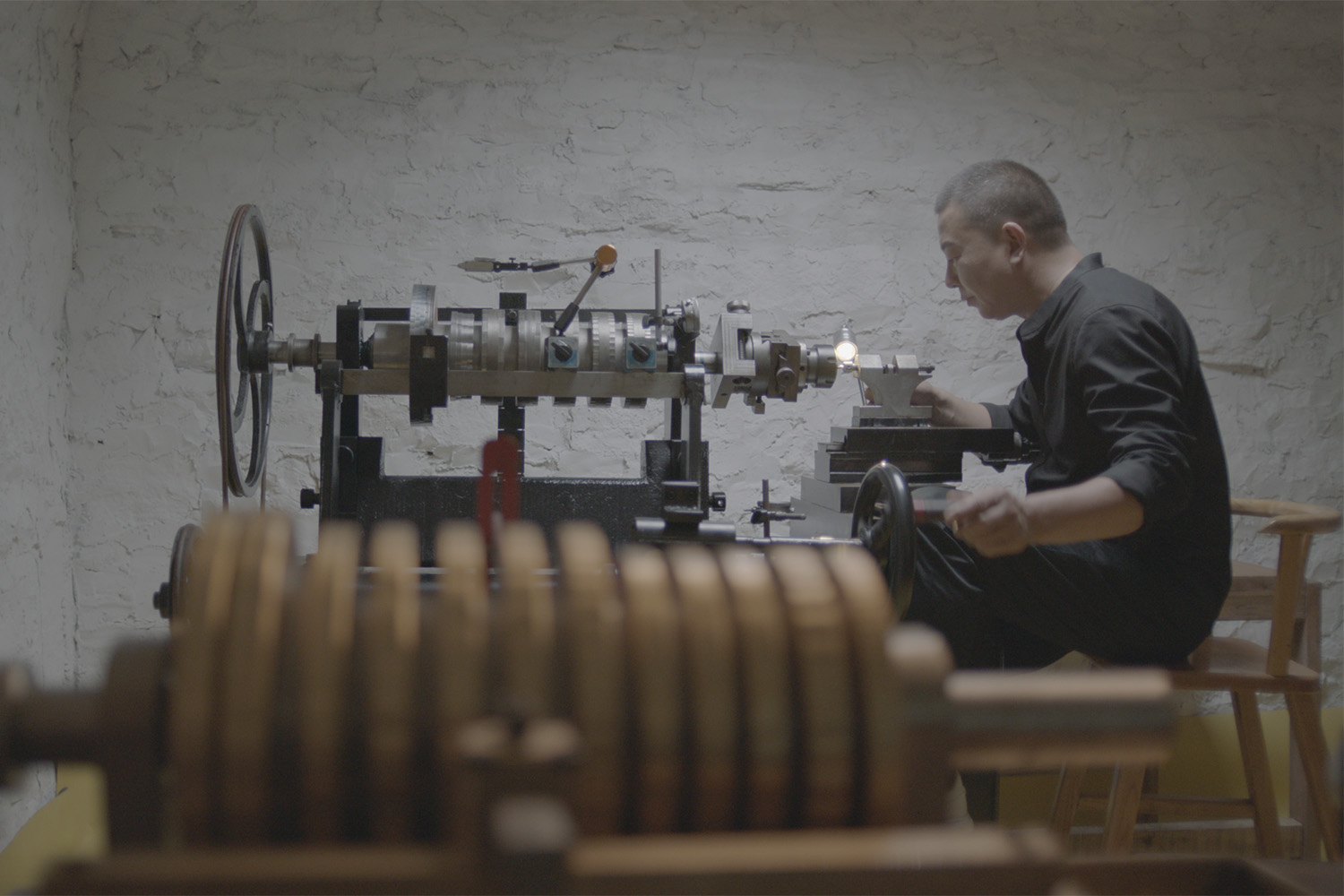

Master Cheng using a rose engine lathe he had built himself

For others far removed from the tradition, the choices often boil down to either acquiring a contemporary engine turning machine or embarking on the challenging task of building one from scratch. In 2014, after seeing guilloché for the first time on a Russian tobacco box, Master Cheng made a life-altering decision to delve into the mastery of engine turning. In the ensuing years, he undertook a remarkable journey to craft his own rose and straight-line engine, despite never having laid eyes on one before. In 2018, after three failed attempts, he finally created his first working machine with over 90 percent of components crafted by hand. By 2021, he had completed his seventh machine, the fourth one in working condition. Cheng opted to construct separate straight-line machines for horizontal and vertical line work. Collectively, these four machines enable him to engrave over 1,000 distinct patterns.

PATTERN VARIETIES

Among the most popular patterns, waves, barleycorn, flinqué and moiré are executed using a rose engine while clous de Paris (hobnail), sunburst and basketweave patterns are crafted using a straight-line engine. “For me, it is always the basketweave pattern that is hardest,” explains Smith. “This is due to the series of repetitive advances that have to be made after each cut. You have to get to a point where your subconscious deals with the pattern of advances so that you can focus on the quality of cut — and this takes practice!”

The Great Britain dial stands as Roger W. Smith's magnum opus, comprising a total of 34 individually engine-turned components

Shapiro concurs, “Straight-line guilloché work, especially the basketweave and beyond, is much more challenging than circular rose engine work.” He details, “A typical pattern found on watches like the Lange 1 or a generic barleycorn requires almost no phasing and maybe 20 to 30 cuts to get to the center. An experienced guillocheur could do this in 30 minutes.” However, he notes, “The moiré gets a bit more complex, and is the most challenging of the rose engine patterns. To do a basketweave pattern for a main dial is about 160 cuts and six phases for a complete unit. This can take many hours.”

Tallendier explains that the complexity of the pattern depends on its density, the number of curves each line has, whether the lines need to intersect and whether there are sub-patterns included in the master pattern. “Our regular dials take about 12 hours of work, but some can take far, far more. Our upcoming silvered dial with you guys takes a staggering 36 hours to make! Some which combine various patterns can take days, if not weeks.” Master Cheng elaborates on the upcoming Revolution limited edition, “Three engine-turners have to dedicate 24 to 28 uninterrupted hours to each dial, and even the slightest error — anything over 0.002mm — is visible to the naked eye.”

The J.N. Shapiro Resurgence comprises 20 individual components. In this instance, Shapiro's distinctive Infinity weave pattern spans four concentric layers, requiring meticulous alignment.

One of the most complex dials ever made by Smith is the dial of the Great Britain, which is made up of numerous individually engine-turned parts that were soldered together. “Creating the dial of the Great Britain was a hugely complex process and it took about three months to develop and master the method,” says Smith. “The multirelief, three-dimensional dial is comprised of some 34 individual parts. The challenge that I had was in attempting to replicate the three colors of the flag by using different engine-turned patterns and heights for the different sectors whilst keeping the subtlety of the dial.” Meanwhile, Shapiro has developed his own pattern known as the Infinity weave, which is a basketweave within a basketweave. This required the development of his own pattern bar. Explaining the intricacy of the process, he notes, “The smaller baskets are interrupted cuts, meaning each miniature basket has to be engine-turned individually without slipping into the larger baskets.”

“There are no lugs on the mid-case during engine turning. Lugs would make it impossible to engine-turn without having ugly interrupted cuts. After we finish the engraving, the recesses for the lugs are milled. The lugs are pulled in by screws. Typically lugs are integral or soldered. With the latter, polishing is needed afterwards to get rid of oxidation, and clean up any excess solder. This is not possible with engine turning on the caseband and the reason we have to use screwed-on lugs. Polishing would destroy the guilloché.”

FINISHING

Finishing guilloché dials is a laborious process that requires great finesse. In particular, for Smith and Shapiro, they employ a process called depletion gilding on silver dials. “The whiteness is achieved by heating the dial with a flame which brings the pure silver oxide to the surface,” Smith explains. “The oxide is then removed and the process is repeated several times until all impurities in the silver have been burnt off and you are left with this pure white texture.” Shapiro adds, “It leaves the dial with a matte frosted appearance; this is also called Breguet frosting, though modern-day Swatch Breguet does something different. Once the surface is oxidized, the dial is plunged into acid to etch away the oxidized impurities. Doing this repeatedly will eventually get a pure layer of silver at the surface that almost glows white.”

In his book, Watchmaking, Daniels notes, “When the surface is evenly white overall, the contrasting patterns of engine turning will not be easily distinguished by the naked eye. To improve the appearance, hold the dial under running water and gently scratch-brush with a soft, brass wire brush. The brushing must be very thoroughly done to brighten the surface equally into the corners.” At Breguet, only solid gold dials are used. As such, to achieve a silvered finish, the dial undergoes a silver coating process after engine turning. Powdered silver is brushed on the plate with circular or linear movements, depending on the type of finish desired.

Subsequently, a thin protective coating is applied to prevent the silver from tarnishing over time. Silvered dials can also be achieved with electroplating, which is a technique employed at Comblémine. Voutilainen elaborates, “We will prepare the dial surface before galvanic treatment. After guillochage, it is slightly worked with humid sandblasting. This creates a fine matte surface without impact. Then in a galvanic bath, rhodium plating turns white.” As for colored dials, various methods such as heating, anodizing, electroplating and lacquering are employed. Shapiro explains, “We will heat-treat zirconium dials to get a dark gray, or anodize titanium to get blue. As for salmon, we use solid rose gold.” He notes, “I try to stay away from paints, lacquers and plating, though I have used them all in the past with much frustration and scrapped dials!”

HOW TO ASSESS GUILLOCHÉ DIALS

According to Voutilainen, Smith and Shapiro, the hallmark of a high quality guilloché dial is its smooth and uniform engine-turned surface. Voutilainen emphasizes, “The surface should be free from burrs in the corners. The engine-turned surface should exhibit a high level of shine immediately after the work is completed, and this shine should persist even after the entire dial is finished. If it is matte, it hides irregularities in the surface.” Smith reinforces this viewpoint, “A tiny blemish will be impossible to hide, so consistency is key.” Shapiro notes that the human eye can detect little variations but cautions against excessive perfection, as it might suggest the use of a CNC machine. He underscores the delicate balance between striving for perfection while still maintaining some humanness in the engraving process.

The moiré guilloché pattern on the Wristcheck x Atelier Wen limited edition

Tallendier adds that he looks at the overall alignment and regularity of the pattern, number of strokes or iterations in the pattern, and therefore, the overall depth effect it manages to create, the cleanliness and the absence of scratches. He also pays attention to the canvas left for the brand name and the logo. “Those areas are particularly challenging to deal with for Master Cheng as they are not guillochéd, meaning that the cutting tool must be withdrawn when reaching the area which significantly increases the likelihood of scratches.” “No dials will end up scoring perfectly on each of those dimensions. The human nature of the work makes this impossible,” he continues. “Despite very well knowing that he will never be able to do a 100 percent perfect dial, Master Cheng, will dedicate absolutely all his energy and time every day to crafting them. I find this hopeless dedication moving.”

Akin to watchmaking itself, where a high degree of manual work elevates the craft, the charm of genuine engine turning work lies in the intimate connection it establishes between the wearer and the artisan who painstakingly crafted it. Much like the difference between viewing a flawless reproduction of a Van Gogh painting in a high quality art book and standing in front of the original masterpiece in a museum — feeling the visceral quality of the brushstrokes — true engine turning imparts a tangible, almost tactile connection to the artisan’s skill, bringing forth an enriched appreciation for the artistry and craftsmanship embedded in every delicate pattern.