In this three-part series, we follow the development of Sartory Billard’s SB08, a watch that combines two power-hungry complications, while delving into the engineering and craft behind its creation.

Sartory Billard is best known for offering an incredible degree of customization and artisanal details on time-only watches that fall below the €10,000 mark. The brand’s breakout SB04 model along with the watches that followed have struck a harmonious chord with collectors, predicated on a formula of crafting exquisite external components that encase a dependable mid-range movement. This approach has yielded watches that not only offer an array of customization options but also remain within reach for a wide range of budgets. However, today, the brand is working on a tourbillon watch, and not just any tourbillon, but one that is highly sophisticated, incorporating a one-minute remontoir that powers three discs for a jumping hours and minutes display.

This marks a remarkable stride for the brand, and over the course of this three-part series, we will be documenting the design and development process up until its launch in 2024. Just as with any creative endeavour, it remains susceptible to modifications and fresh insights along the way.

Sartory Billard was founded in 2015 by Armand Billard, an industrial designer and an owner of a design agency, whose work spanned a diverse spectrum, encompassing everything from computers and phones to goggles. His initial foray into wristwear came about when he designed tracking devices for a client, specifically tailored for individuals caring for someone with Alzheimer’s. Shortly thereafter, he, along with his friend Ludovic Sartory, had an idea to design a watch to mark their 40th birthdays, purely for their own enjoyment. While this may sound like a common pursuit in collector circles today, usually resulting in a customized watch, the duo ended up sourcing for suppliers and creating their own watch from scratch. This eventually led to the birth of his own business.

Armand Billard

His fascinating journey is one marked by trial and error, which when viewed in hindsight makes for a valuable blueprint for budding startups. Armand’s first three watches – the SB01, SB02, and SB03 – all featured unconventional case designs that bore witness to Armand industrial design expertise. While these cases had a unique charm, they had a niche appeal among collectors. Ludovic Sartory eventually withdrew from the venture after the various setbacks but Armand, on the other hand, sold his design agency in 2017 to devote himself completely into his next watch. By then, the essential ingredients were already present, the techniques just needed to be further honed and perfected.

SB01

SB02

SB03

For his fourth watch, the SB04, Armand shifted gears and channeled his focus on the dial’s artistry, while embracing the familiarity of a classic 40mm round case. The dial, which comprised of a simple but striking skeletonized chapter ring that was laser-cut, along with skeletonized hands, provided a canvas that allowed for a maximum degree of freedom in dial materials and decoration, all while retaining a recognizable aesthetic. Meanwhile, the 40mm case, while circular, adopted a clever three-part construction that allowed for three kinds of finishing – polishing on the bezel, sandblasting on the case middle and satin-brushing on the lugs which were integrated with the case back. Armand depended on Swiss suppliers for the case, but he had to personally acquire the skills and knowledge to manufacture the titanium dials, chapter rings, and hands by himself. Within the watch was an automatic central seconds movement, which was initially an STP calibre but has now transitioned to a La Joux-Perret movement. The price for a custom creation starts at €4,200. The SB04, as we know it, was a major hit and continues to be the brand’s best-selling model.

SB04

SB04

The orders kept him occupied in the following years as he worked on fine-tuning and elevating his proposition. Last year, he introduced the hand-wound SB05, a watch that is intrinsically more refined. While it still retained the distinctive chapter ring, the dial was now more complex, comprising of four components, each individually customizable: the chapter ring itself, an outer ring, an inlaid central piece as well as an inlaid small seconds subdial. The case was now more classically proportioned at 38.5mm and the movement within is the La Joux-Perret 7380 calibre with a 90-hour power reserve. It was followed by the SB07 this year, a sports watch with an integrated bracelet and once again, a fully customizable dial.

SB05

SB05

SB07

SB07

Armand’s path to this juncture is a testament to his extraordinary dedication and determination. Having gained a more profound insight into his clientele and the market, he is now venturing into complications, this time starting right at the top, with a highly sophisticated flying tourbillon movement.

Armand’s commitment to transparency and openness extends beyond the design process itself. The manner in which he found a movement constructor for the SB08 was equally unconventional. Armand had designed a dial featuring a jumping hour and minutes display and, in a unique twist, he shared an image of it on Instagram, accompanied by a caption that read, “If you can create this movement, contact us.” He then got a response from Mathieu Cleguer, a 33-year-old movement constructor who has spent the last decade developing movements for a variety of brands such as Breva, Emile Chouriet and most notably Akriva, where he participated in the development of the renowned AK-06 movement. Since then, Mathieu has been designing and refining the SB08 movement.

The initial sketches of the dial

To maintain the scope of customization, Armand decided on a digital hours and minutes display as this would free up a vast expanse of the dial and allow for a wide range of customization options, including miniature painting, gem-setting and guilloché. As such, the tourbillon, which is typically located in an aperture at six o’clock, is deliberately concealed.

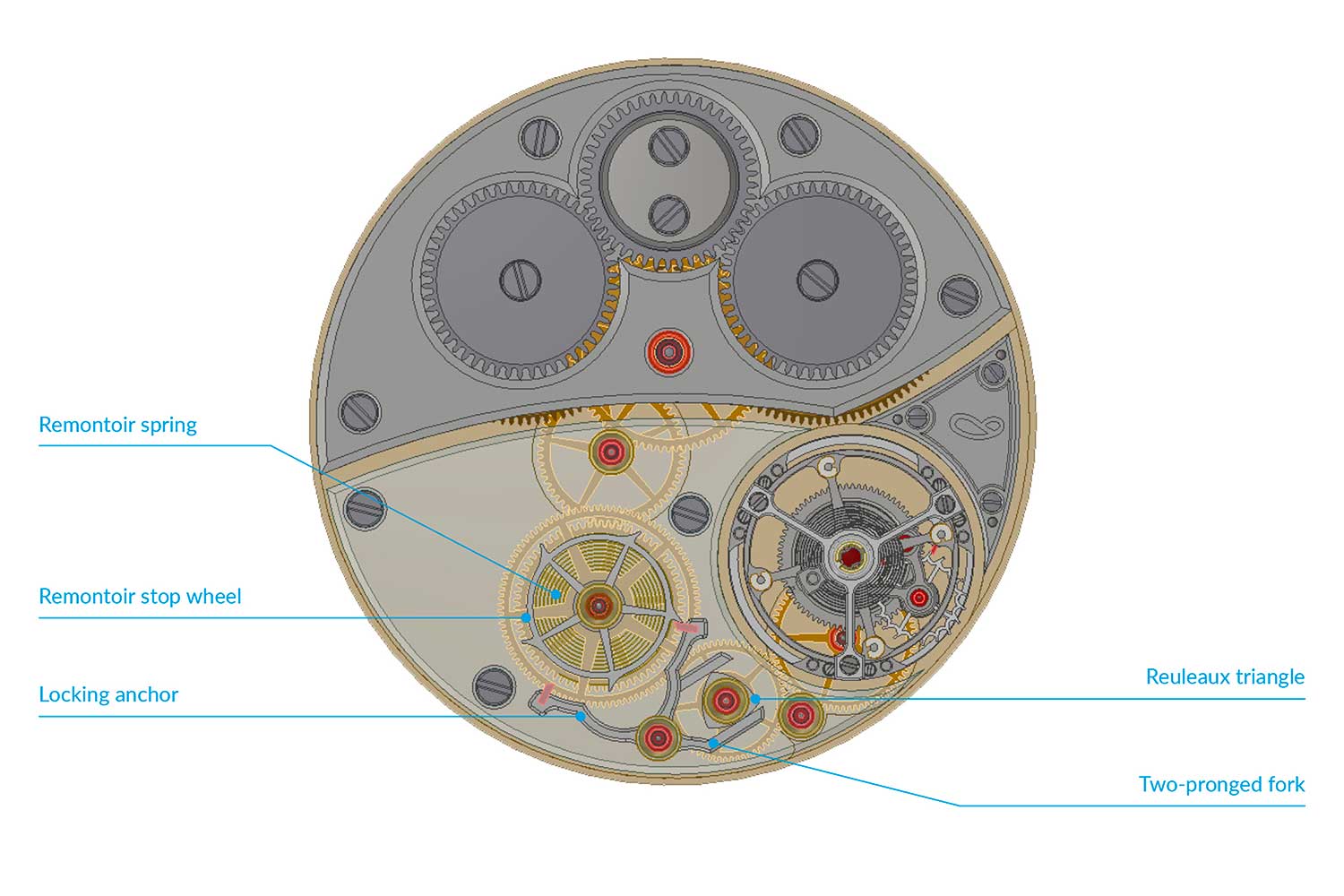

The SB08 displays the time with three discs – hours, minute units and minute tens. The discs on which the numerals are printed represent significantly more inertia compared to a simple pair of hands. Hence, ensuring the simultaneous jump of all three discs, or at least one every minute, without negatively affecting balance amplitude or overall performance, presents a genuine challenge. This is addressed with the use of a 60-second remontoir which acts as a secondary store and source of power that provides constant energy to the balance.

The digital display consists of three discs of different sizes: the hour disc in the middle, a minutes tens disc on the periphery with apertures and a minutes units disc beneath

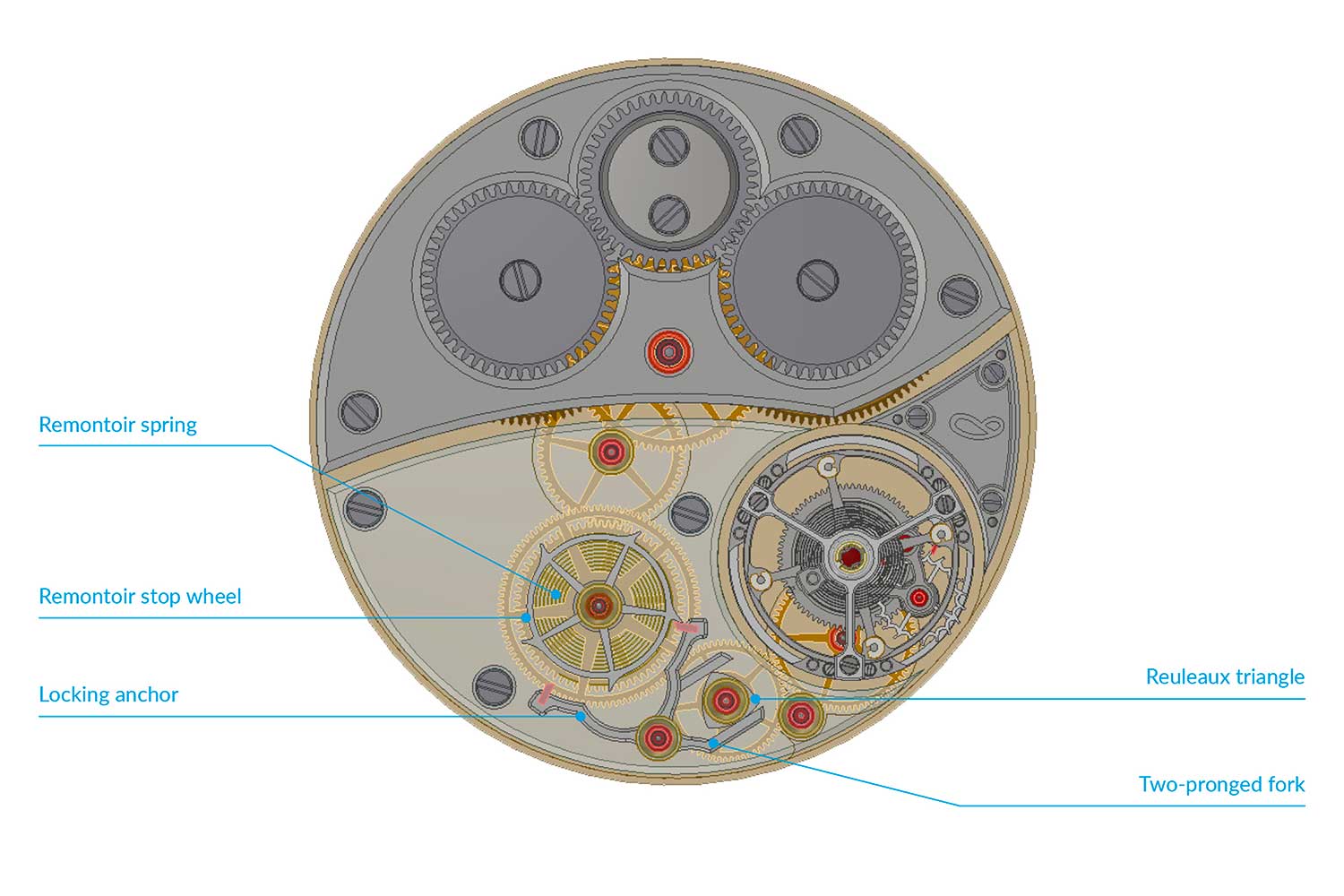

The 60-second remontoir mechanism

For the gear train to traverse the distance to the flying tourbillon, two additional wheels are incorporated into the going train and the remontoir is located on the third wheel in the gear train. The remontoir mechanism consists of a remontoir wheel, a stop wheel, a coil spring, a fork and locking anchor as well as a cam in the shape of Reuleaux triangle located on the fourth wheel.

The Reuleaux triangle revolves within a fork that moves back and forth while the triangle rotates. As the fork oscillates back and forth, the remontoir anchor, to which the fork is attached, mirrors this back-and-forth motion. As the fork moves, the anchor unlocks one of the teeth of the remontoir stop wheel. Each time the remontoir stop wheel, driven by the third wheel, snaps forward, it tensions the remontoir spring. The spring stores a full reserve of energy such that the remontoir wheel is able to drive the subsequent wheels and the flying tourbillon.

The remontoir coil spring is unusually large as it has to store sufficient energy to power all three discs as well as the tourbillon cage

While a tourbillon was invented as a genuine aid to rate stability, it simultaneously introduces additional inertia and friction. This effect becomes more pronounced as the mainspring gradually winds down, leading to a drop in balance amplitude. Thus, the remontoir also serves to overcome the weight and rotation of the tourbillon cage. As such, the remontoir coil spring is much larger than the average to handle a far greater load.

In addition to delivering constant torque, the remontoir also functions as a switching device, triggering the jump of the minute tens and hour disc. A finger cam, to which the minute unit disc is affixed, is mounted on the pivot of the remontoir wheel on the dial side. As it completes a full rotation, it advances a six-arm Maltese cross that is attached to an intermediate wheel. This intermediate wheel then drives a smaller wheel that advances the minute tens disc. As the Maltese cross completes a full rotation in an hour, a pin on the intermediate wheel advances a 12-arm Maltese cross in the centre and the hour disc attached to it leaps forward.

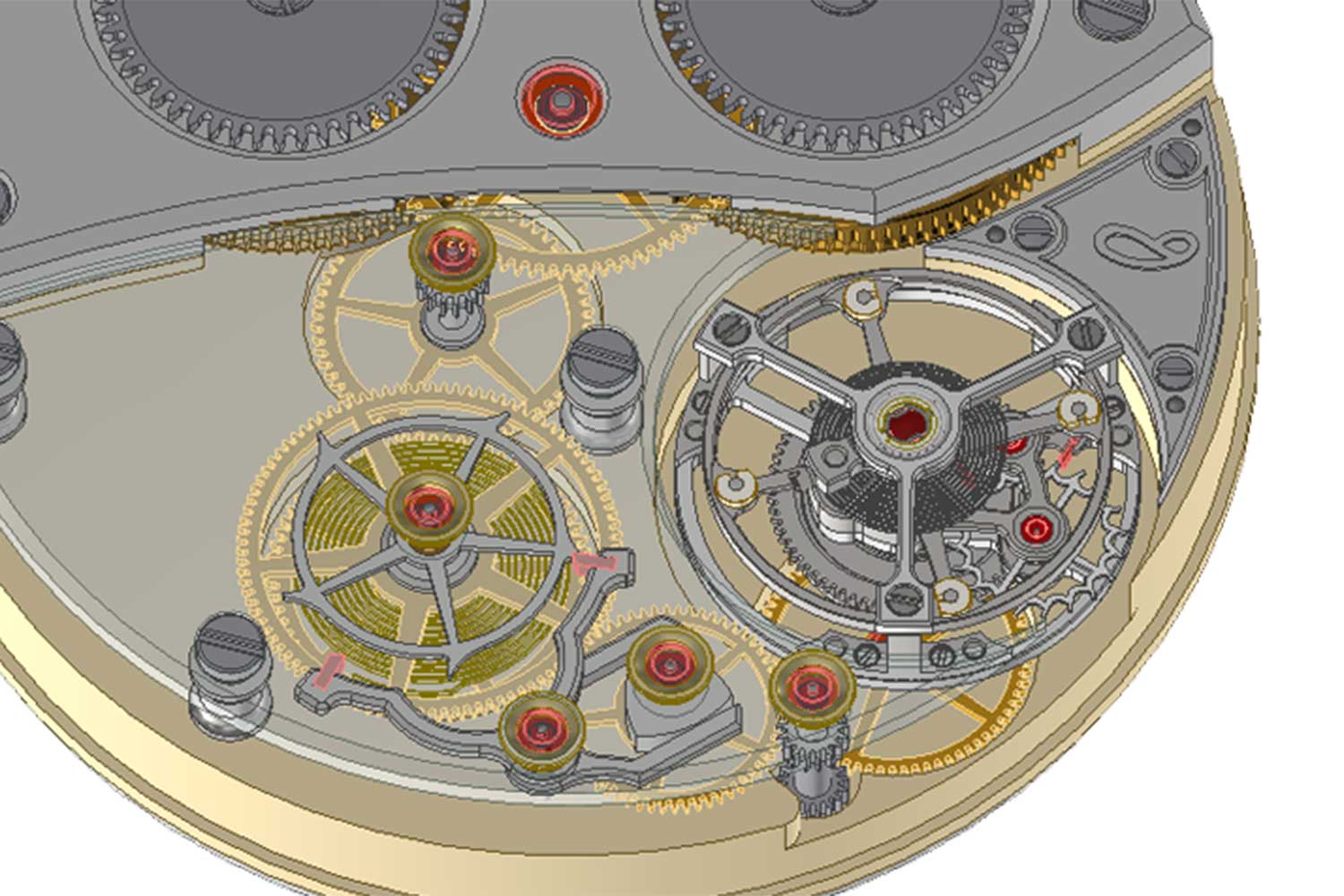

The jumping mechanism when viewed from the dial side with the base plate removed.

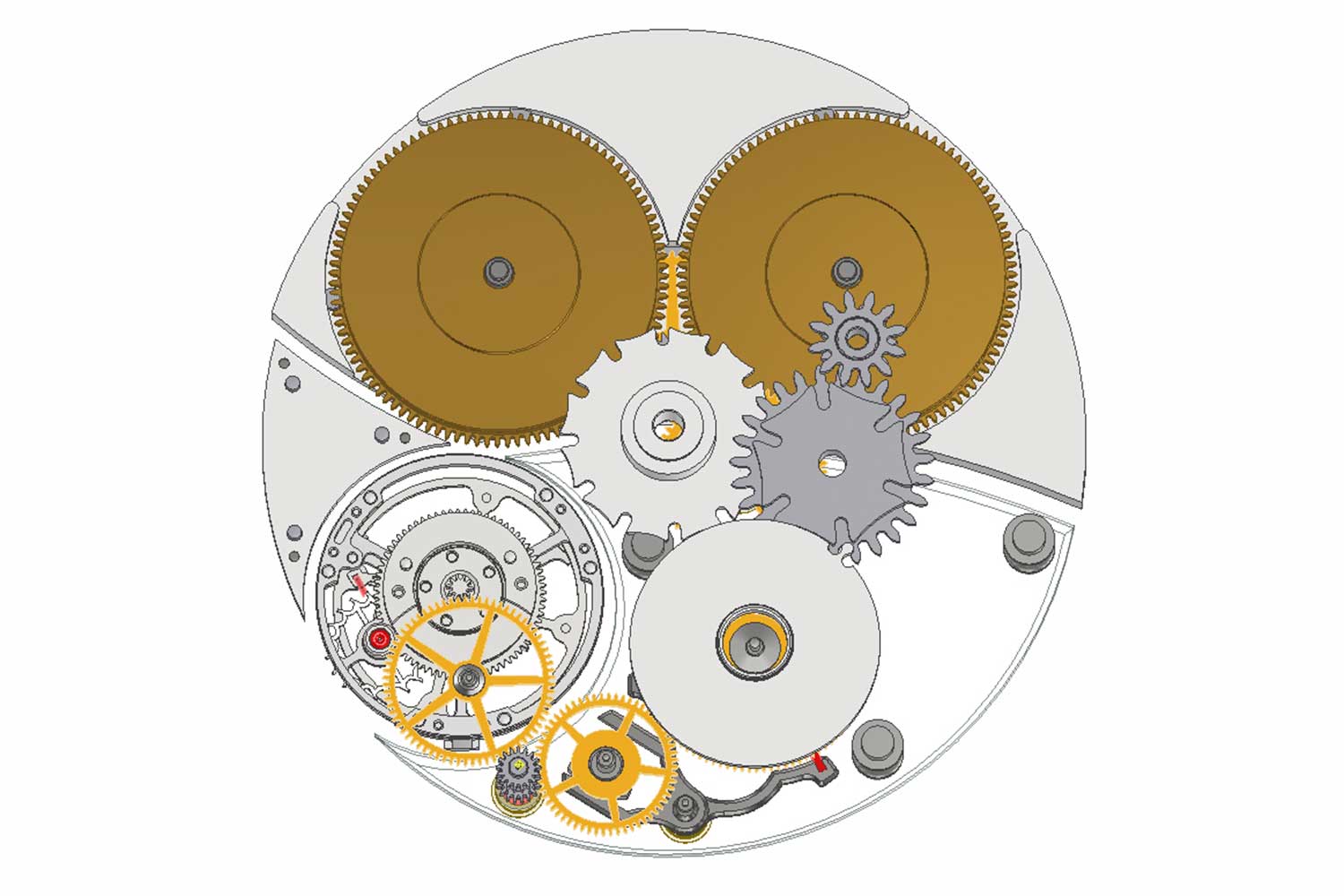

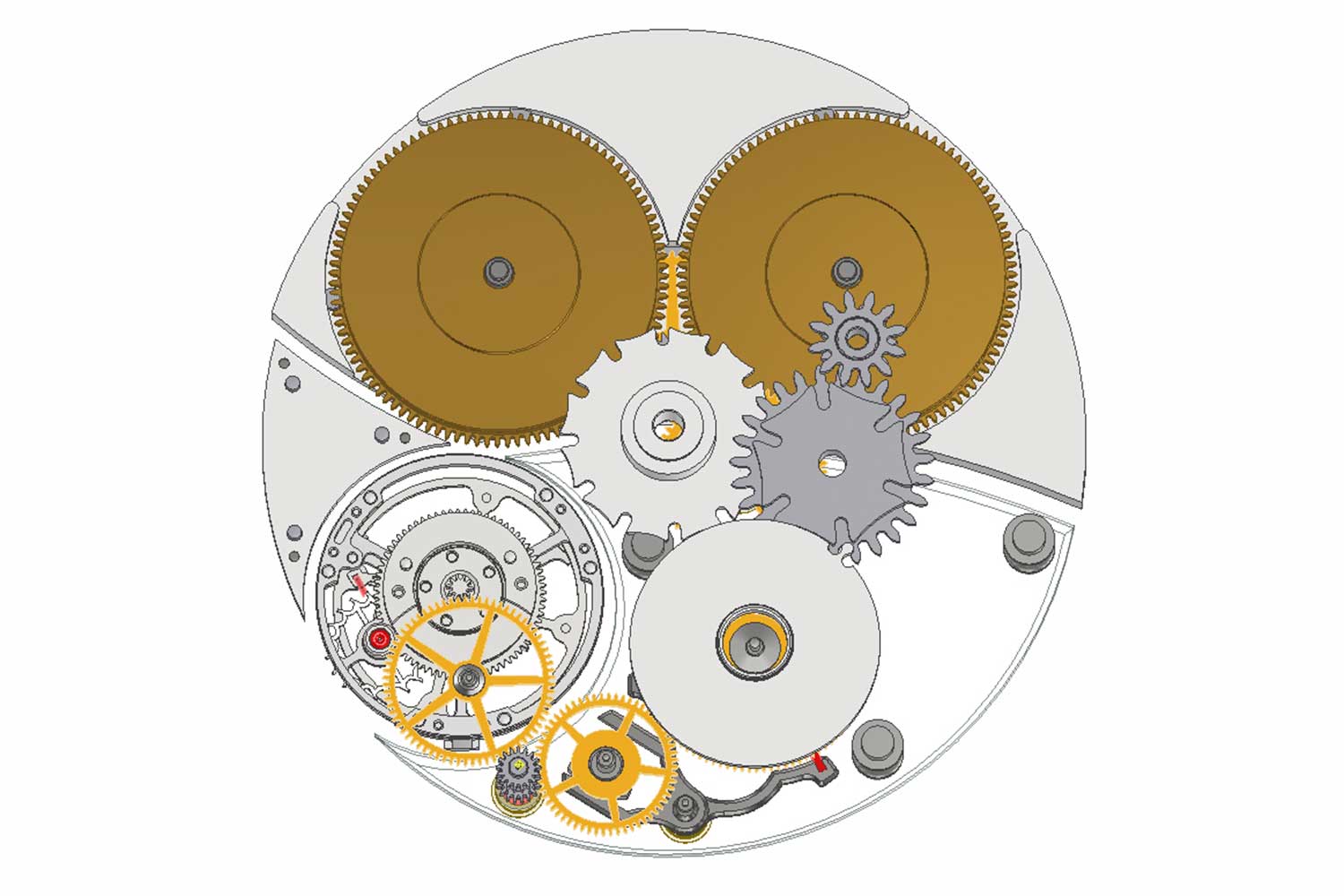

As the watch combines two power-intensive complications that are dependent on the amount of stored energy in the remontoir, the movement is designed with double barrels. Additionally, the use of two mainspring barrels allows the mainsprings to be thinner and lighter, reducing the likelihood of the coils sticking together as lubrication thickens with age. Mathieu explains that due to the lack of hands on the second gear, they have more freedom in terms of how the power source can be configured. They can either be installed in a series and unwind faster to compensate for torque demands or in parallel to increase power density. Naturally, a parallel configuration offers a more favorable balance between the number of turns and torque output.

A dial-side view of the components, with the minutes units disc mounted on the pivot of the remontoir wheel

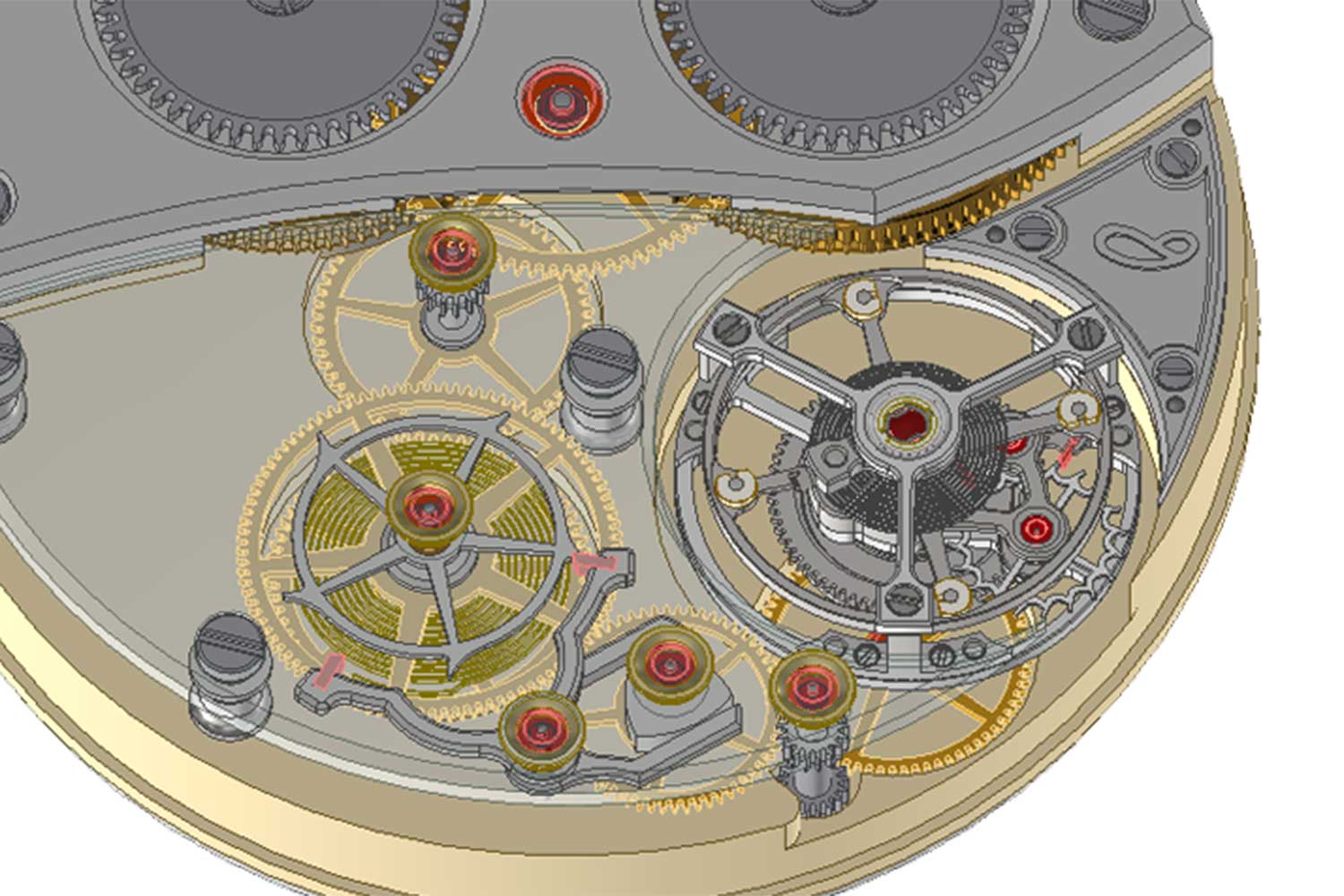

The movement was initially designed such that the crown wheel, barrels, and the first wheel in the gear train are supported by a bridge while the rest of the gear train are sandwiched between the base plate and a top plate made from sapphire crystal, which are held together by pillars. However, Mathieu has further refined the design. The first two wheels in the gear train are now supported by a sapphire top plate while the remontoir stop wheel has its own bridge, which lends itself to anglage. Below, the locking anchor, fourth wheel and pinion are held in place by a slim sapphire bridge, enabling a clear view of the remontoir mechanism in action. The base plate and barrel bridge have a frosted finish while five jewels in the movement have corresponding gold chatons. As the tourbillon is a flying tourbillon, it is only supported from below and has no upper bridge.

The latest rendering incorporates a finger bridge for the remontoir wheel that lends itself to embellishment while the rest of the gear train are supported by sapphire bridges

The case of the watch has been planned for 41mm with a thickness of 11.5mm. As these are early stages, technical details regarding the movement such as materials, power reserve, frequency and even bridge design and finishing are not finalized. If challenges arise, considering the inherent complexity in achieving the right amount of power to drive three discs of different sizes at different intervals and in different configurations, or should better ideas emerge during the process, the design remains open to modifications and improvements. The team welcomes input and feedback as they continue to refine all aspects of the watch.