In the second instalment of this series, we delve into the ongoing design phase, shedding light on the progress made and hurdles confronted in refining the complex movement of the Sartory Billard SB08 Jump Hour and Minutes with Tourbillon.

Having begun on a journey to create a highly complex jump hour and minutes tourbillon watch a year ago, Sartory Billard is currently in the advanced stages of the design process, where both the dial and movement are almost finalised.

To recap in brief, after designing an array of remarkably successful, fully customisable time-only watches, namely the automatic SB04, the hand-wound SB05, and the SB07 sports watch, Armand Billard decided it was time to venture into the realm of complications. At the tail end of last year, the brand unveiled its first tourbillon watch – the

SB06 Flying Tourbillon, which was a project that stemmed from a request by Cronotempvs, a private collector’s club in Spain. For the SB08, Armand decided on a digital hours and minutes complication, a choice intended to liberate a considerable expanse of the dial for personalized customization.

Watches with jumping displays, as it is, present significant challenges for watchmakers as discs are much heavier than conventional hands, which not only affects power reserve but also leads to a drop in amplitude, particularly when all three discs advance simultaneously at the top of each hour. However, the SB08 is also a tourbillon, which makes things far more complicated in terms of power management. In fact, this is the first-ever tourbillon watch with both jumping hour and minutes. To do this, Armand enlisted the help of movement developer Mathieu Cleguer.

In

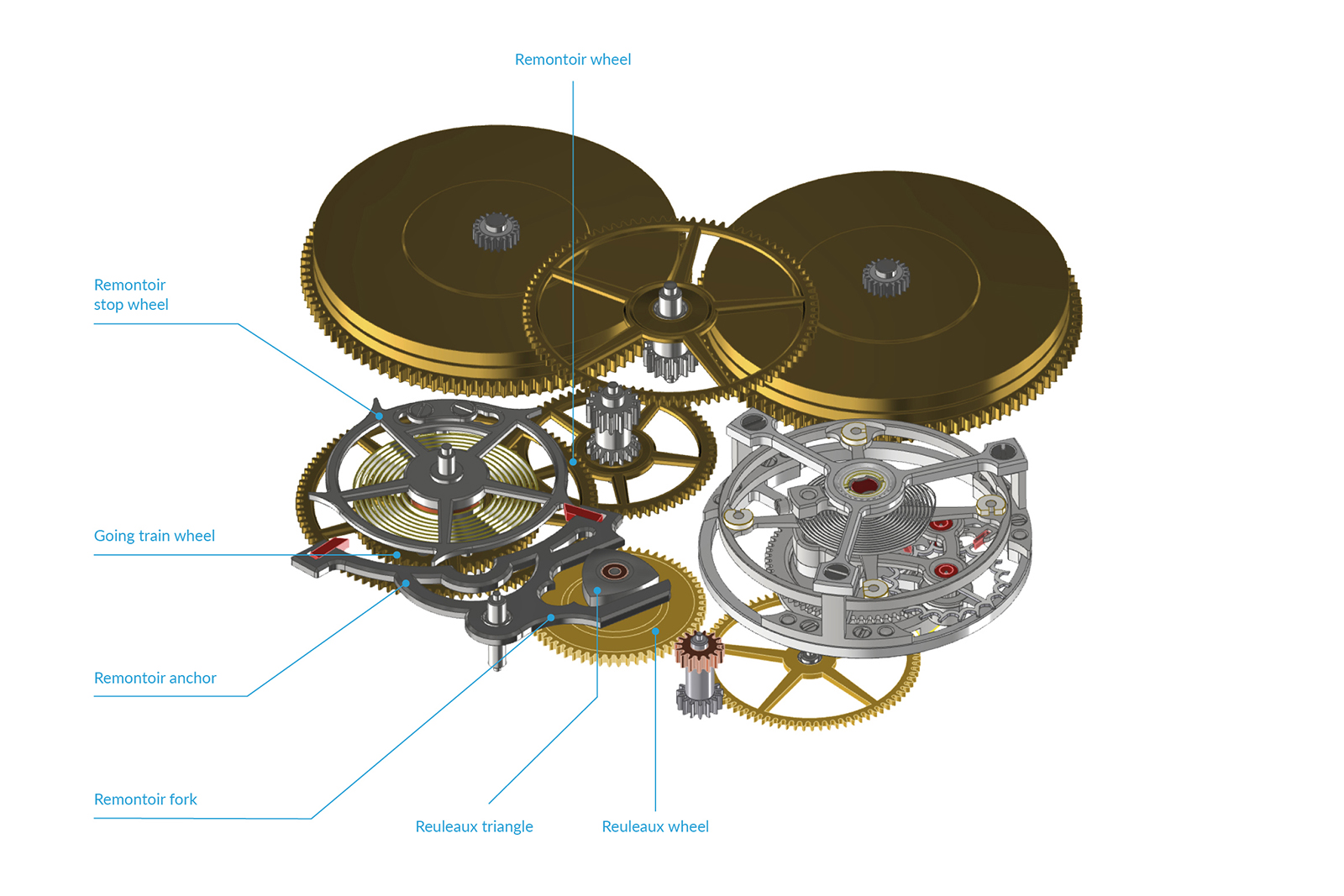

Part 1 of the series we ran, Mathieu had designed the movement with the crown wheel positioned at 12 o’clock, driving two parallel mainspring barrels. The gear train powers a remontoir that releases energy to power the jump of at least one disc each minute as well as drive the rotation of the tourbillon. The minutes unit disc is mounted directly on the pivot of the remontoir wheel, sequentially triggering the jump of the minutes tens and hour discs through a system of Maltese crosses.

Since then, the entire construction has evolved substantially, with notable refinements and developments, particularly in the areas of hand-setting and bridge design.

Fundamental changes in construction

Originally, the jumping display, which consists of Maltese crosses and three discs, was intended to be located on the dial side of the base plate. But for ease of assembly and adjustment, Mathieu decided to separate the chronometry part of the movement from the jumping display. As such, the jumping display is assembled on a separate plate beneath the dial and is connected to the base plate via a pinion that drives the minutes units disc directly.

Initially, the crown was intended to be positioned at 12 o’clock for symmetry. However, the team later opted to relocate the crown to the traditional three o’clock position. This was driven by a desire to infuse a sense of classicism into what will be a largely contemporary design, as well as to ensure ergonomic winding. Additionally, this also ensures the winding stem will be closer to the minutes units disc (more on that later).

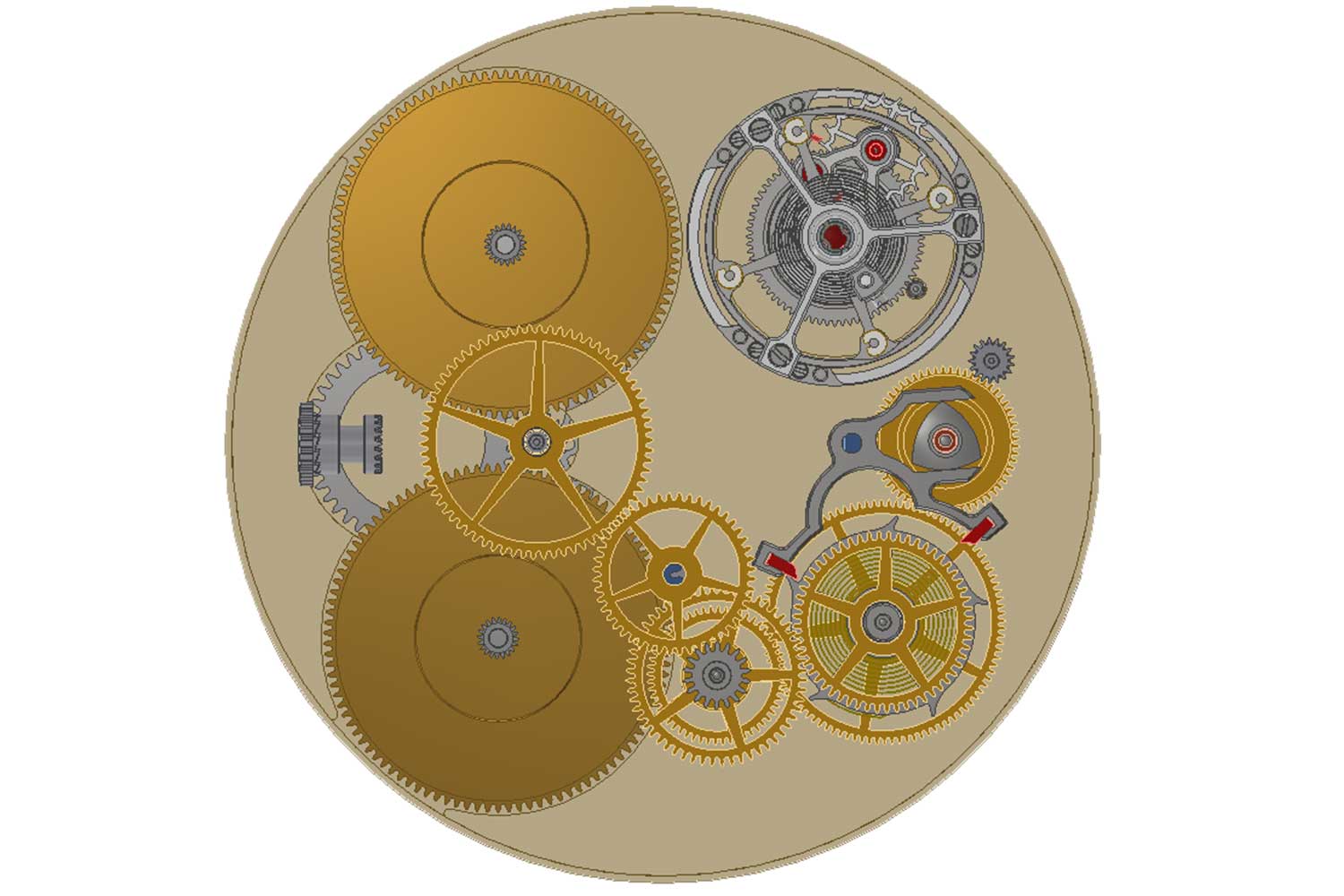

However, the process of moving the crown to three proved to be far easier said than done and it took numerous revisions to arrive at the final design. Initially, Mathieu decided to essentially rotate the movement by 90° such that the barrels now occupy the left half of the movement. At the same time, he had to make adjustments to the layout of gear train to visually optimise the available space that is now present at the bottom right quadrant of the movement. In the initial design (1A), he brought the tourbillon inward from the edge and added two co-axial, intermediate wheels before the remontoir wheel to occupy the empty space at the bottom right quadrant.

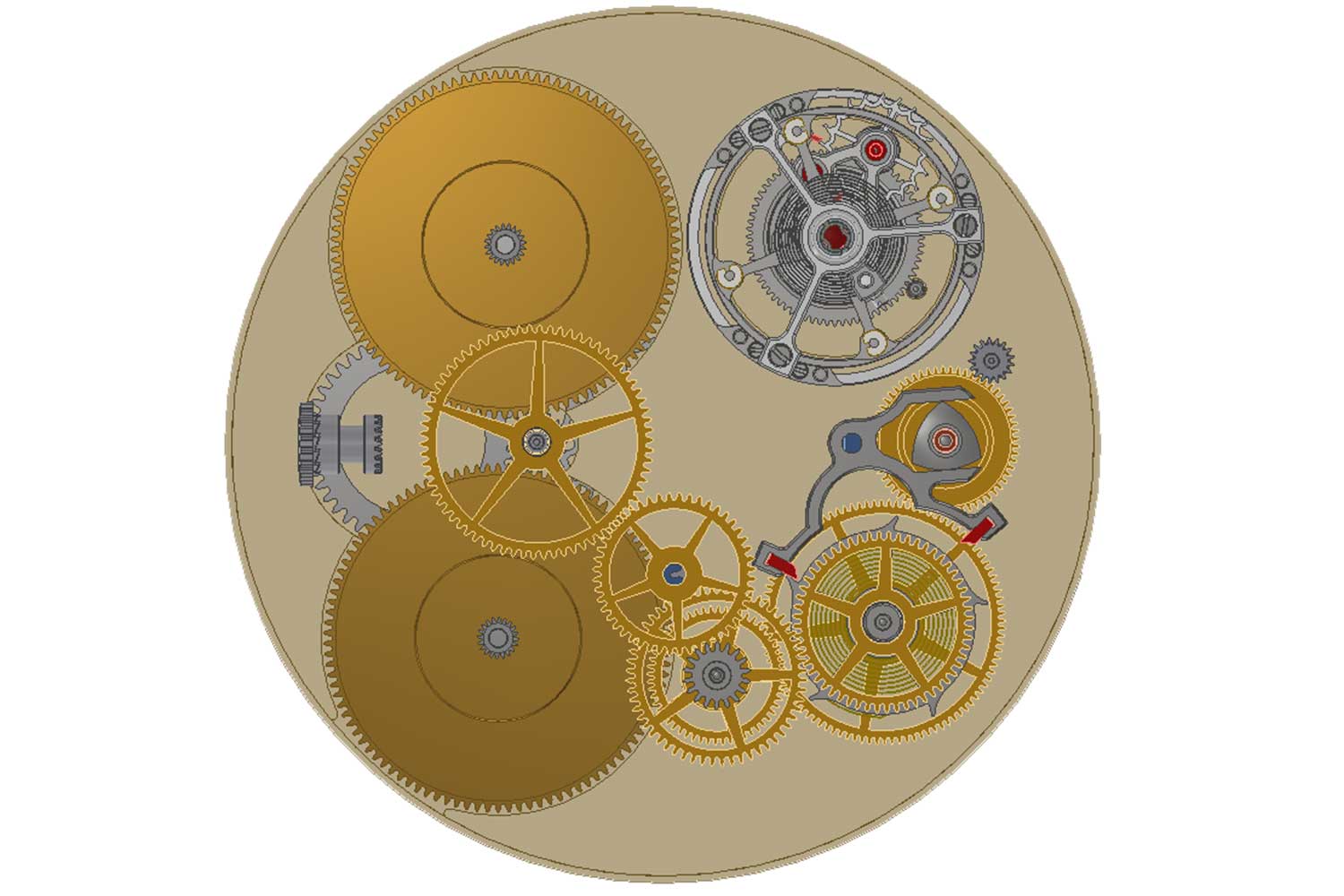

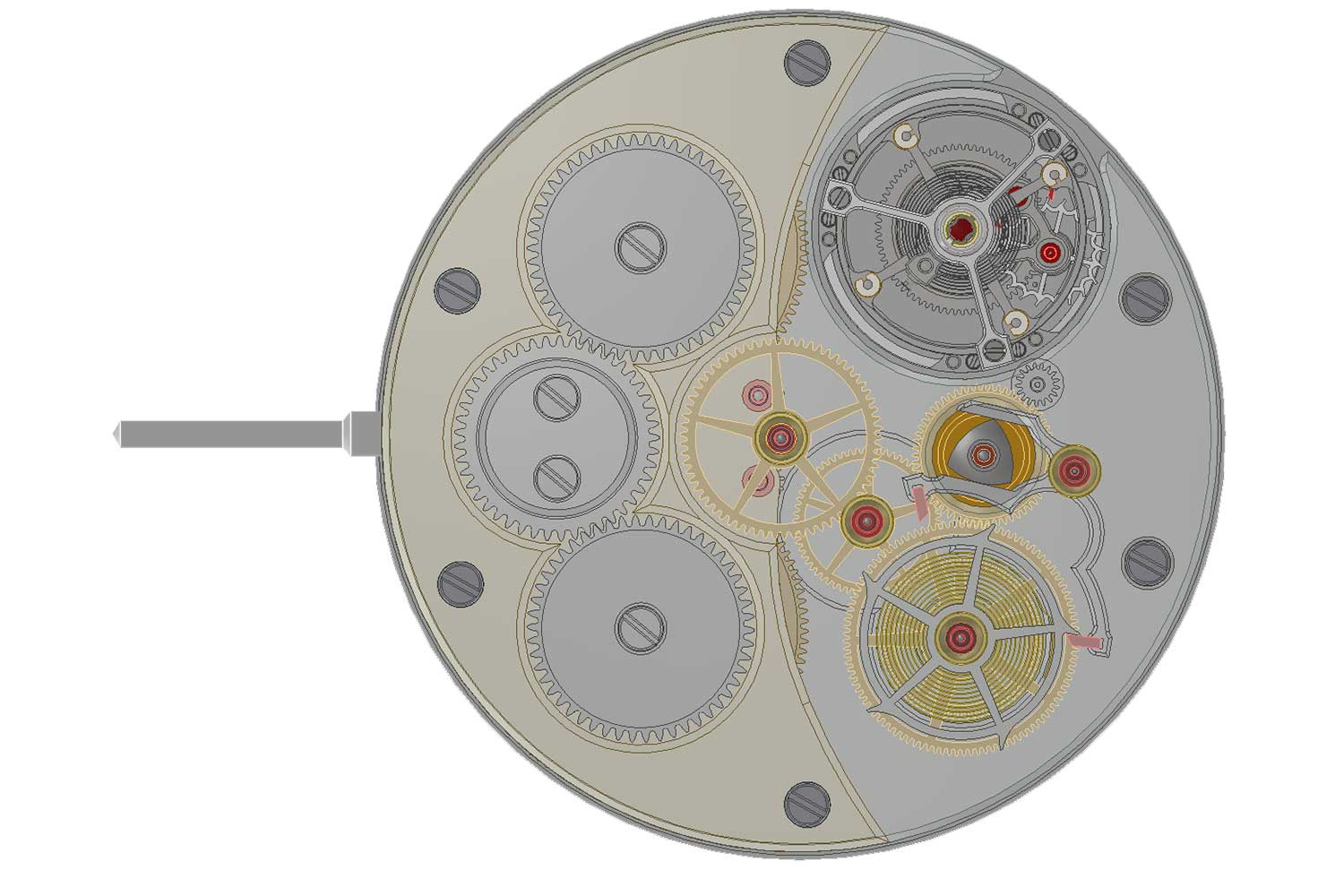

Figure 1A. The first design to relocate the crown to the three o'clock position

He also reconfigured the remontoir anchor and fork to reside further inside the movement, rather than at the edge. However, in this design, the co-axial wheels overlap the barrel and limits the height of the remontoir mechanism on the next axis. This was addressed in the next two designs (1B & 1C) in which he centralised the second and third wheels in the going train.

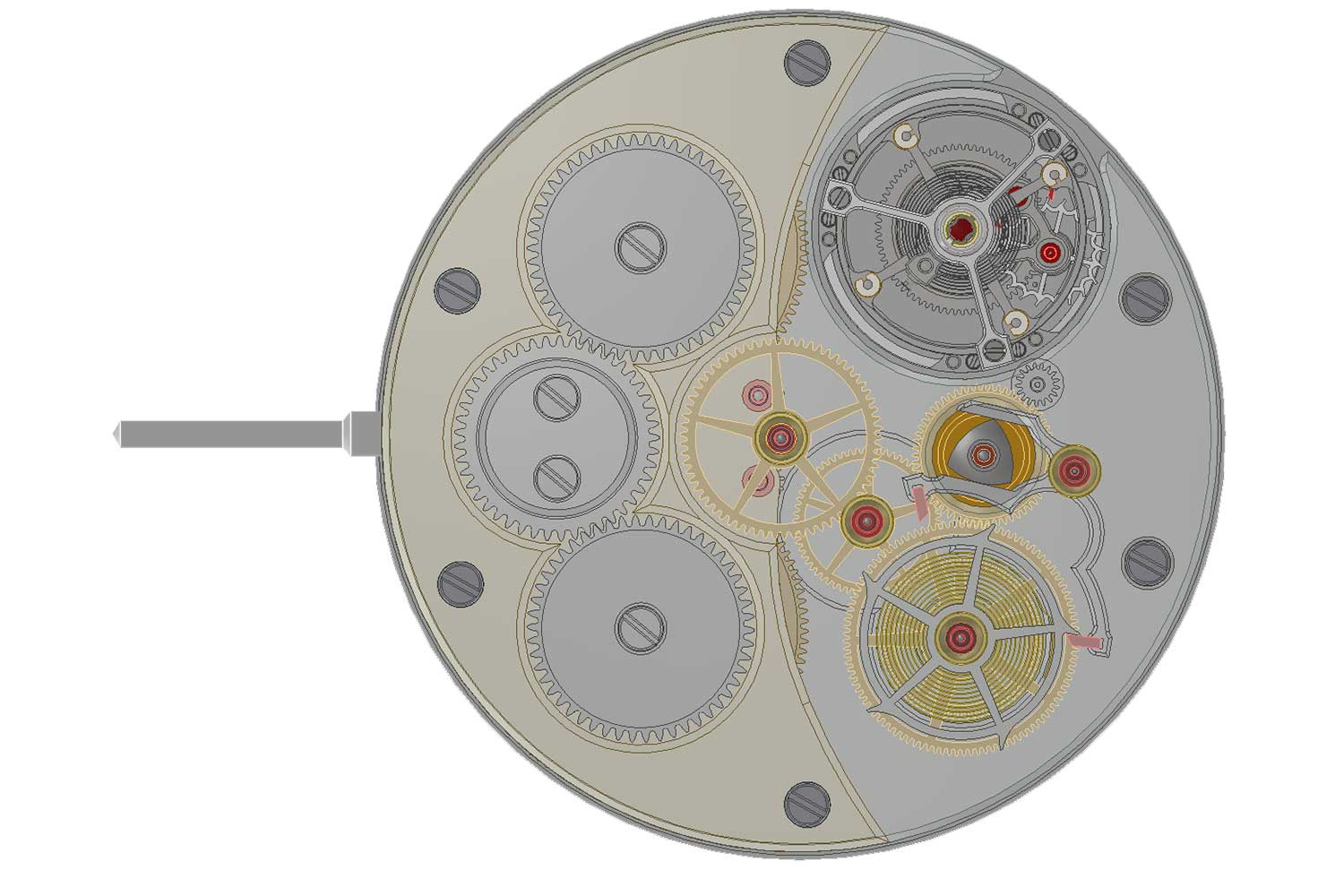

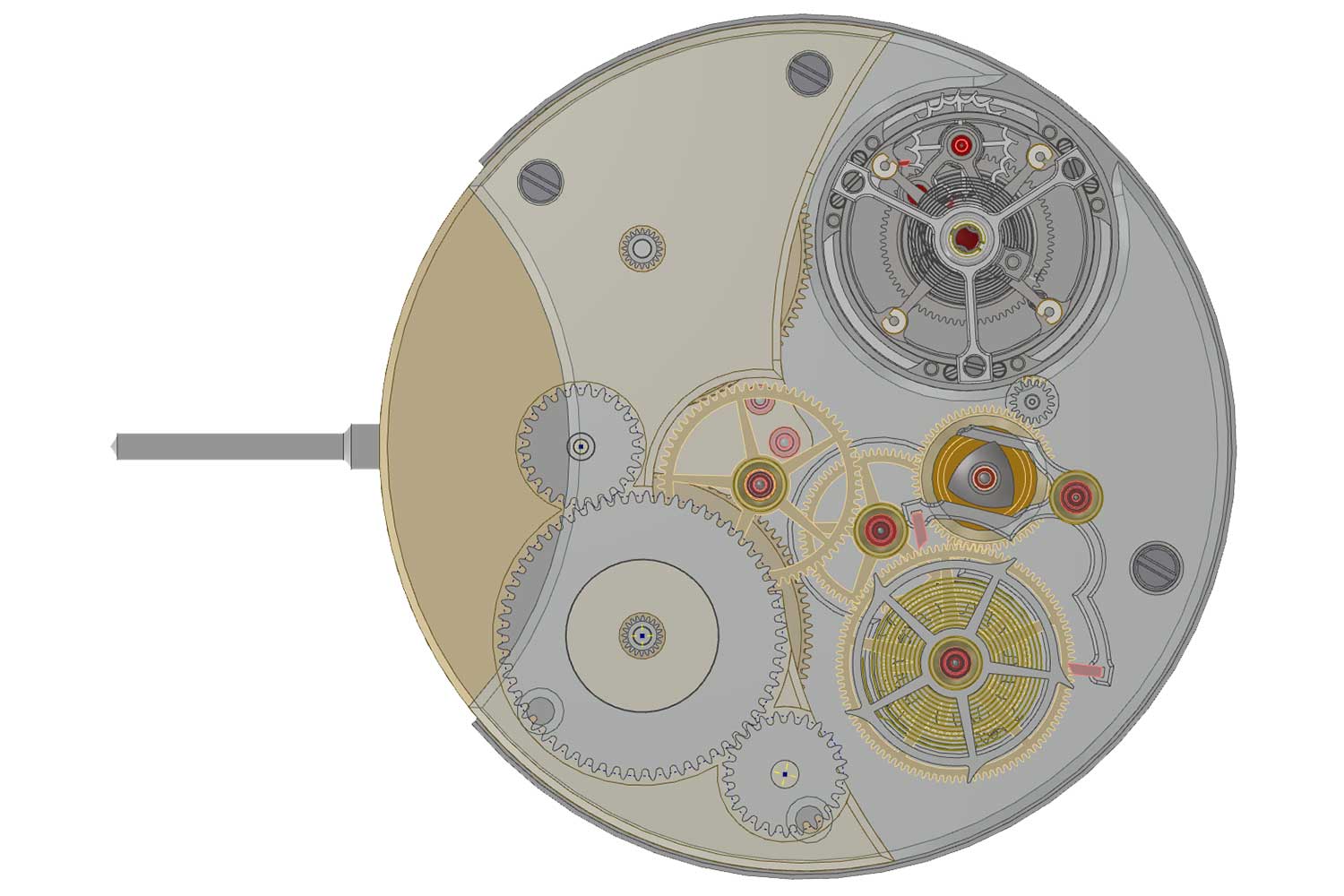

Figure 1B. In the second design, the second wheel is shifted toward the center to minimize overlapping and is driven by the barrels via pinions

Figure 1C. The third design, where the barrels are mounted lid up, with the ratchet and crown wheels located on the dial side. The three wheels located on the left quadrant form part of the time-setting train in order to reach the minutes disc

However, a more significant challenge arose when designing the time-setting mechanism. In a watch with conventional hands, time can be adjusted when the sliding pinion comes into contact with the minute wheel in the motion works via an intermediate wheel. However, in this case, the intermediate wheel has to be connected to the pinion of the minute units disc, which is too far away. A long and convoluted train of wheels had to be introduced to traverse the distance.

Additionally, during time-setting, the remontoir has to be isolated to ensure precise adjustment. Consequently, the minutes units disc can no longer be affixed to the pivot of the remontoir wheel. At the same time, Armand and Mathieu both felt that vertical symmetry is visually more compelling than horizonal, and they returned to where they started.

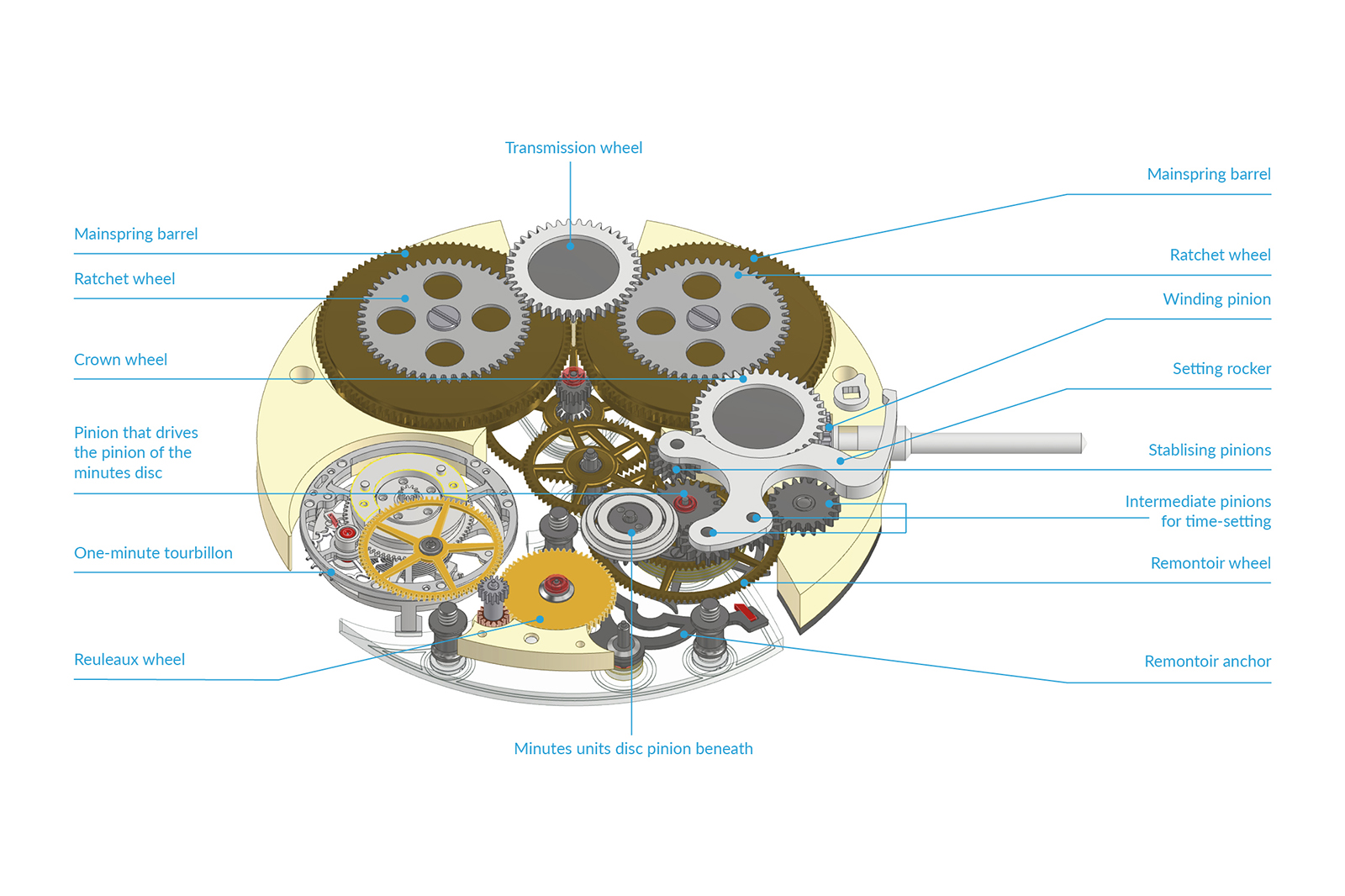

In the final design, the barrels are located at the top of the movement. They are mounted lid up from the bridge side with the ratchet wheels located beneath. As such, the crown wheel is also located on the dial side of the movement.

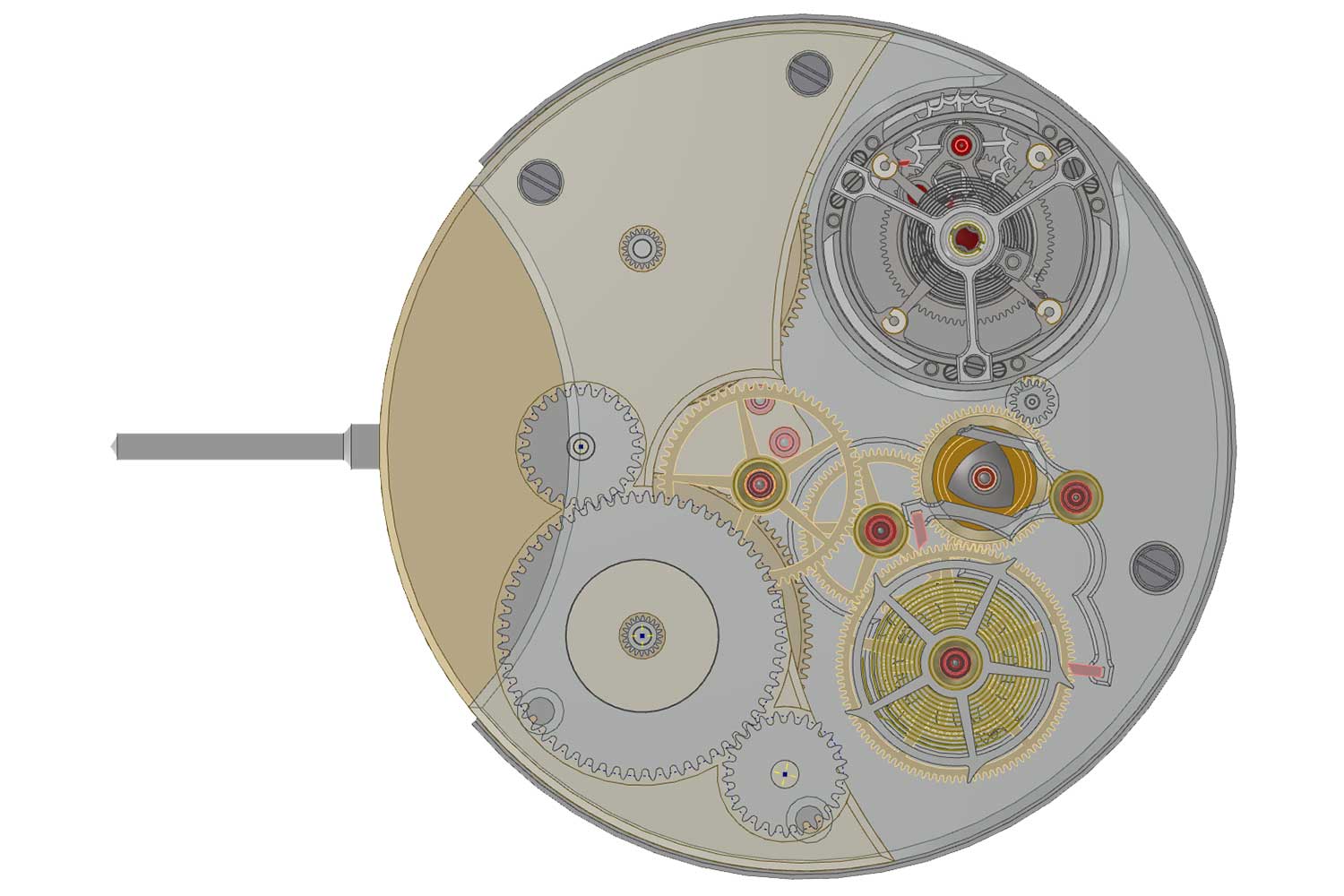

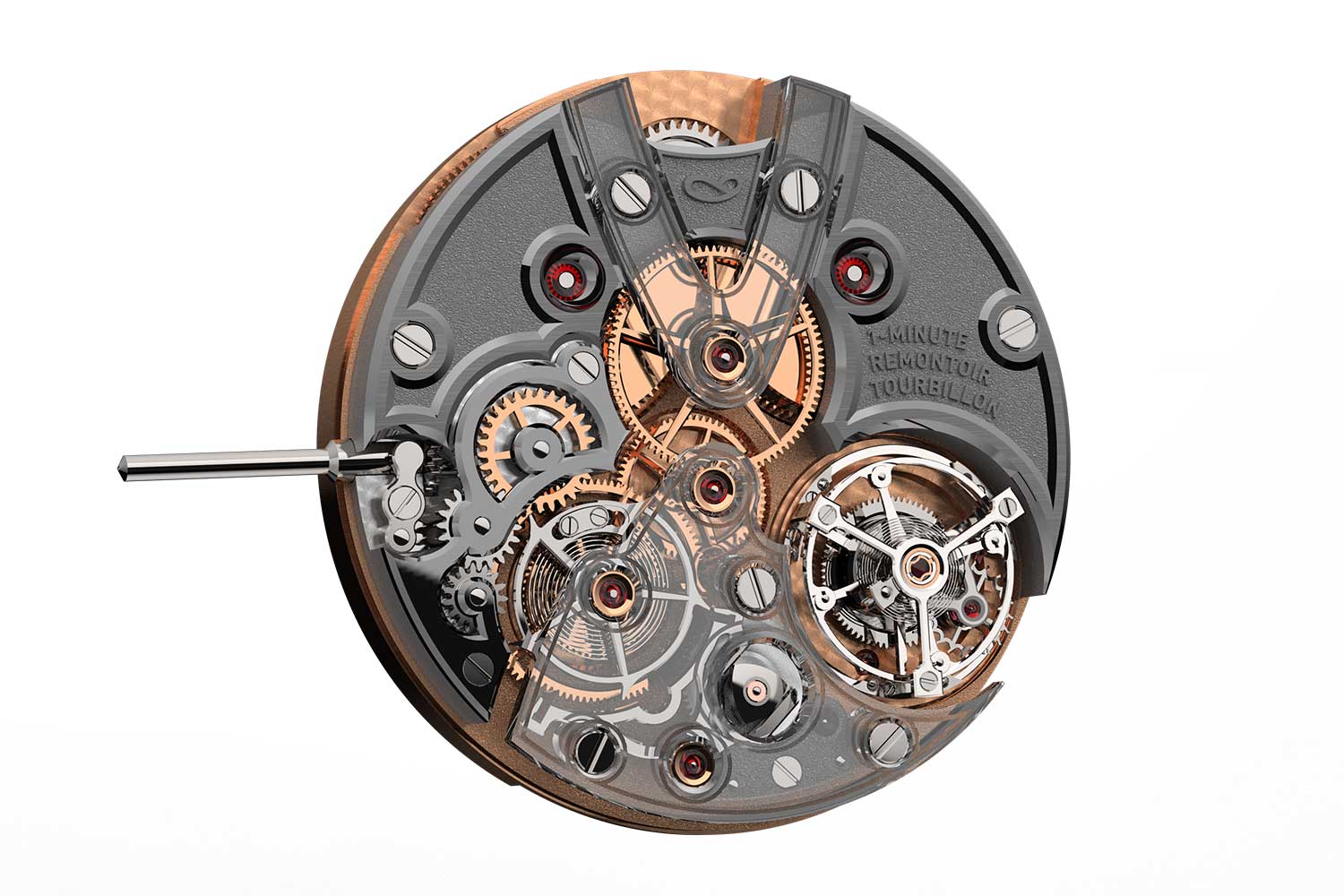

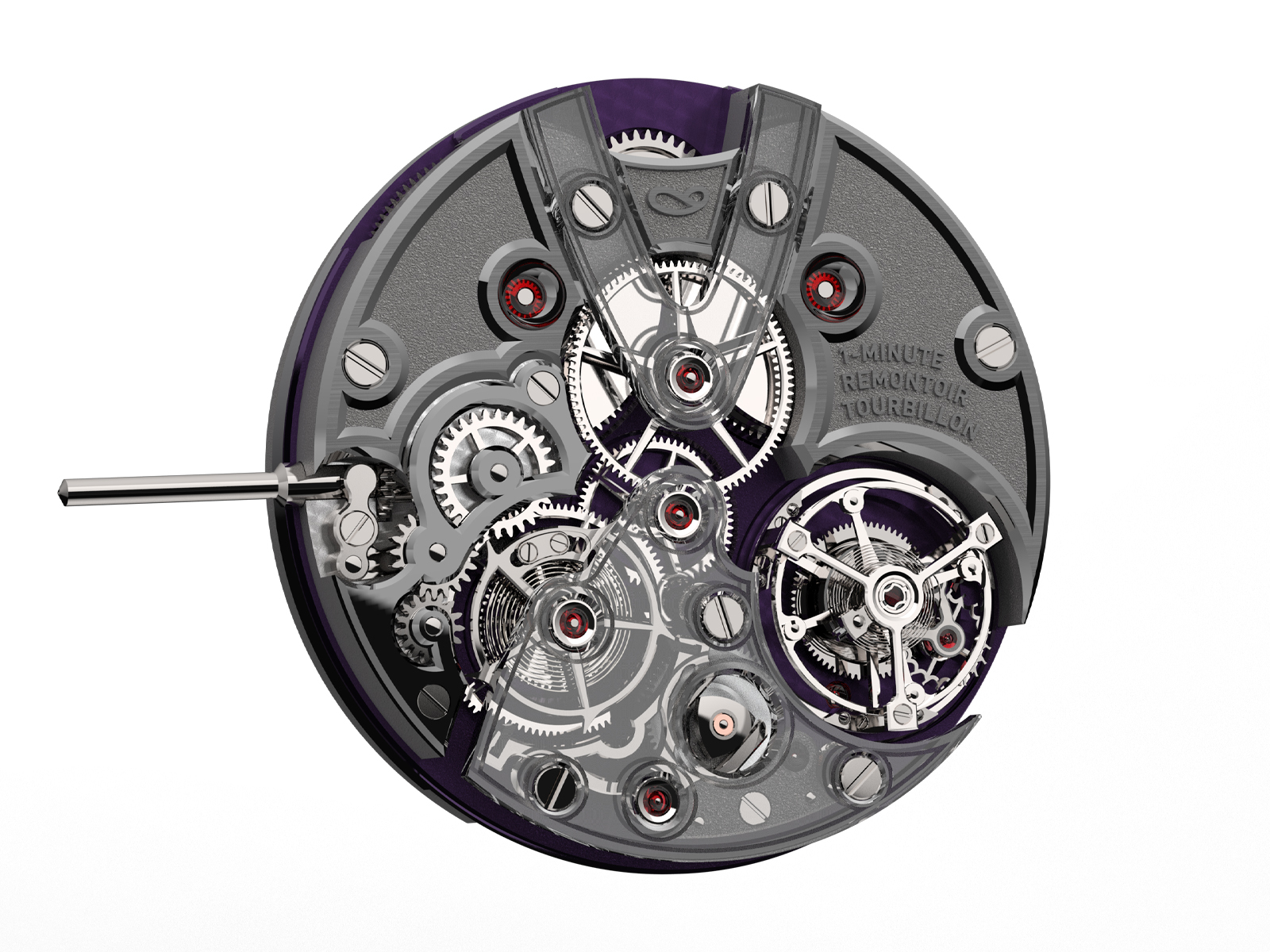

The final design

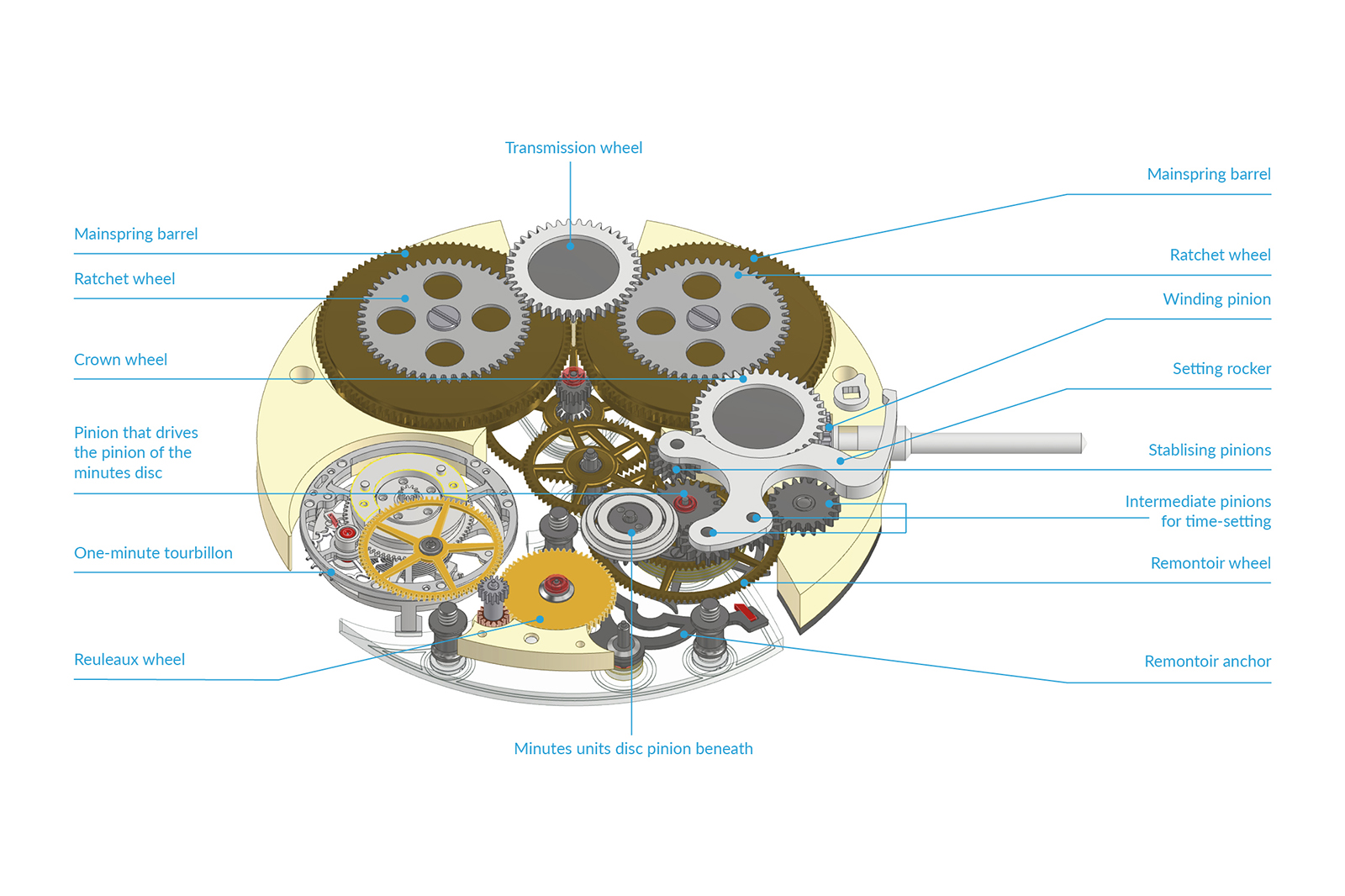

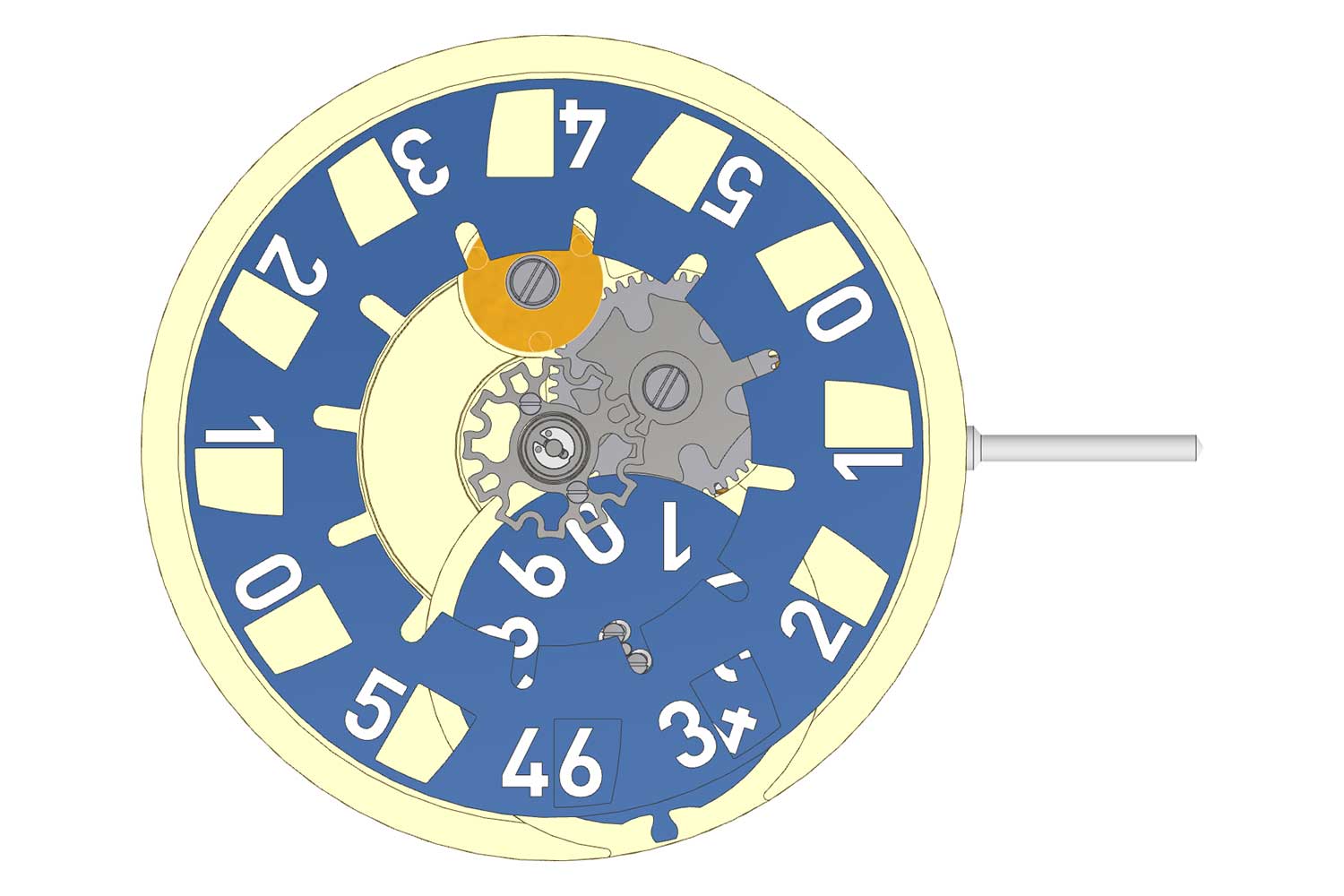

Dial side view of the movement with the base plate removed

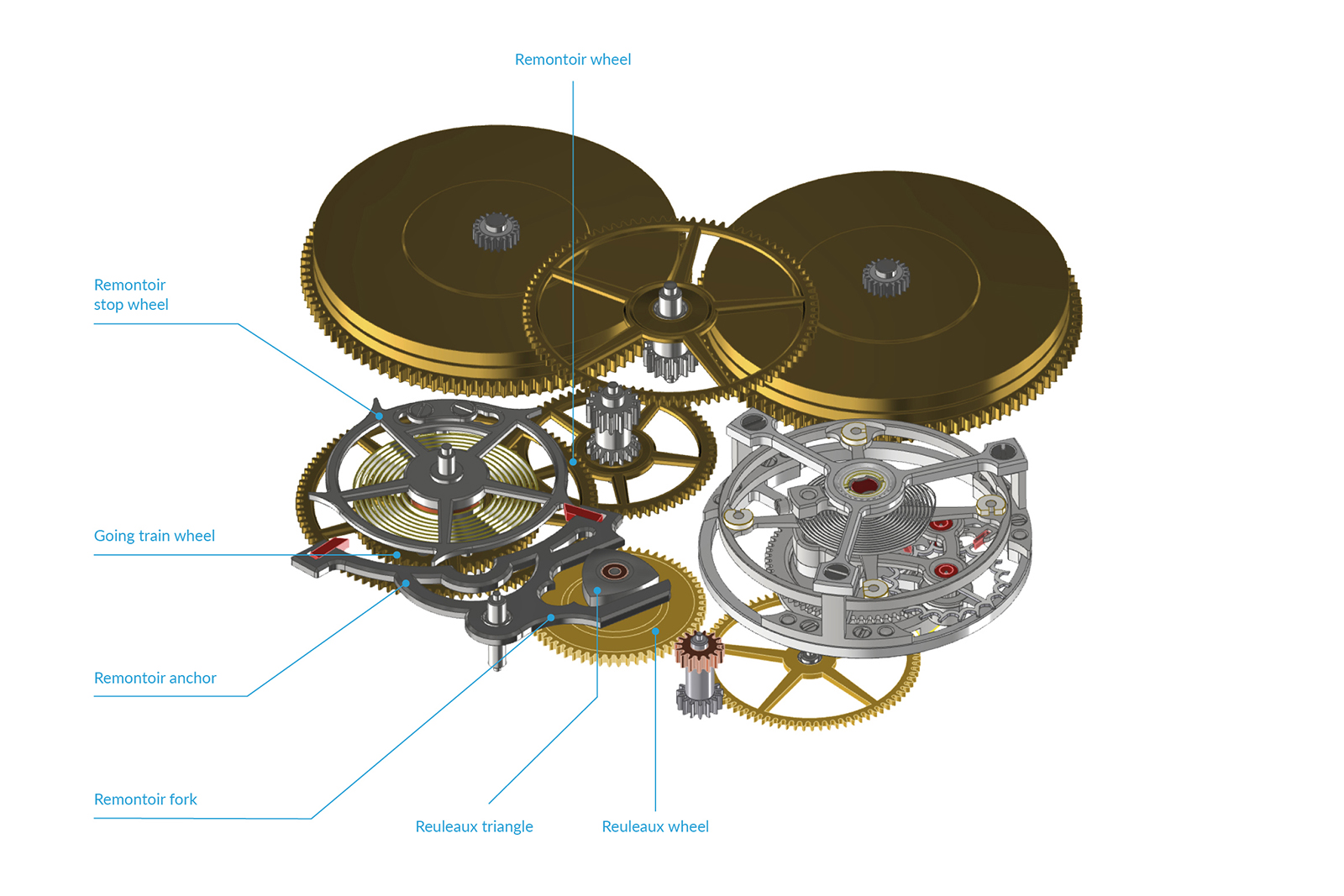

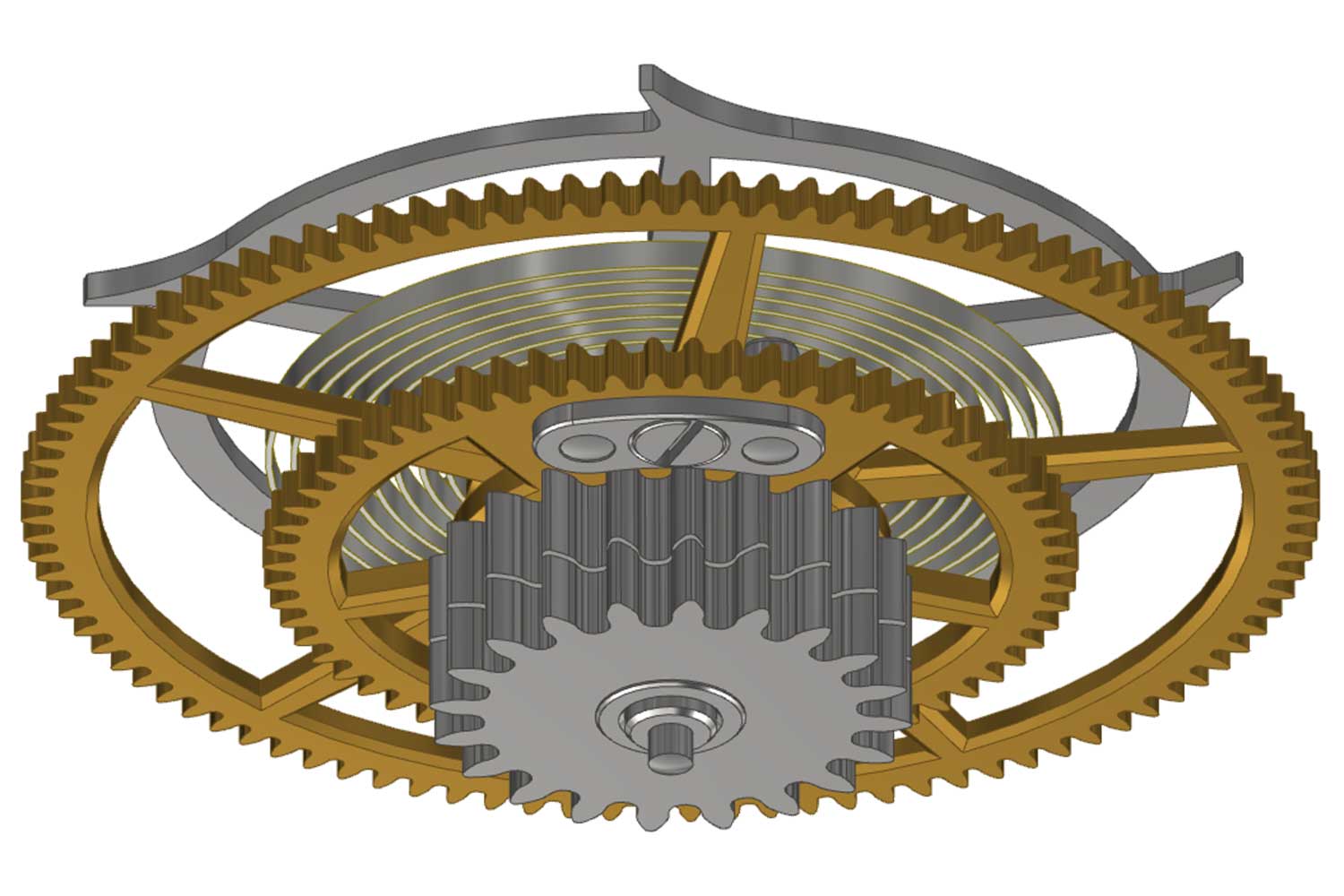

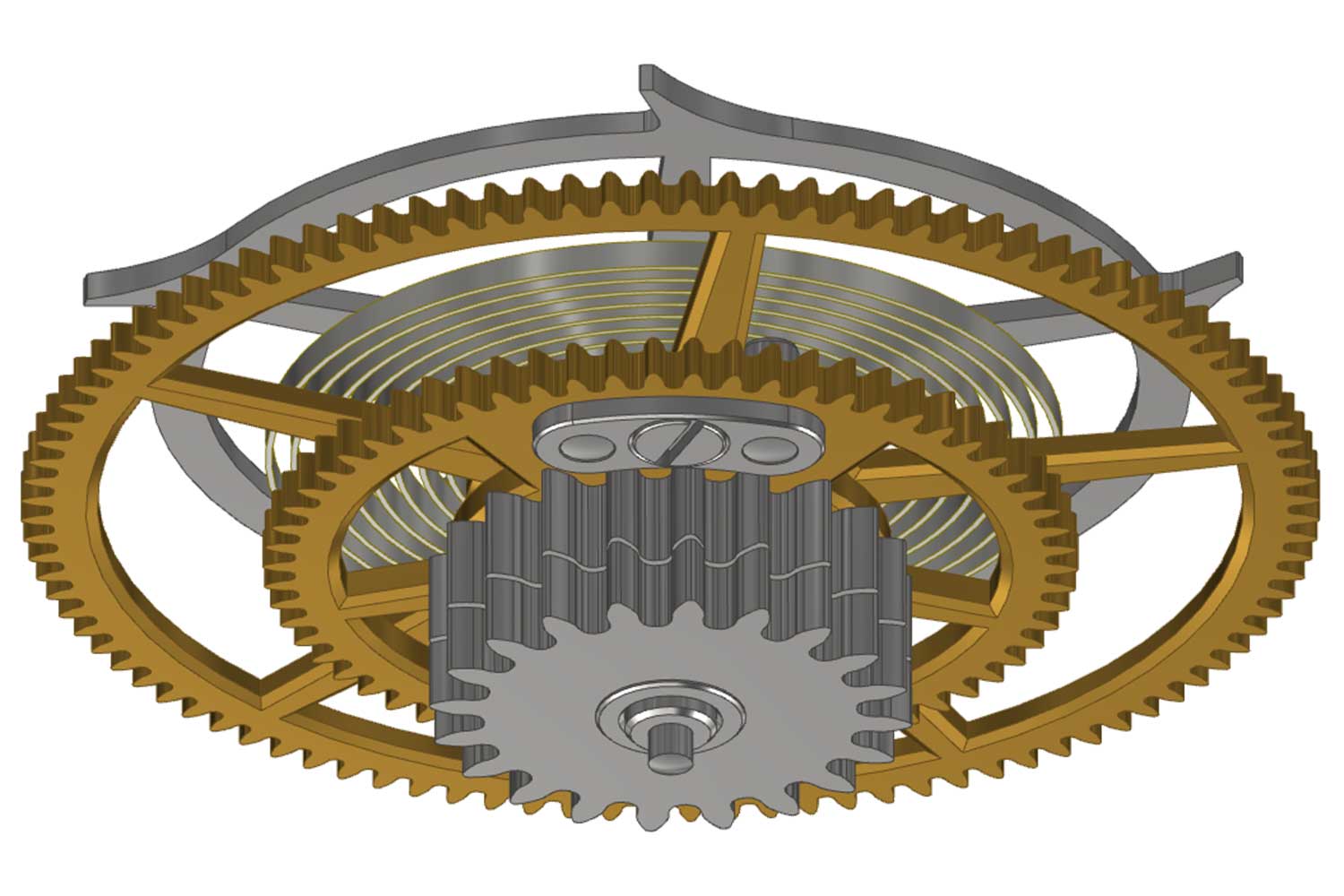

As before, the remontoir is located on the fourth wheel (third wheel in the gear train). The outer curve of the remontoir spring is pinned to a stud and fastened to a mobile stud holder on the ratchet stop wheel. The stud holder can be moved sideways to adjust the stiffness of the spring. The spring is wound by the gear train but is released only every minute by the advancement of the ratchet stop wheel.

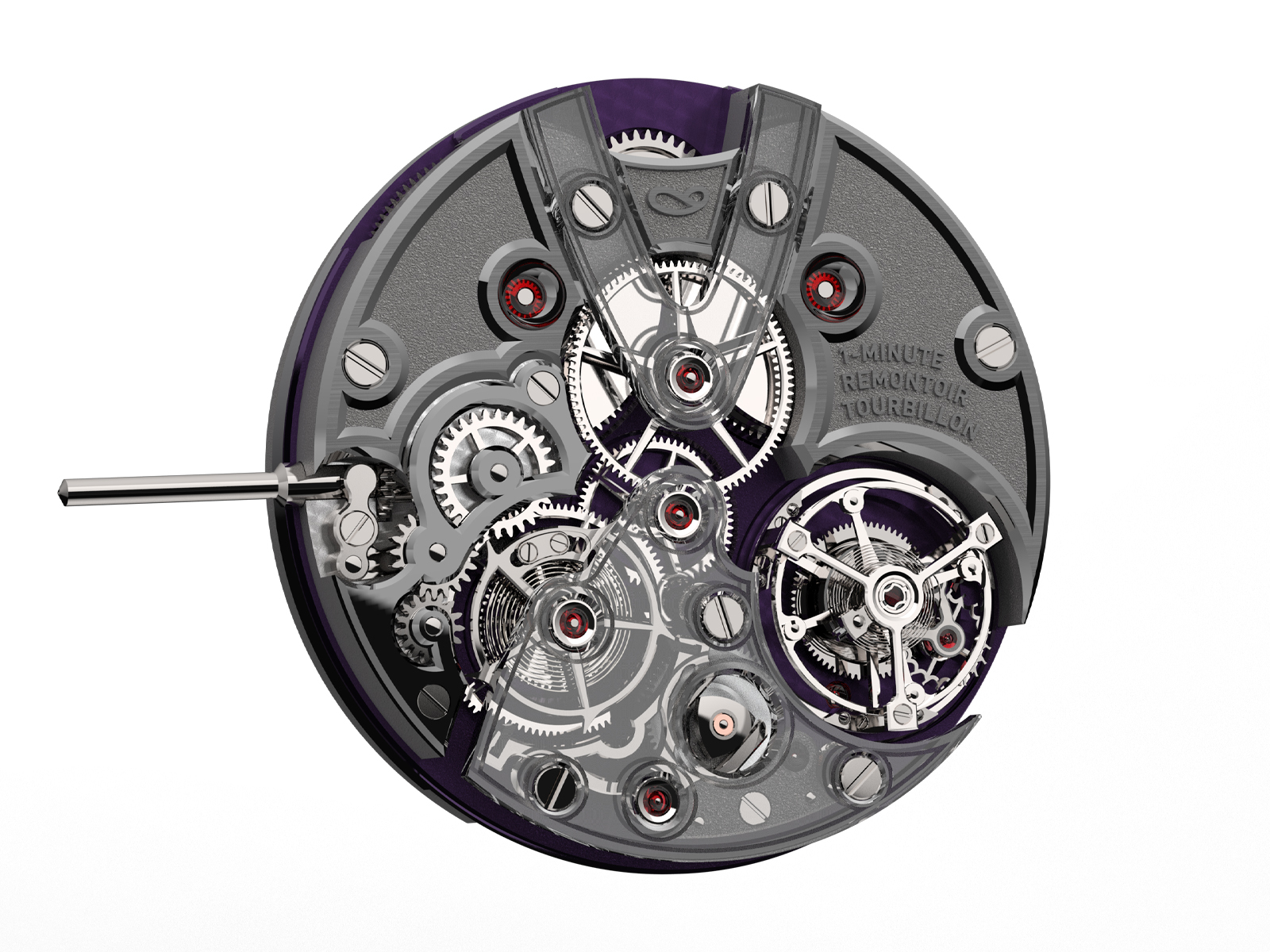

The one-minute remontoir mechanism

The stop wheel is unlocked by a pallet jewel on an anchor, which is connected to a fork. The motion of the fork is in turn governed by a Reuleaux triangle located on the fifth wheel. Thus, at every 60° turn of the Reuleaux triangle, the anchor unlocks one teeth of the stop wheel, releasing energy to the rest of the gear train until the second jewel pallet prevents the stop wheel from advancing further, thereby tensioning the remontoir spring once again. Beneath the fourth wheel on the same axis are two pinions – one pinion is fixed to the staff of the ratchet stop wheel while the second pinion is rotatably mounted.

Pinion of the remontoir wheel above and the pinion that drives the minutes units disc below

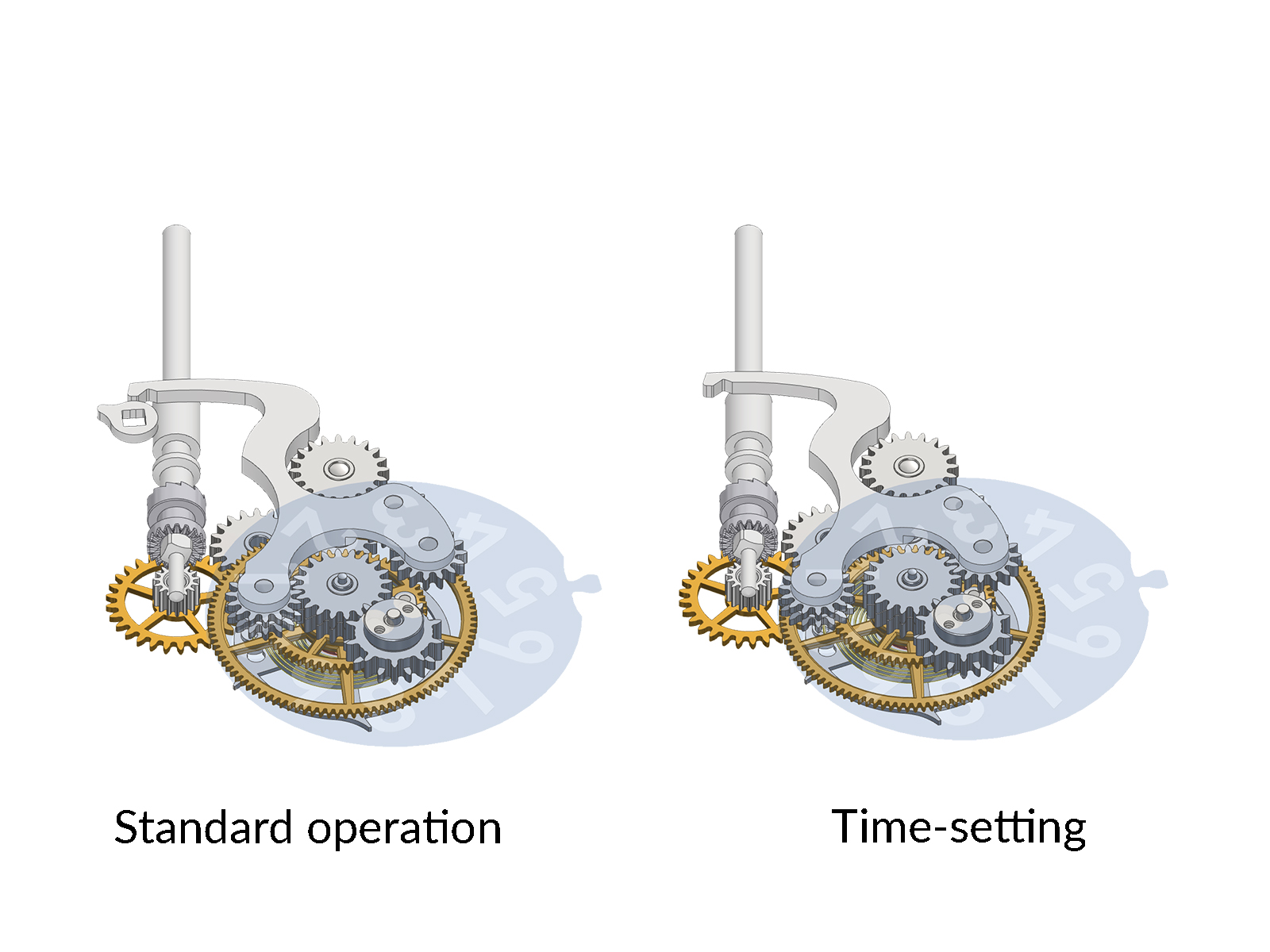

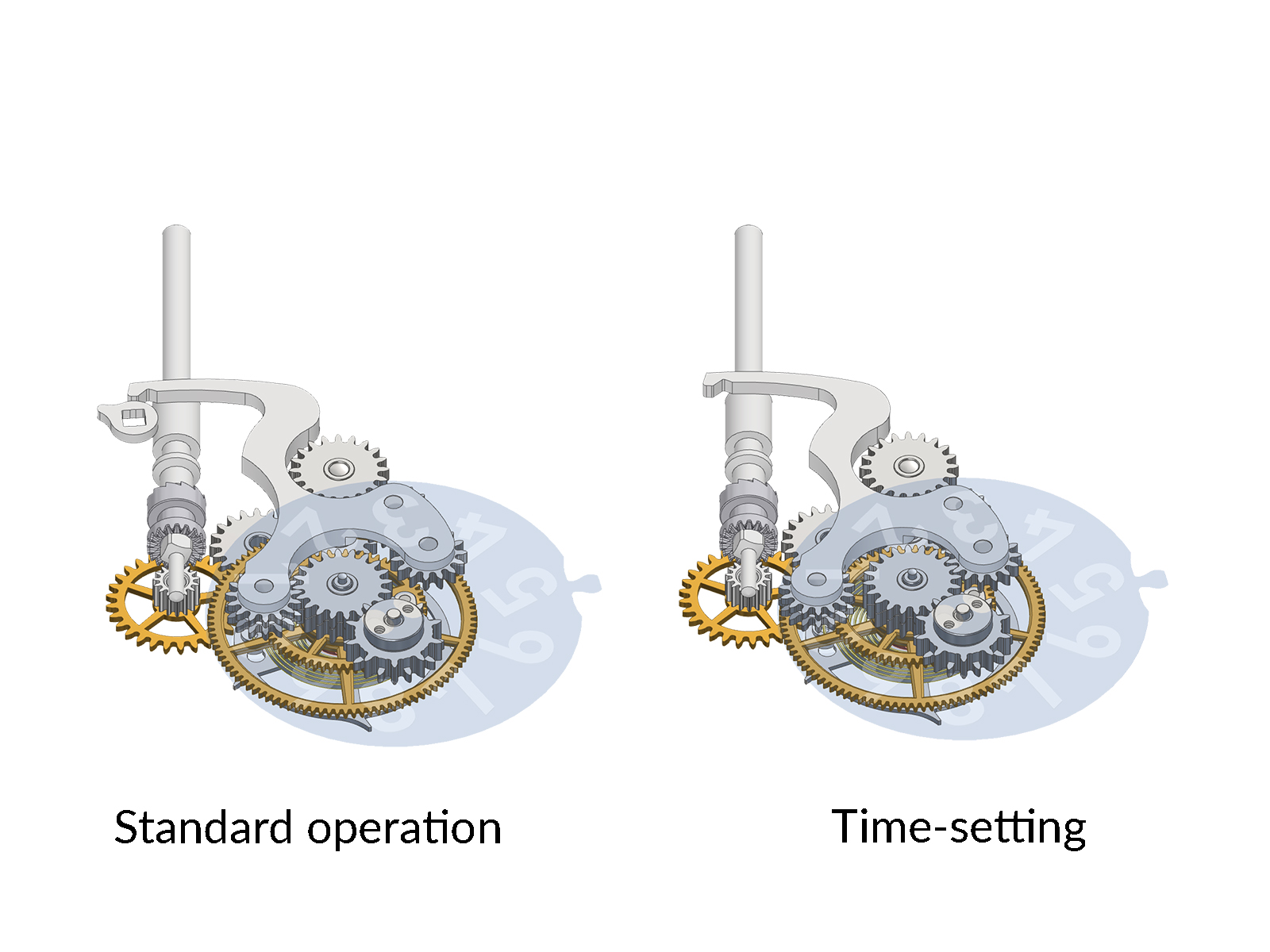

The most formidable challenge, aside from the intricacies of the complication itself, lay in the design of the keyless works. Due to the unconventional display that is powered by the remontoir, designing the keyless works, particularly the time-setting mechanism, proved to be far from intuitive. The team decided that the hours and minutes will be set in the first position and winding the mainspring barrels is achieved with the crown in the neutral position.

Mathieu arrived at an ingenious design that isolates the remontoir during time-setting. The time-setting mechanism has a rocker that carries a set of intermediate pinions — two on one end and a pair of superimposed pinions on the other. During the standard operation of the watch when the crown is in the neutral position, the superimposed pinions, which are fixed to a staff by a pin, meshes with the two pinions beneath the remontoir wheel, synchronising them to drive the pinion of the minutes disc.

But when the crown is pulled out to the second position to set the time, the rocker pivots and the superimposed pinions disengages from the pinions on the remontoir staff to allow them to rotate independently. At the same time, the other two pinions on the free end of the rocker is positioned to be driven by a third pinion, which is in turn driven through a series of gears by the intermediate winding wheel. The outer pinion drives the bottommost pinion on the remontoir staff, which in turn drives the pinion of the minutes unit disc, effectively isolating the remontoir.

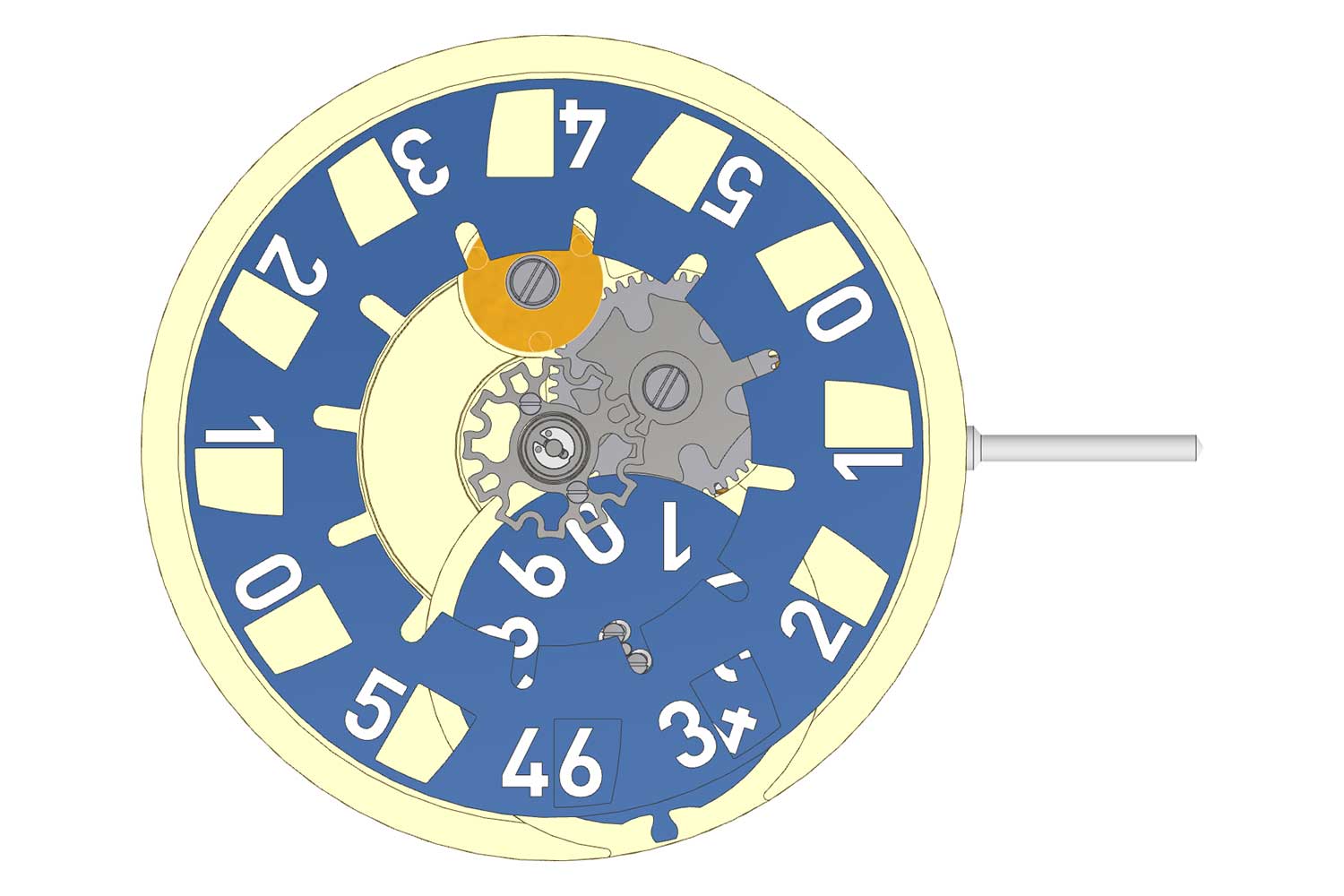

The jumping time display itself has also been refined. The pinion of the minutes units disc is driven by the pinion of the remontoir wheel, enabling it to leap forward at the top of each minute. Every 10 minutes, the finger on the disc advances a six-branch Maltese cross that is attached to a 60-minute intermediate wheel. It drives a smaller intermediate wheel at a 2:1 ratio, and affixed to this wheel is a cam bearing three equidistant raised hooks, functioning as fingers to incrementally advance the minutes tens disc. The minutes tens disc has been designed with 12 branches, which is necessary for controlled intermittent motion.

The time display mechanism with the hour disc removed.

As the Maltese cross completes a full rotation in an hour, a finger piece advances a 12-branch Maltese cross, to which the hour disc is affixed. The hour Maltese cross now features a skeletonised design to reduce inertia.

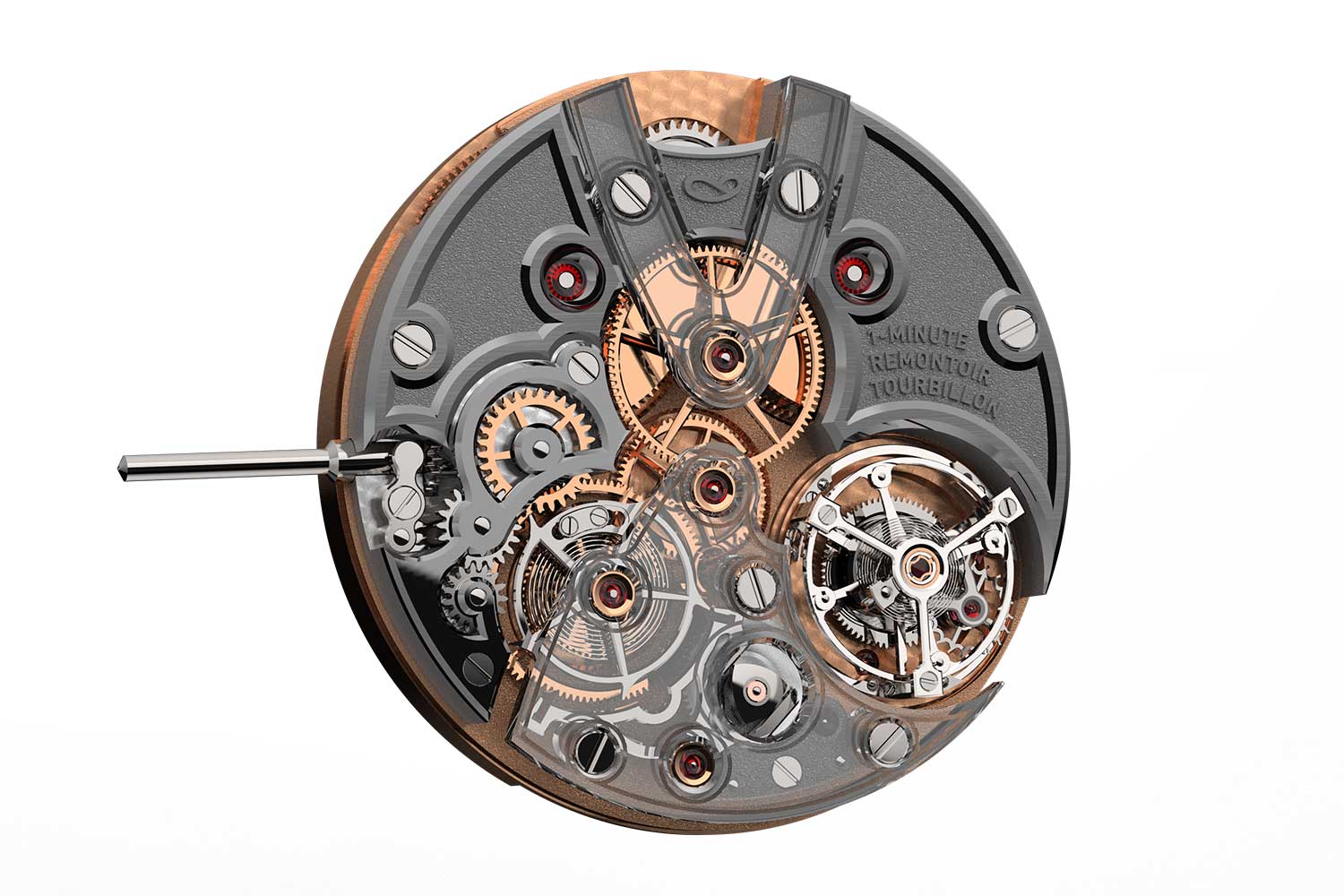

Bridge design and finishing

The bridge layout has undergone a complete overhaul, resulting in a significantly more striking and exuberant movement. The new design is intended to showcase a variety of finishing techniques and to make as much of the components visible as possible. The base plate will be finished with frosting while its recesses will be decorated with perlage. The barrels are supported by a bat-shaped bridge, which is accentuated by a raised border that is straight-grained on its top surface and polished, bevelled on its outer edges. Its recesses, on the other hand, are frosted. It features large jewels that sit in deep, polished countersinks.

The bridge layout was designed to show off as much of the wheel train and the other components as possible as well as a variety of finishing techniques

The second wheel is supported by a V-shaped sapphire bridge while the entire remontoir mechanism is left exposed beneath a larger sapphire bridge. Additionally, this larger bridge has an aperture, providing a clear view of the Reuleaux triangle in action. Notably, all the exposed wheels in the gear train, along with the remontoir stop wheel will have polished and bevelled spokes with sharp internal angles. Lastly, supporting the intermediate wheel and pinions in the keyless works on the left is a black-polished bridge of an intricate shape, which lends itself to a total of nine sharp internal angles.

This example features monochromatic wheels and bridges contrasted against a striking purple base plate

Right from the outset, the movement was designed for the aperture of the jumping display to be positioned at six o’clock on the dial, which leaves the rest of the dial free to be embellished. Armand, however, decided to design another version of the dial for those seeking a touch of French flair. It features a cut-out that resembles the shape of a keyhole, providing a peek into the inner workings of the display mechanism. It enables a clearer view of the jumping action of the hour disc as the central hub is exposed. Additionally, the skeletonised Maltese cross behind the hour hub can also be seen engaging with a finger piece on the right.

The smoked sapphire aperture reveals the central hub of the hour disc. Behind it lies the skeletonized Maltese cross, which is advanced by a finger piece on the right.

This design is particularly well-suited for guilloché and stone dials. This example features a lapis lazuli dial, complemented by a blue sapphire aperture

A nuanced yet impactful element that truly elevated the design of the dial was the addition of an elliptical metal border. It subtly draws emphasis to the digital display, contributing to a more refined appearance overall.

The solid dial version is the perfect canvas for pictorial decoration such as miniature painting and engraving

An example with a lab-grown osmium dial under a domed sapphire crystal

Armand and his team are progressing to the next phase of development, where they will consult with movement makers and specialists. Once again, they remain open to feedback and new perspectives along the way. For enquiries about the subscription series, please reach out to Sartory Billard through their

official website.