A seemingly small development with a remarkable story.

Beyond the conventional emphasis on reference numbers and production years, the history of the Rolex GMT-Master family reveals itself through its continuously changing features. Among these, the bezel insert stands out as a highly recognizable and desired element for collectors. This seemingly straightforward component tells an intriguing story not only through its captivating array of colors but also through the materials used in its construction.

From the early days of Bakelite to the advancements in aluminum and finally, ceramic, the materials used for the bezel insert chronicle the engineering evolution of the GMT-Master. Unlike color schemes that can transcend generations, materials offer a clear-cut narrative – while past color combinations might make a comeback, the materials themselves remain a testament to their era. For example, the “Coke” bezel, characterized by its red and black colorway, stands as a prime case study for the brand’s exploration of bezel materials and colors.

On top of that, the “Coke” bezel has recently stirred significant interest following rumours of its potential return. This renewed excitement is fueled by two notable factors. First, as Rolex nears the 70th anniversary of the GMT-Master II in 2025, enthusiasts naturally anticipate commemorative models, with the “Coke” bezel emerging as a strong contender for a nostalgic nod to the past. Second, and perhaps more importantly, Rolex has recently filed a patent for multicolored zirconia-based ceramic, specifically featuring a two-tone red and black bezel.

The Rolex GMT-Master II 16760 "Fat Lady" with a "Coke" bezel insert. Image by S. Song Watches.

With these developments in mind, now is the opportune moment to explore the history and evolution of the “Coke” bezel. In this article, we’ll explore not only past references featuring this quintessential bezel, but also Rolex’s latest technological advancements in the realm of ceramic materials. While it may seem like a mere ring of ceramic, the “Coke” bezel carries significant historical weight and presents technical challenges, which we’ll uncover through insights provided by the latest patent.

Three eras of the “Coke” bezel: Bakelite, aluminum, and the ceramic dream

The Rolex GMT-Master’s “Coke” bezel, a beloved two-tone red and black combination, has a storied history spanning three material eras. The “Coke” color scheme has been featured on both bakelite and aluminum bezels in the past, and a ceramic iteration remains a tantalizing rumor fueled by a recent patent.

Traditionally, the earliest “Coke” GMT-Master is attributed to the 1982 ref. 16760. This reference marked a turning point for Rolex with the introduction of the GMT-Master II, featuring a groundbreaking complication: the independently adjustable local hour hand.

However, the “Coke” bezel itself has a more surprising origin story. The design actually debuted on the very first GMT-Master, the ref. 6542, way back in the 1950s.

The Bakelite bezel: a luminescent relic

While most ref. 6542 sported the classic blue and red “Pepsi” bezel, a rare variant emerged, the aptly nicknamed “Albino Pan Am Vanilla Coke” GMT-Master.

The unusual Rolex GMT-Master ref. 6542 "Albino Pan Am Vanilla Coke". Image by Jake's Rolex World.

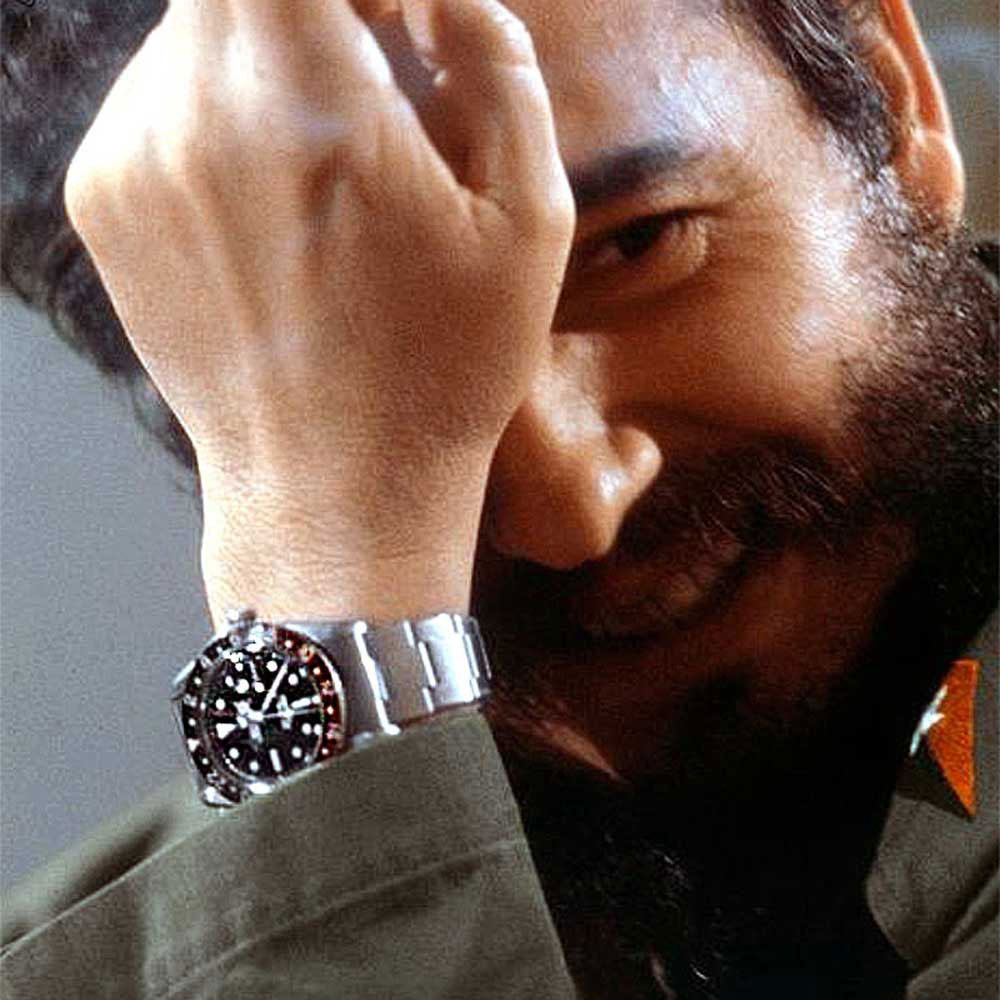

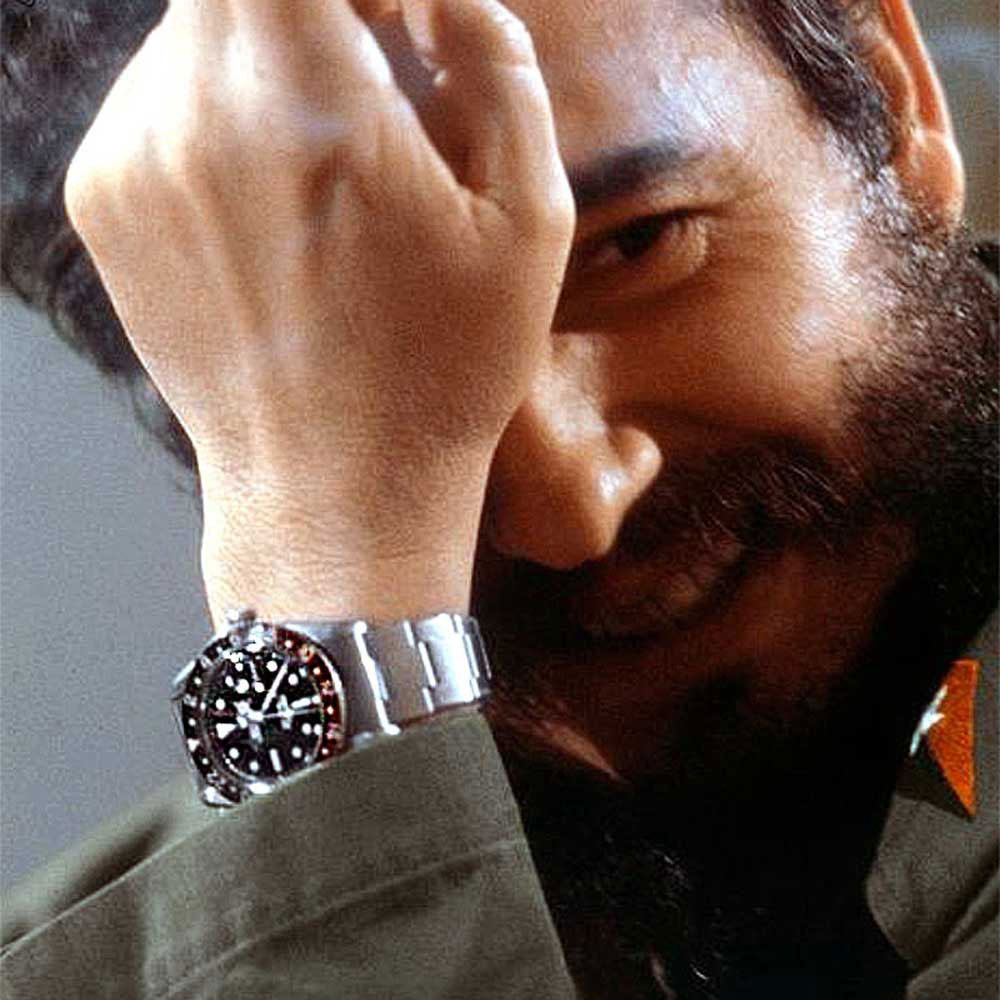

The “Albino Coke” stood out from the crowd with its unique aesthetic: a white dial paired with the red and black Bakelite bezel insert, a departure from the typical offerings for the ref. 6542. Legend suggests Rolex created black-dialed GMT-Masters for Pan Am pilots, while the white-dialed variant with the “Coke” bezel was reserved for executives. Interestingly, photographs also show Fidel Castro wearing a ref. 6542 with a black dial and “Coke” bezel.

Fidel Castro wearing a Rolex GMT-Master ref. 6542 "Coke". Image by Jake's Rolex World.

The first “Coke” bezel insert was indeed made from Bakelite, an early synthetic resin developed in the early 20th century. In fact, it was the world’s first fully synthetic plastic, invented in 1907 by Leo Baekeland, who also coined the term “plastic”. On the ref. 6542, the Bakelite bezel insert featured a thick, clear coating embedding three-dimensional radium numerals. These numerals glowed in the dark, a feature absent from later Rolex GMT-Masters after Bakelite was replaced by aluminum. However, the exact composition of the black and red material beneath the clear Bakelite layer remains unclear, as my research indicates some gaps in understanding.

The "Pepsi" Bakelite bezel insert of the GMT Master Ref. 6542. Image by Jake's Rolex World.

The overly radioactive radium numerals within the Bakelite bezel insert proved problematic. The US Atomic Energy Commission even issued a recall on the ref. 6542. Additionally, the Bakelite’s susceptibility to scratches and cracks presented another issue. In response, Rolex swiftly transitioned away from these materials.

Just four years after the ref. 6542’s introduction, Rolex unveiled the new ref. 1675, featuring an anodized aluminum bezel. While the “Pepsi” aluminum bezel insert became the mainstay for the ref. 1675, “Coke” variants occasionally surfaced. Notably, a 1975 photograph depicts Marlon Brando sporting a ref. 1675 with a “Coke” aluminum bezel insert.

As this photo was taken in 1975, the only GMT-Master references that existed were the ref. 6542 and ref. 1675. This particular example features a crownguard, suggesting it was a ref. 1675 "Coke". Image by Jake's Rolex World.

1982 marked a significant milestone for Rolex with the introduction of the first GMT-Master II. Unlike its predecessor, the GMT-Master, the GMT-Master II boasted an innovative new movement: the cal. 3085. This allowed for the decoupled setting of the 12-hour and 24-hour hands for the first time. Before this advancement, adjusting the local time would also move the 24-hour hand, necessitating the setting of the second timezone by rotating the bezel to align with the 24-hour hand.

The very first Rolex GMT-Master II, the Ref. 16760 "Fat Lady" with a "Coke" bezel insert. Image by Phillips.

The inaugural GMT-Master II, the Ref. 16760, debuted with a “Coke” aluminum bezel insert. Affectionately nicknamed the “Fat Lady” due to its thicker case and movement, the Ref. 16760 remained in production from 1982 to 1988.

Interestingly, the GMT-Master Ref. 16700, introduced in 1988, co-existed with the GMT-Master II until 1999. Like its counterpart, the Ref. 16700 also offered the “Coke” bezel. This simultaneous production of two different generations of models is improbable in today’s Rolex landscape, where meticulous planning and incremental changes define generational updates.

In 1989, Rolex introduced the Ref. 16710 GMT-Master II, the successor to the Ref. 16760. Notably, the steel version of the Ref. 16710 offered a trio of bezel insert options: “Pepsi,” “Coke,” and all-black. This reference remained in production until 2007, marking the last appearance of the “Coke” bezel in a Rolex GMT… until potentially now.

Rolex’s quest for the ceramic “Coke” bezel

In 2005, Rolex commemorated the GMT-Master family’s 50th anniversary with a surprise! The new GMT-Master II ref. 116718LN emerged, boasting a black ceramic bezel insert and a striking green dial. Two years later, the steel version with a black dial, the ref. 116710LN, joined the lineup.

Rolex’s journey with ceramic bezels is fascinating. Examining the chronological order of their ceramic bezel introductions and the raw materials used reveals a relentless pursuit of engineering perfection, which is the typical Rolex’s way.

Simply put, Rolex favors advanced or “technical” ceramics. These differ from traditional ceramics in their formula. Technical ceramics are derived from synthetic powders, allowing for controlled processing and output. This is crucial for Rolex, considering their high production volume and commitment to flawless products. Traditional ceramics, on the other hand, rely on natural materials like kaolin and feldspar. While undeniably beautiful – as evidenced by antique fine china fetching millions at auction – these materials are better suited for art pieces than mass production with precise control.

The ceramic raw material in powder form. Image by Rolex.

In Rolex’s own words, these technical ceramics achieve exceptional mechanical, thermal, electrical, biochemical properties, alongside chemical inertness and anti-magnetism. These qualities make them ideal for use in both movement components and exterior parts of timepieces. Their applications extend to the aerospace and medical industries as well.

Within the realm of technical ceramics, two main types exist: alumina-based and zirconia-based. From the outset, Rolex has favored zirconia ceramics.

Zirconia is known for its superiority over alumina in specific areas, particularly wear and tear resistance. Zirconia boasts double the density and four times the toughness of alumina. Toughness signifies the material’s ability to absorb energy and deform without cracking, making zirconia-based ceramic less brittle. Additionally, zirconia offers superior resistance in highly corrosive environments, exceeding the needs of everyday wear but aligning with Rolex’s commitment to exceptional quality. Finally, zirconia allows for a higher surface finish.

Coloring zirconia-based ceramic, however, presents a significant hurdle for Rolex, as evidenced by their patent filings. These filings detail the complexity of transforming zirconia’s natural white base into vibrant, multi-colored combinations.

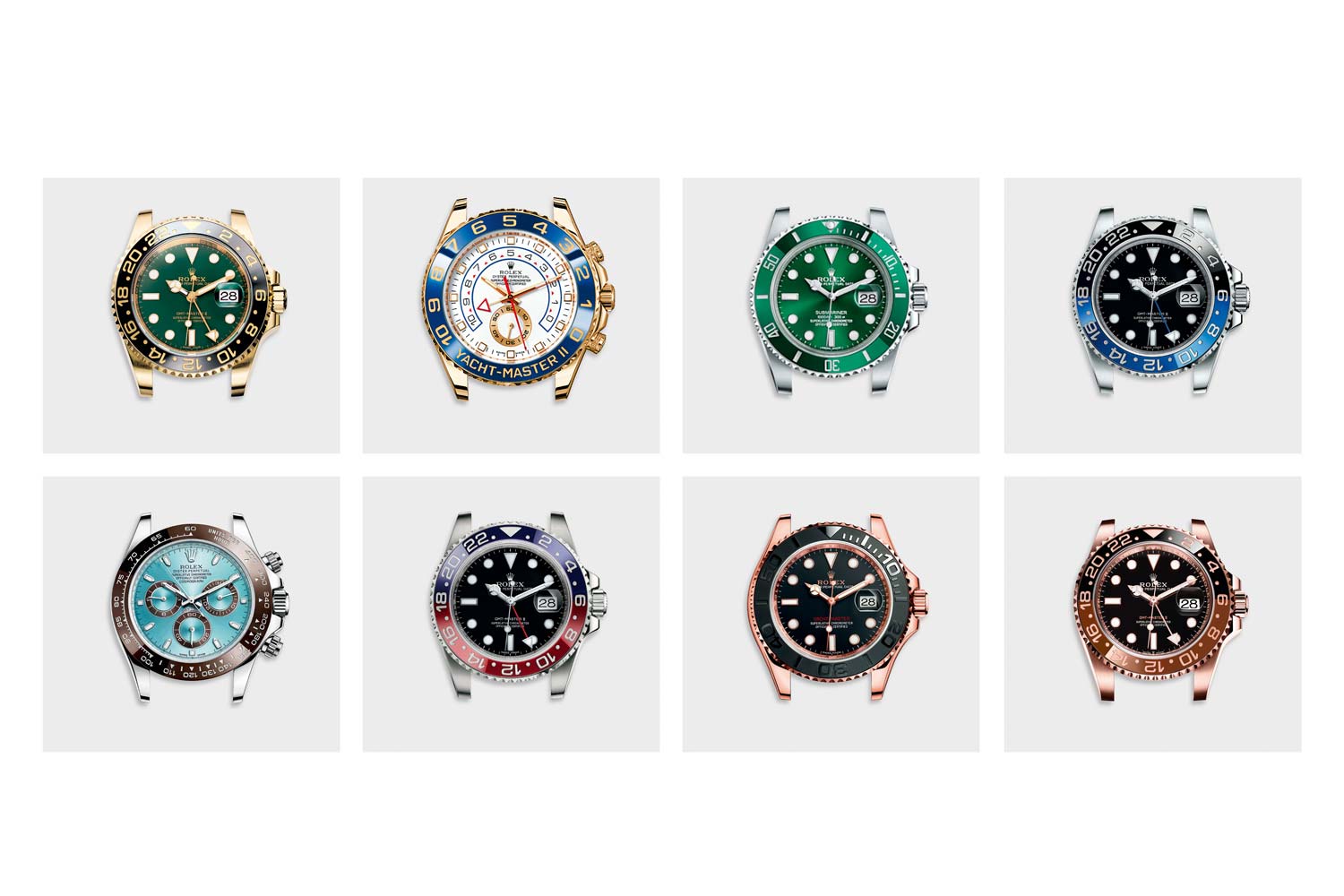

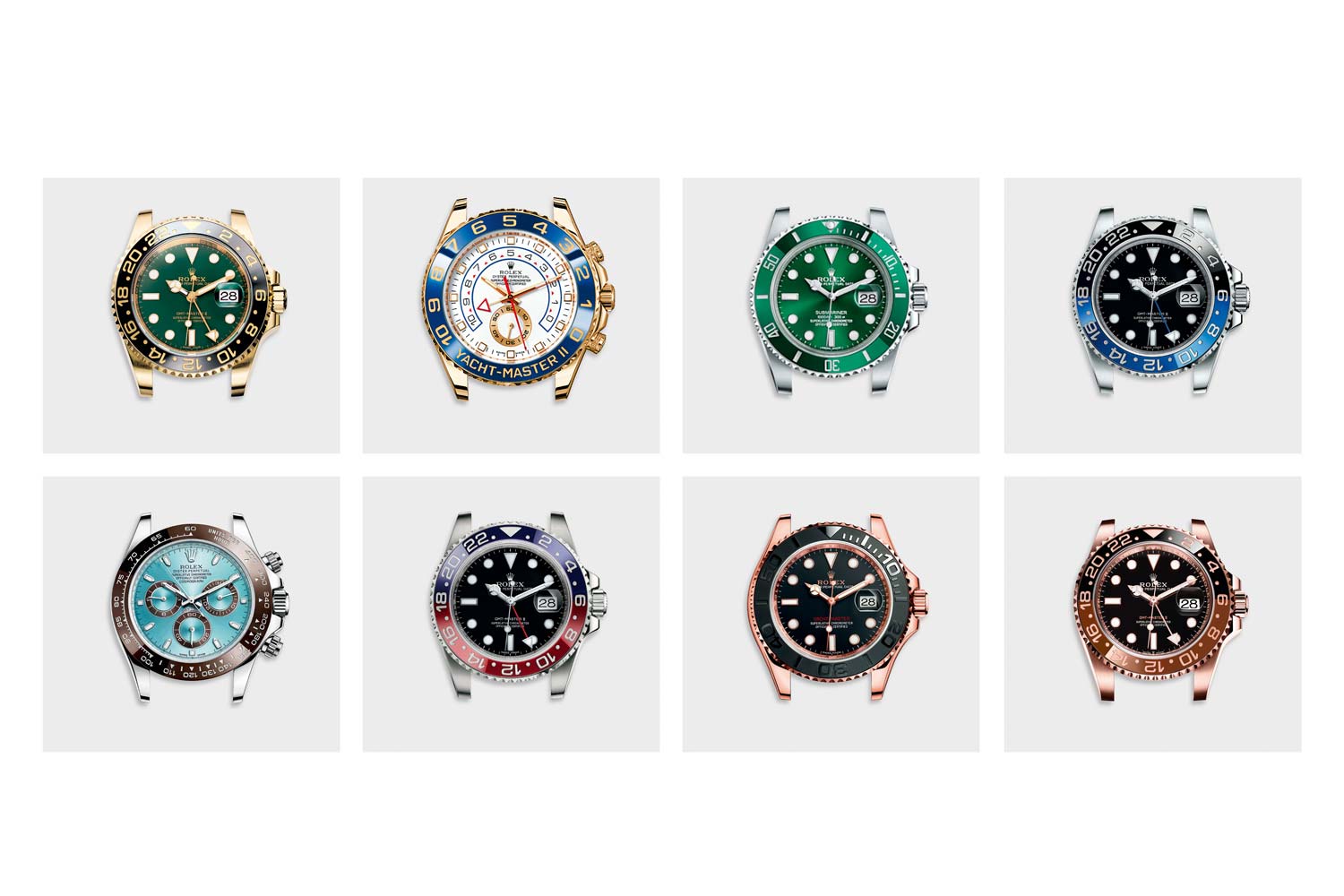

This difficulty is further reflected in the progression of colors seen in their ceramic bezels. Initially, Rolex focused on mastering single colors, like the black bezel introduced on the 2005 GMT-Master II, the blue bezel on the 2007 Yacht-Master II, and the green bezel on the 2010 Submariner.

Rolex watches with Cerachrom bezel inserts. Image by Rolex.

It wasn’t until 2013, eight years after their first ceramic bezel, that they unveiled a two-tone version – the blue and black GMT-Master II “Batman”. The following year marked the introduction of the red and blue “Pepsi” bezel on a white gold GMT-Master II, followed by the brown and black “Root Beer” in 2018. Most recently, in 2022, Rolex debuted the two-tone green and black ceramic bezel on a left-handed GMT Master II, affectionately nicknamed “Sprite”.

The black and blue zirconia-based ceramic bezel insert. Image by Rolex.

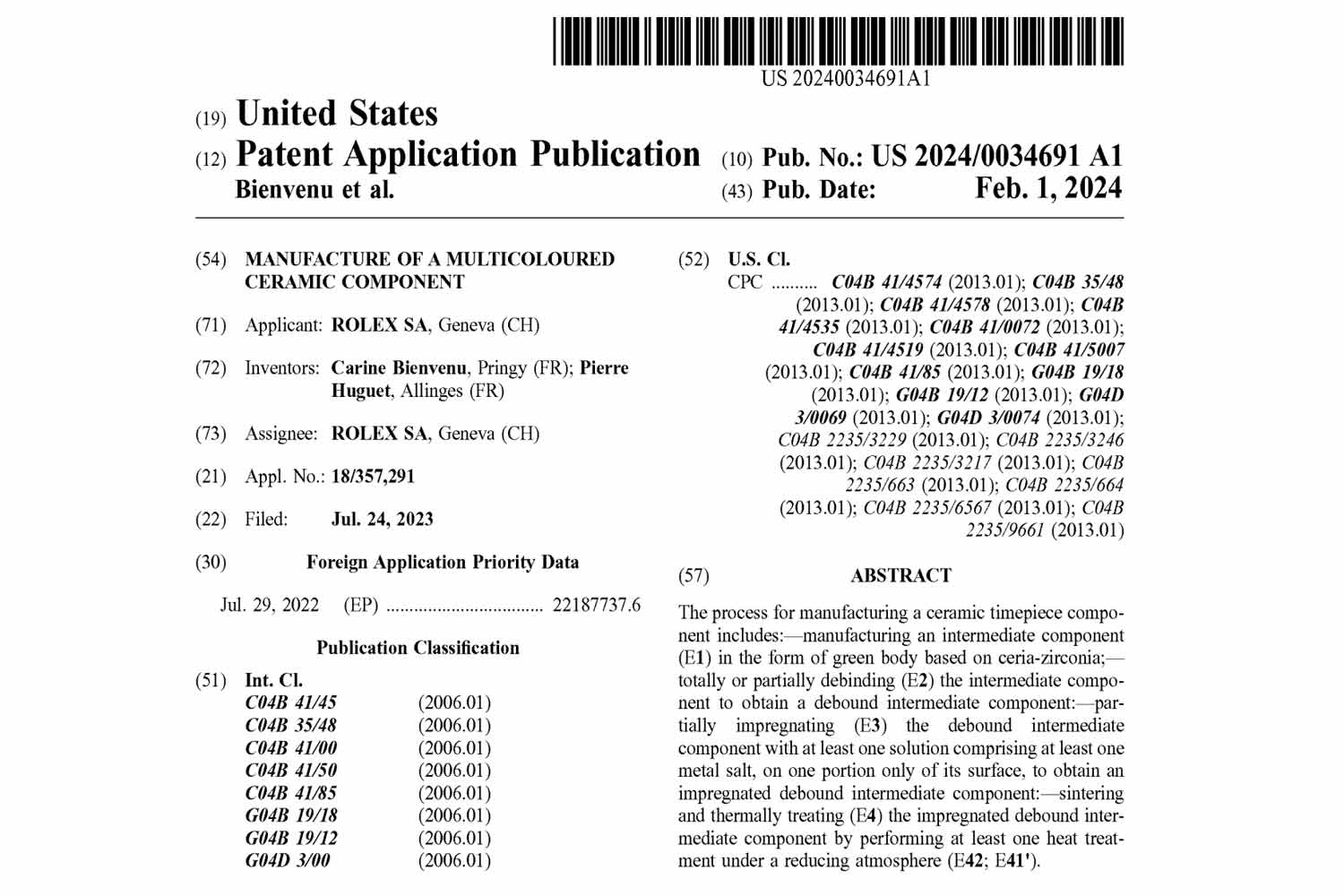

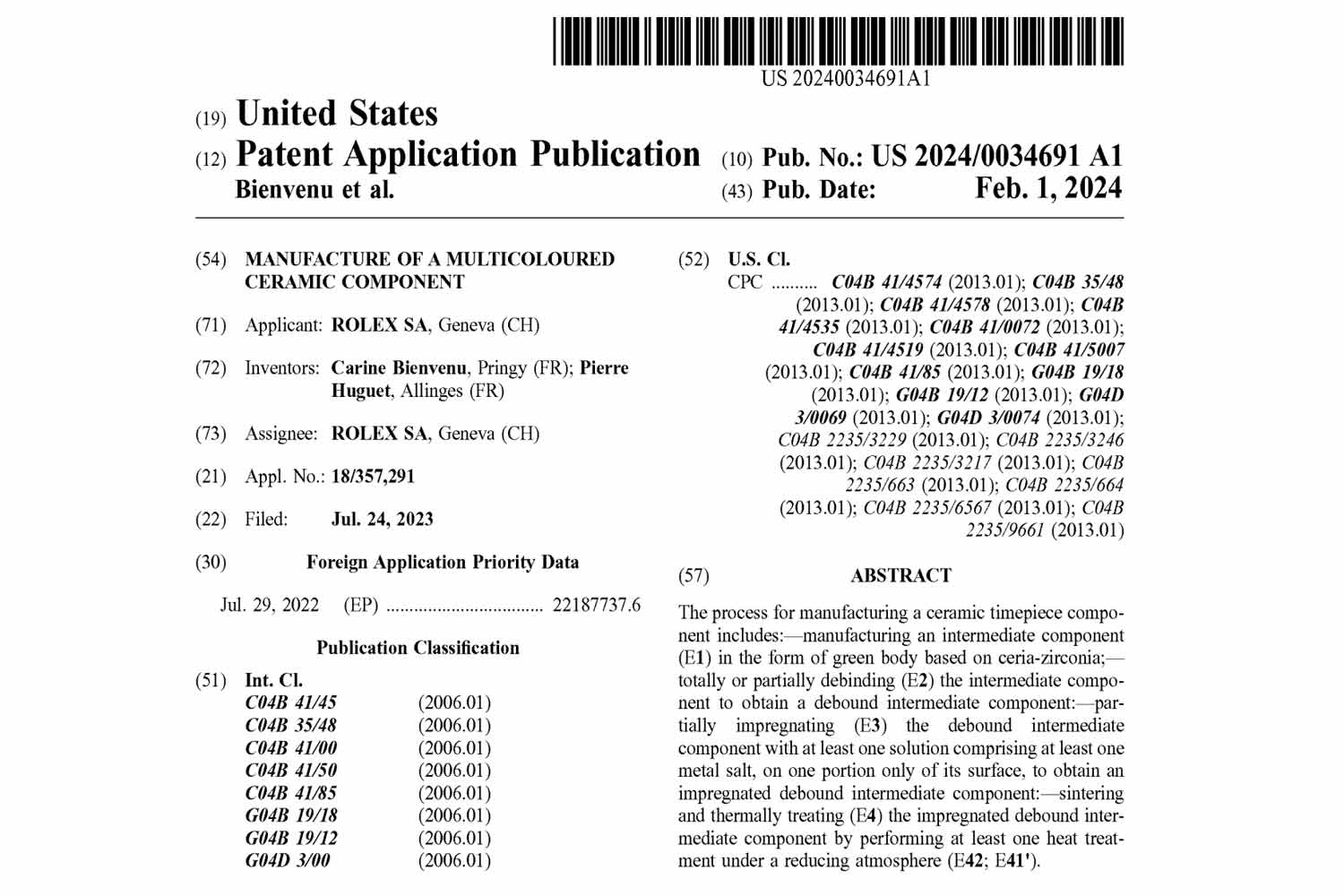

In July 2023, Rolex filed a patent (US2024034691A1, published February 2024) regarding the creation of multi-colored ceramic components. Notably, the patent appears to highlight a breakthrough by Rolex’s engineering team in producing ceramic bezels, particularly the coveted “Coke” bezel made from zirconia-based ceramic (used as the central example).

Rolex's latest patent covers the manufacturing process of a multicolored ceramic component, specifically a two-tone red and black ceria-zirconia based ceramic. Image by Espacenet.

Understanding this patent’s significance requires delving into a key challenge: achieving a red ceramic for Rolex bezels. Despite advocating for zirconia-based ceramic on websites, press releases, and even patents, Rolex has historically used alumina-based ceramic for the “Pepsi” bezel.

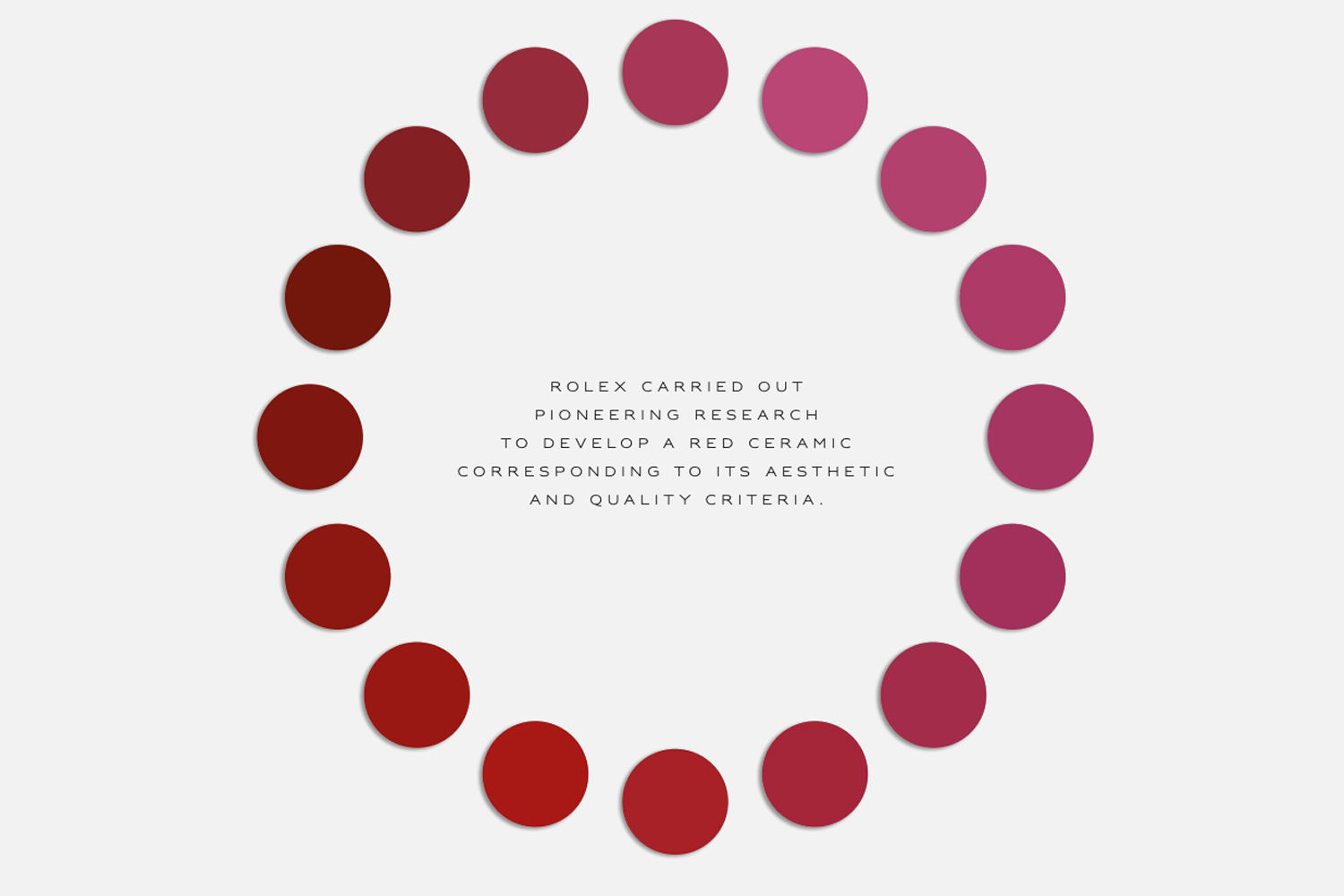

The circle of red. Image by Rolex.

A 2018 press release for the steel GMT-Master II “Pepsi” sheds light on this issue: “Producing a red color required a different approach with regard to the initial ceramic mixture. This is because no stable mineral pigments exist to create a pure red color in zirconia. The brand therefore undertook significant research to develop an alternative using alumina in place of zirconia.”

The only alumina-based ceramic bezel insert in Rolex's lineup so far. Image by Rolex.

In essence, the red alumina-based ceramic bezel has been a sticking point for Rolex, as all their other ceramic bezels utilize zirconia. Finally, this new patent (US2024034691A1) allows them to create a two-tone ceramic bezel with red as one of the colors, using zirconia-based ceramic. The patent specifically emphasizes the “Coke” bezel, highlighting that it’s now “possible to obtain a ceramic with controlled color, allowing for a multi-colored, particularly two-tone, specifically red and black, result.”

In other words, this marks the first successful creation by Rolex of a zirconia ceramic bezel in red, as the brand’s previous red ceramic bezels were all based on alumina.

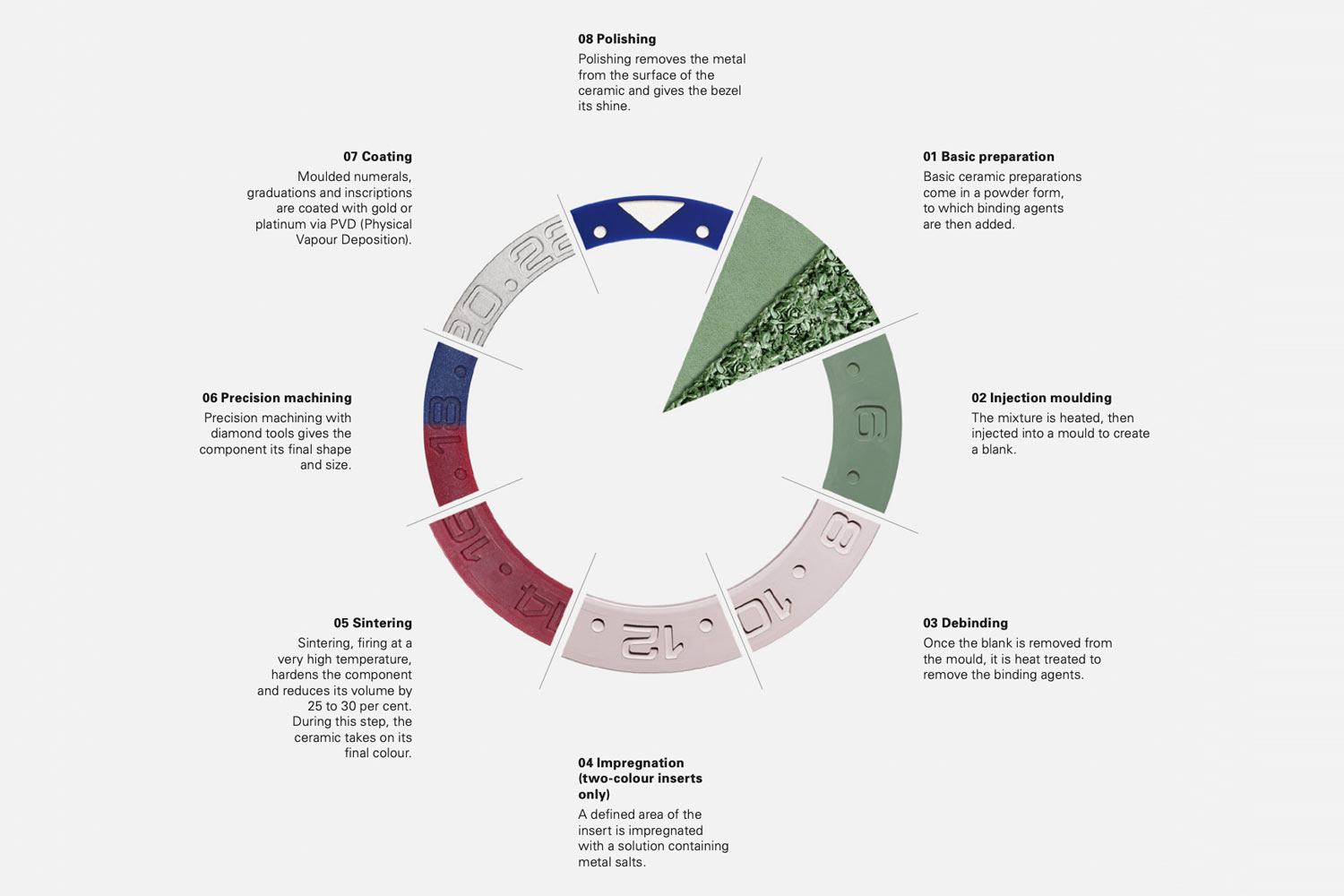

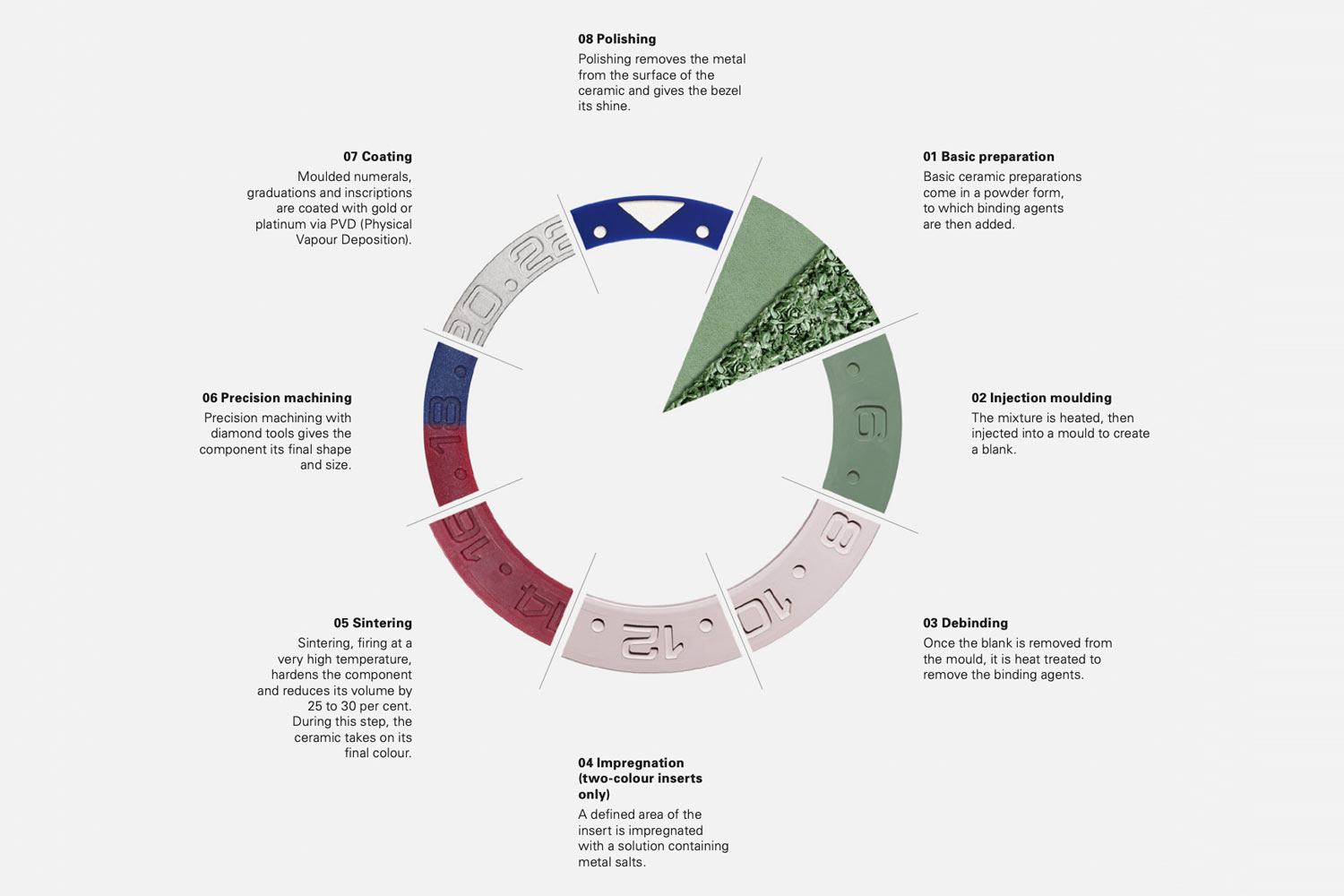

The making of a Rolex Cerachrom

So, how does Rolex achieve those red and black colors on their zirconium ceramic bezels? Let’s delve into the process. Creating a zirconium-based ceramic bezel insert in red and black involves several steps. Let’s break it down:

The making of an alumina-based 'Pepsi' ceramic bezel. Image by Rolex. Note that the zirconia-based 'Coke' bezel undergoes a slightly different process, requiring two sintering processes.

The process can be categorized into three main stages: assembling the raw materials into an initial shape, coloring the ceramic, and the baking and heating process to achieve the desired hues. Each of these stages involves multiple steps, which are depicted in the picture below.

The first step involves preparing the raw materials that form the foundation of the ceramic bezels. Zirconia powder makes up the bulk of the mixture (at least 50%), carefully blended with cerium oxide (3-6%). Rolex emphasizes the importance of cerium oxide, referring to the mixture as “ceria-zirconia” due to its role in achieving the desired red color (explained later). A small amount of alumina (0.1-1%) is then added, as its proportion significantly impacts the final color and opacity. Finally, a binder composed of organic compounds ensures the mixture holds its form.

The preparation of various basic materials for a Cerachrom bezel. Image by Rolex.

After mixing, the ceramic mixture undergoes a crucial stage: shaping. Using techniques like pressing, injection molding, or casting, the mixture is molded into its desired form, including the recess for the numerals. This creates the “green body,” an unfired ceramic piece that retains its shape. Debinding follows, during which heat treatment to at least 750° C for one hour removes some or all of the binder from the “green body”.

Coloring through impregnation

After the initial mix is prepared, the coloring process takes place through a technique called impregnation. This involves covering either half or the entire surface of the unfired ceramic bezel with an aqueous solution of metal salts. This process can be done manually or with the help of inkjet printing.

A black zirconia-based ceramic bezel insert. Image by Rolex.

The specific metal elements within the salt solutions determine the final color after the heating stage. Rolex mentions that these solutions can produce colors like “orange, brown-grey, and advantageously, black.” As an example, they’ve also identified specific metals that contribute to achieving a black ceramic bezel, including copper (Cu), iron (Fe), manganese (Mn), and nickel (Ni).

Heating to achieve the final hue

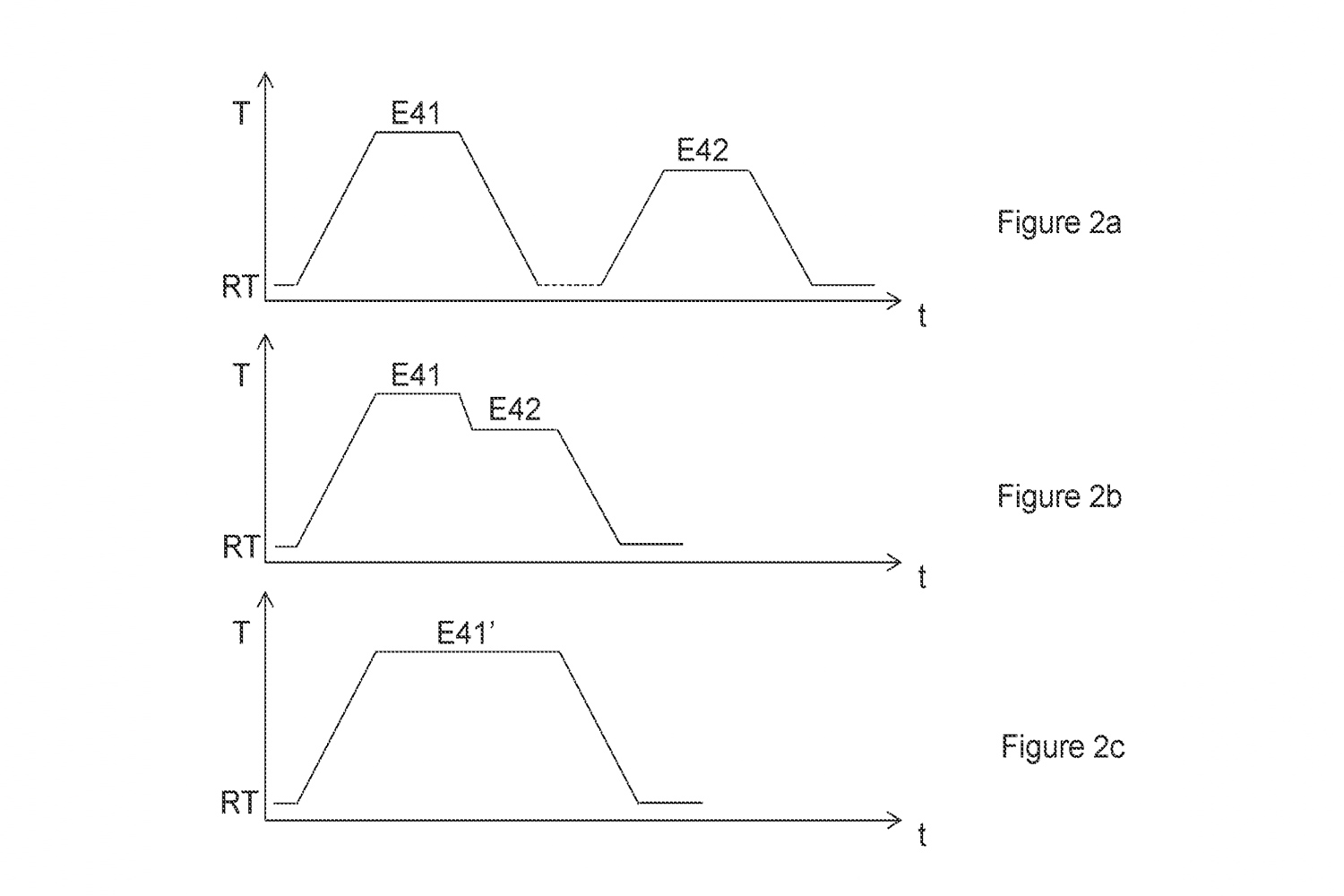

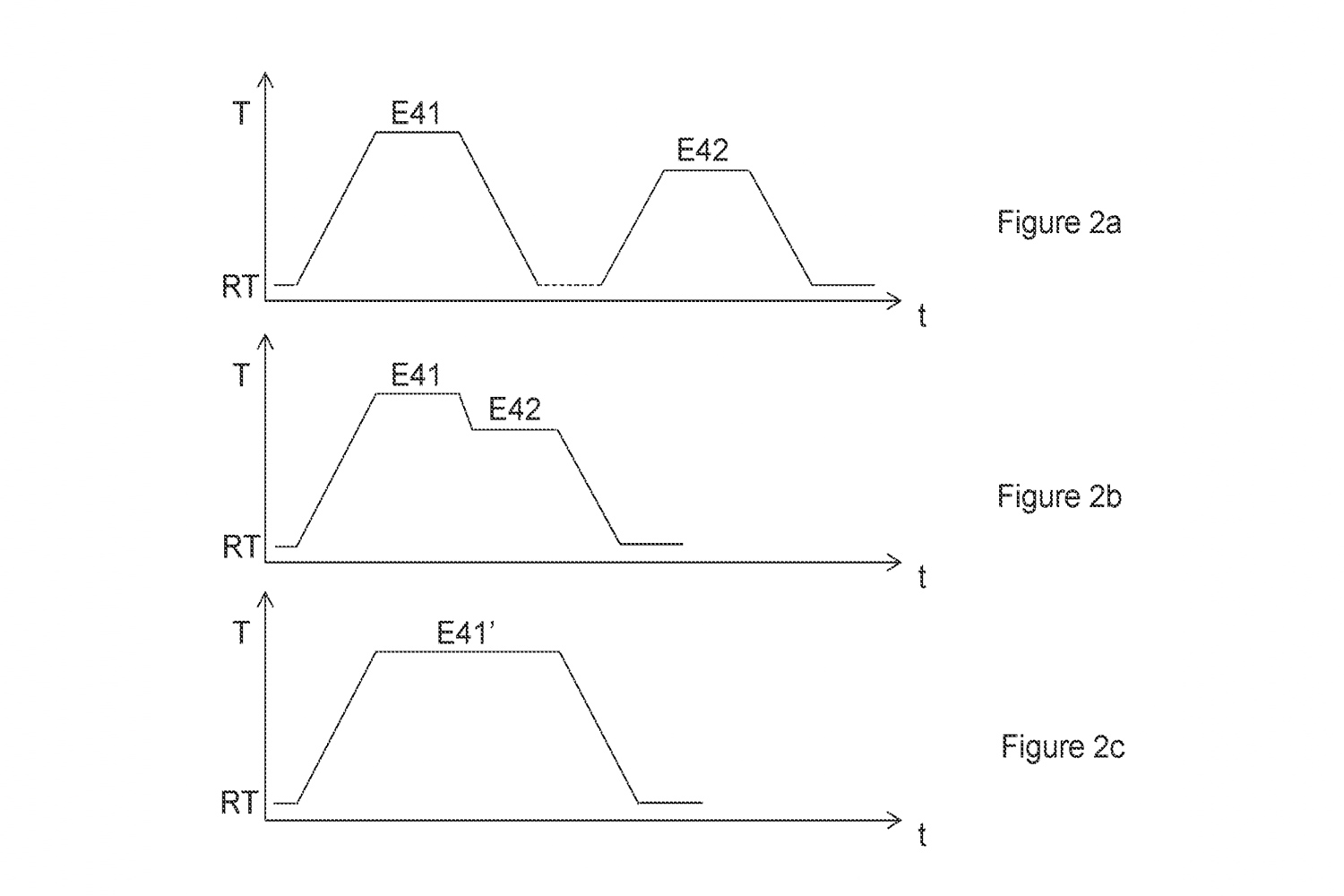

The final stage involves a two-step heating and sintering process. This is where the manipulation of temperature and atmosphere unlocks the vibrant colors within the ceria-zirconia. The first stage, oxidation, takes place in an environment rich in oxygen (like air) at temperatures ranging from 1400°C to 1650°C for at least 30 minutes. After this process, the impregnated and non-impregnated areas will show different (but intermediate) colors. For example, the “Coke” bezel requires a 2-hour thermal hold at 1480°C in air. After this initial oxidizing treatment, the non-impregnated area will appear yellow, while the impregnated half will turn blue (due to cobalt salts).

The two-step sintering process depicted in a temperature versus time graph. E41 denotes oxidizing sintering, while E42 indicates reducing sintering. E41' represents a special case where E41 and E42 are combined into a single step of reductive sintering. Image by Rolex.

The second stage of heating takes place under a reducing atmosphere, where oxygen is deliberately restricted. This crucial step allows for further color modification, particularly on the non-impregnated zones. As Rolex points out in their patent, “the total or partial reduction of cerium oxide enables forming a color ranging from bright red to orange-red on at least one non-impregnated zone.” Returning to the “Coke” bezel example, a further one-hour thermal hold at 1400°C is applied, in a reducing atmosphere composed of hydrogen and argon. A remarkable transformation happens: the non-impregnated ceria-zirconia zone changes from yellow to red, while the previously blue impregnated areas turn black.

Thus, the “Coke” bezel, made from zirconia-based ceramic, is brought to life! Following that, the bezel undergoes sandblasting and PVD coating with platinum for the recessed numeral sections, followed by polishing to achieve a striking surface finish.

A surprising two-tone black and red ceramic bezel on the 2023 Daytona "Le Mans" ref. 126529LN - marking Rolex's inaugural release of a red and black ceramic bezel. Image by Rolex.

Rolex’s journey in engineering colorful ceramic bezel inserts is one marked by perseverance, patience, and innovation. Over the years, the brand has dedicated extensive effort to researching and perfecting the art of ceramic bezel creation, striving to achieve both aesthetic excellence and durability. And now, it appears that their efforts have borne fruit – a breakthrough has been made.

With the making of cerium-zirconia ceramic in two-tone red and black, Rolex has reached a new milestone – it has finally found a way to make red zirconia ceramic! Previously, the brand had produced zirconia-based ceramic in various colors except red, and utilized alumina-based ceramic for two-tone inserts involving red. However, with the latest advancement, Rolex can bid farewell to the only alumina-based ceramic in its collection, completing the transition to the stronger, zirconia-based ceramic for all colors.