A guide to Grand Seiko’s 9S family of movements, culminating in the latest 9SC5 in the Tentagraph, the brand’s first-ever mechanical chronograph.

Grand Seiko’s well-earned reputation for technical quality, innovation and foresight precedes it. In the past three years alone, it has built the wonderfully impressive Kodo Constant-Force Tourbillon (SLGT001), featuring a tourbillon and a co-axially integrated remontoir, as well as developed an impressive high performance movement, the 9SA5, bringing to market a brand-new escapement — a feat as rare in watchmaking as finding a four-leaf clover in a concrete jungle. Last year, the brand introduced the Tentagraph, its first mechanical chronograph that benefits from the exceptional foundation of the 9SA5.

Kodo Constant-Force Tourbillon (SLGT001)

Grand Seiko Tentagraph Ref. SLGC001

As the high-end expression of one of the world’s greatest watch companies, Grand Seiko embodies a philosophy rooted in crafting timepieces of impeccable quality that seamlessly blend traditional craftsmanship and cutting- edge technology. Above all, these watches stand as paragons of reliability and precision — a reflection of the Japanese industrial tradition’s relentless pursuit of refining every aspect of an object to a state of transcendent perfection.

Since Grand Seiko expanded beyond its domestic market in 2010, there has been a growing recognition that Grand Seiko watches, as evident in the quality of their cases, dials, hands and movements, give up nothing to their Swiss counterparts.

The pronounced facets of the 44GS case are Zaratsu polished

The eerily flawless diamond polished hands and indexes

Historically, the brand was the preserve of mechanical watches produced in small numbers, but today it represents the pinnacle of three distinct branches of technical accomplishment. The first is the 9F ultra high accuracy, thermo-compensated quartz movements introduced in 1993, followed by the 9R Spring Drive movement with automatic winding, unveiled in 2004 — both produced by Seiko Epson, formerly Suwa Seikōsha. The third is the 9S mechanical movement by Seiko Instruments, formerly Daini Seikōsha, engineered to rival the very best of Swiss watchmaking. While all three groups of movements exemplify a level of finesse and care in construction that is worthy of equal admiration, our attention today will be directed toward the 9S family of movements as they celebrate their 25th anniversary this year.

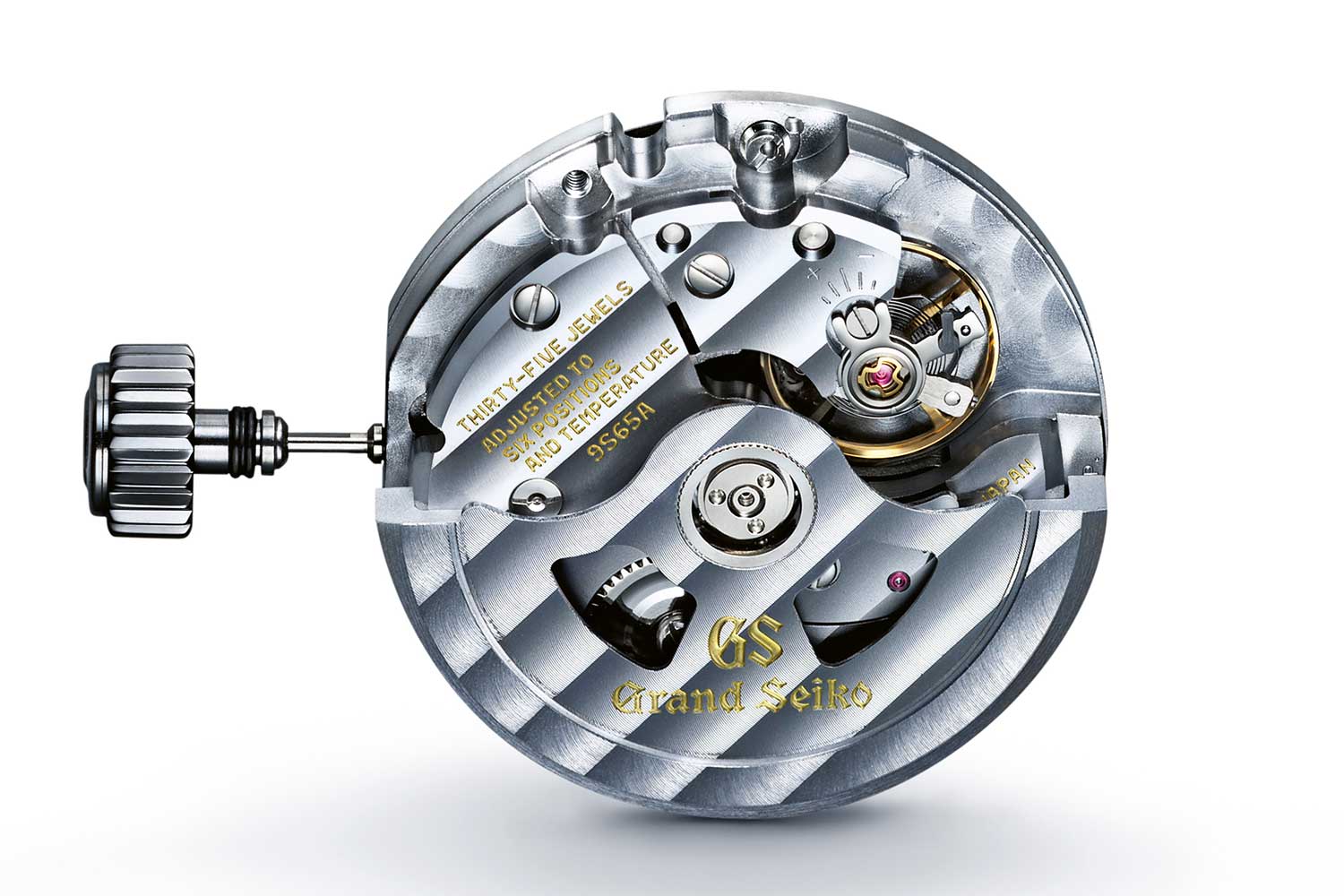

A new beginning: The 9S55 and 9S65

In 1998, the introduction of the caliber 9S at the Shizukuishi Watch Studio in Iwate prefecture represented Grand Seiko’s first mechanical movement since 1976, marking the rebirth of mechanical watchmaking at the brand. It was also that year where Grand Seiko updated the now famous “Grand Seiko Standard” of a mean daily rate of between -3/+5 seconds, initially established in 1966. All 9S calibers today undergo an extensive 17-day testing process, evaluated in six positions — surpassing the standard set by the dominant industry testing body, the Contrôle Officiel Suisse des Chronomètres (COSC), which is a 15-day examination and in five positions. Likewise, temperature assessments are more demanding, requiring movements to achieve superior accuracy levels of ±0.5 seconds per day per degree Celsius within specific temperature ranges (between 8°C and 23°C, and between 23°C and 38°C), compared to the COSC’s ±0.6 seconds per day per degree Celsius standard.

Right from the outset, the 9S family of movements were intended to compete in terms of performance and finishing with the best mass-produced automatic movements on the market, such as those of Rolex and Patek Philippe. It was the first movement family to benefit from Computer-Aided Design (CAD) and Computer-Aided Manufacturing (CAM) technology. CAD software allowed engineers and designers to create detailed virtual models of movements and gear profiles, while CAM software assisted in turning those designs into physical prototypes or finished parts by controlling machining tools and processes. These systems helped optimize the product development cycle, improving precision, efficiency, and accuracy in manufacturing while making genuine improvements from previous movement designs.

The first generation of 9S5X calibers launched in 1998 was designed to provide a beat rate of 28,800 vibrations per hour while delivering an extended power reserve of 50 hours, surpassing the standard 45 to 48 hours found in a majority of movements on the market at that time. It differed on a fundamental level from the 5600 and 5200 family of calibers, which powered the Lord Matic, King Seiko and Grand Seiko watches until 1976, as it was designed with a directly driven central seconds, with the fourth wheel located in the center of the movement — an indication that it was built from the ground up as a modern caliber. It was also equipped with automatic bi-directional winding via Seiko’s patented Magic Lever system which boasts a simplicity in design that contributes to its overall robustness.

The 9S caliber was initially introduced in two versions: the time-only 9S51 and the 9S55 with date. A manual winding version, the 9S54, was introduced in 2001 followed by a GMT version, the 9S56, in 2002. In 2010, Grand Seiko made significant improvements to the caliber, notably increasing its power reserve to 72 hours, resulting in the 9S65. The fundamental gear train arrangement remains identical to its predecessor, with a directly driven central seconds. However, the escape wheel and pallet fork are fabricated using the microelectromechanical systems (MEMS) process known as LIGA, the German acronym for Lithographie, Galvanoformung, Abformung (“lithography, electroplating, molding”), an additive microelectromechanical technique that allows for extreme precision and intricate shapes. The resulting escapement is made up of parts skeletonized to minimize inertia.

Grand Seiko SBGR001 with calibre 9S55 (Image: eBay)

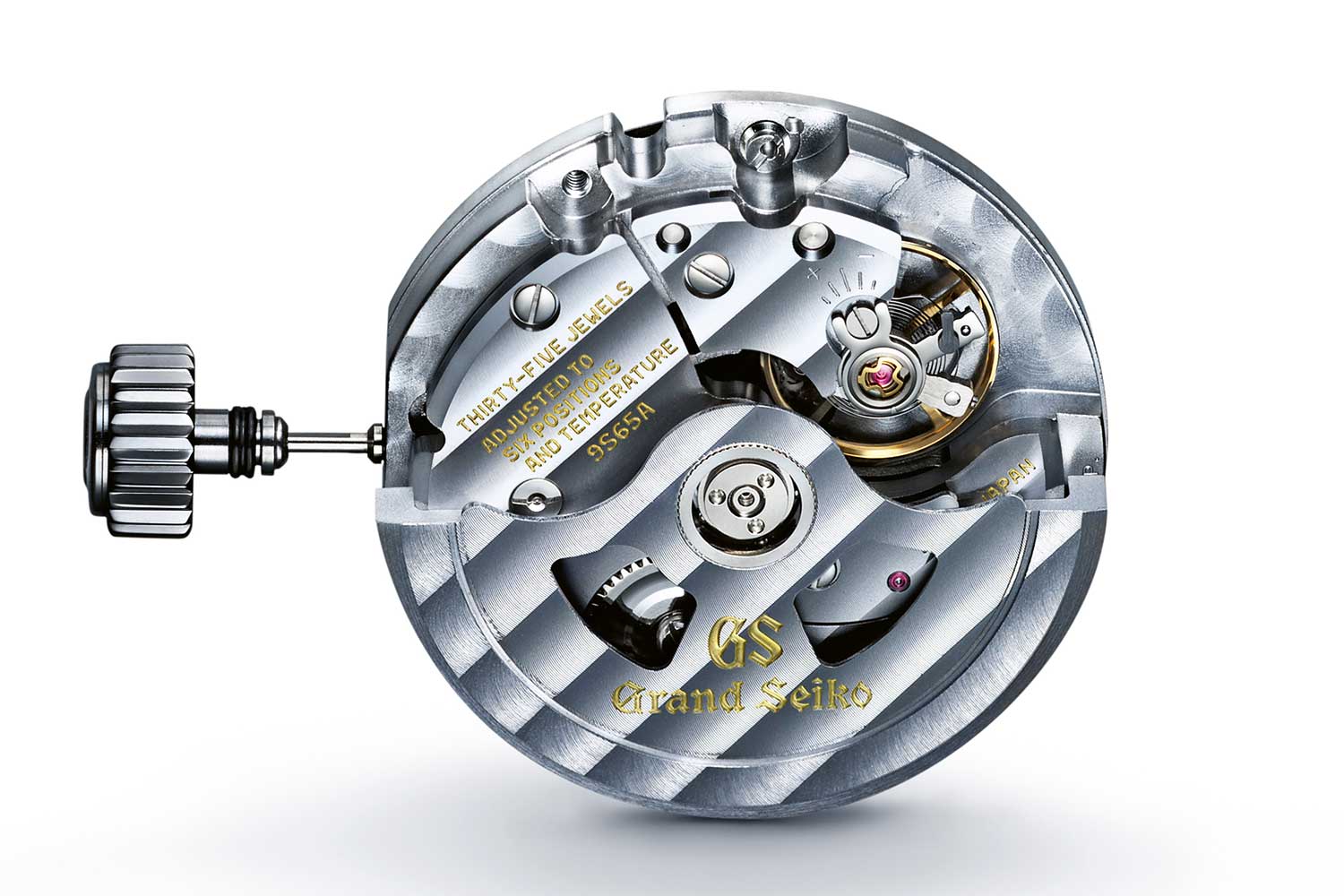

Caliber 9S65

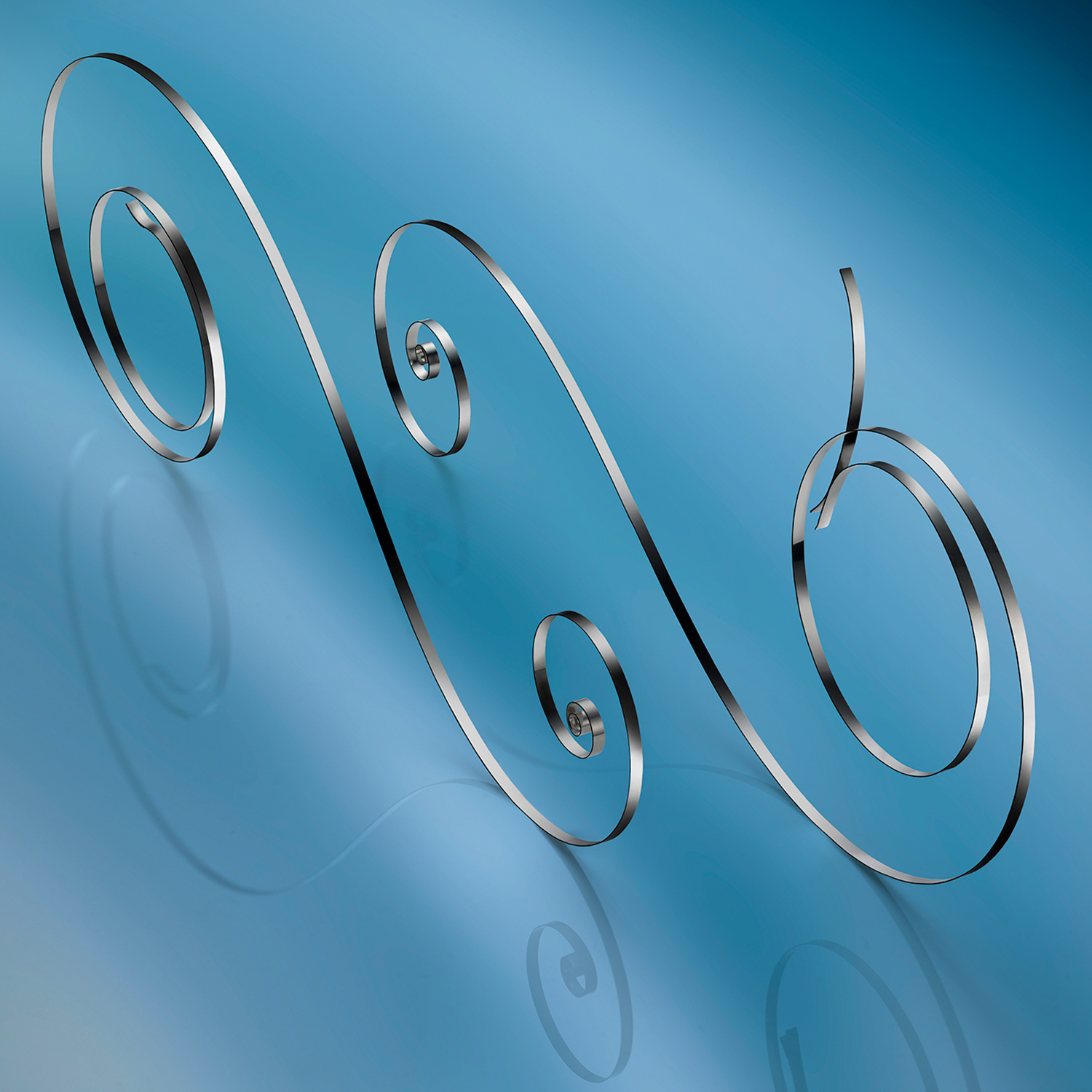

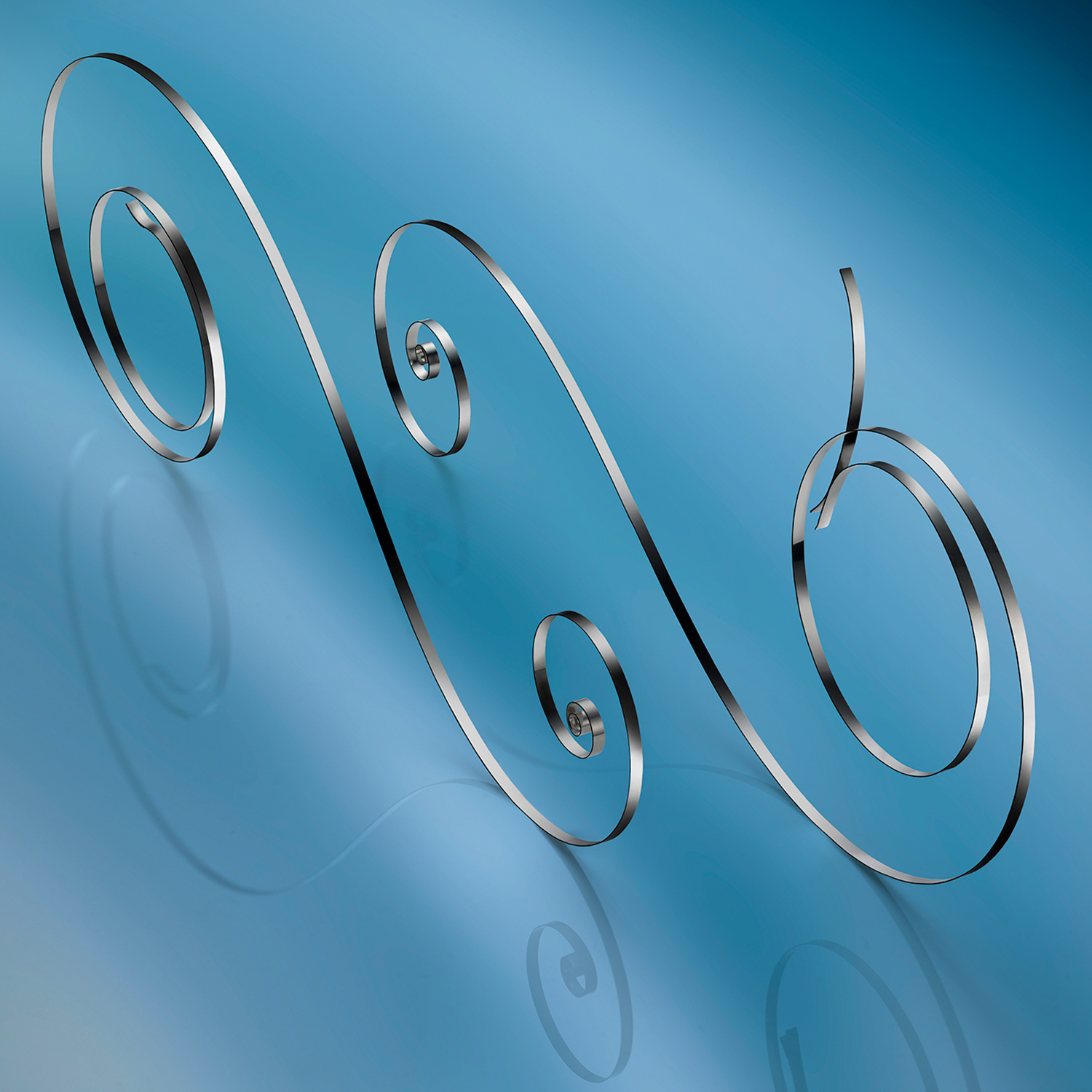

The significance of the escape wheel’s inertia lies in its positioning at the end of the gear train. It is therefore the fastest wheel in the movement and also the one with the least torque, being the furthest away from the mainspring. Its inertia is multiplied by the number of turns it has to make for every revolution of the fourth wheel. Thus, despite its typically lightweight and small size, the escape wheel’s inertia exerts the most influence among all the wheels in the going train. As such, reducing its inertia plays a huge role in extending its power reserve to 72 hours. In addition, both the mainspring and hairspring utilize an advanced series of Spron alloys — the Spron 610, composed of iron, nickel, chromium, cobalt, niobium and titanium. It exhibits increased strength and hardness, along with an exceptional resistance to magnetism, corrosion and temperature fluctuations, essentially sharing similar properties to silicon without the brittleness. Its high elasticity also ensures it does not deform easily and therefore maintains its mechanical properties and performance over extended use.

The 610 Spron mainspring offers greater strength and resistance to magnetism, temperature fluctuations and corrosion

While its predecessor used Seiko’s Magic Lever mechanism, the caliber 9S65 employs a reverser gear train, which has less play or backlash. Pawls and ratchet wheel, compared to precisely meshed gear teeth in regular gears, could contribute to minor energy losses through increased friction or less direct power transfer. Reversers sit on posts so the alignment of teeth between each reverser wheel is fixed and better engaged. Additionally, the reverser mechanism is made up of hardened components to increase its strength, durability and resistance to wear.

Grand Seiko has since filled out an entire family of movements around the 9S65, which includes the automatic 9S66 GMT version, the manual winding 9S64 as well as the manual winding 9S63 with indirectly driven small seconds.

Caliber 9S64

In pursuit of precision: The 9S85

During the Swiss timing trials of the 1960s, Suwa Seikōsha and Daini Seikōsha learned that higher frequency movements were unquestionably superior in maintaining a stable rate. After Seiko’s sweeping victories led to the termination of observatory competitions in 1968, both began introducing Grand Seiko watches with a vibration period of one tenth of a second, that is 36,000 vibrations per hour, which is a useful improvement in daily rate stability, particularly for a wristwatch.

In 2009, Grand Seiko reintroduced high frequency mechanical movements in the form of the 9S85. Compared to the first generation 9S5X series, the Hi-Beat caliber 9S85 not only raised its beat rate to 36,000vph, but notably also extended its power reserve to 55 hours. This was achieved by increasing the diameter of the movement from 25.6mm to 28.4mm, enabling it to accommodate a larger mainspring barrel. Additionally, like the 9S65, the springs at the extreme ends of the wheel train utilize the Spron 610 alloy, which is highly resistant to breakage, strain-induced fatigue and temperature fluctuations. It is nonmagnetic and due to its strength and hardness, offers an even power delivery throughout the course of its power reserve.

An example of classic Grand Seiko watchmaking, the Hi-Beat Calibre 9S85 is a strong and precise movement, designed for longevity

Fundamentally, an increase in frequency, and therefore the angular velocity of the balance, results in an oscillator that is less susceptible to external disturbances. However, a high speed escapement demands greater energy and results in greater friction and wear on the components, essentially causing lubricants to run out faster, which would necessitate more frequent servicing. To mitigate this, both the escape wheel and pallet fork are fabricated using LIGA. The resulting escapement consists of lightweight, corrosion resistant, and nonmagnetic skeletonized components made from nickel-phosphorus. The new escape wheel design also features oil reservoirs at the tip of each gear tooth to improve oil retention. Furthermore, to minimize friction on the pivots in the gear train, an additional wheel was introduced between the fourth wheel and escape wheel to distribute the load. The 9S85 also employs a standard modern reserver system instead of the Magic Lever mechanism to improve transmission efficiency and reduce energy loss.

The nickel-phosphorus escapement produced via LIGA is made up of skeletonised parts to reduce inertia while also having recesses in the escape wheel teeth for oil retention

A triumph in performance: The 9SA5

In 2020, Grand Seiko unleashed a horological tour de force with the debut of the Hi-Beat 9SA5 movement equipped with a brand-new escapement. In keeping with Grand Seiko’s generally unassuming approach to product names, it is simply called the Dual Impulse escapement.

The Caliber 9SA5, a triumph both aesthetically and mechanically

In watchmaking today, almost all wristwatch escapements, excluding the detent escapement, fall under the category of dual impulse escapements which refers to their ability to deliver two impulses to the balance wheel at each cycle — one at each vibration. This characteristic is pivotal in the development of a modern and practical escapement capable of withstanding external perturbations effectively in a wristwatch.

However, the main difference between each of these dual impulse escapements lies in the way power is delivered to the balance wheel. The main purpose of an escapement is to regulate the discharge of energy by the mainspring, resulting in the turning of the hands, as well as to transmit energy to the balance wheel. In turn, the escape wheel is released and therefore controlled by the oscillation of the balance wheel, which sets a standard for accuracy. The lever escapement has enjoyed an unparalleled dominance in watchmaking since it was invented around 1755 by Englishman Thomas Mudge. It is particularly suited for wristwatches due to its ability to provide two impulses per cycle and self-start, along with its solidity and high degree of detachment, meaning, unlike earlier escapements such as the verge or cylinder escapement, the escape wheel locks free of the balance after delivering energy through the impulse jewel, leaving the balance free during all of its supplementary arc of travel.

However, despite its excellent performance in the short term, its primary flaw that plagued the most genius minds in the annals of horology is its need for lubrication. Both impulses are transmitted indirectly via a lever, which is in turn propelled by the force of the escape wheel teeth contacting the pallet jewels of the lever. The pallet jewels momentarily stop the escape wheel’s rotation and then release it, imparting energy to the balance wheel through the pallet fork. The sliding interaction between the pallet jewels and the escape wheel teeth is essential for controlling the release of energy and regulating the movement of the gear train. However, this sliding action generates friction between these components, making the surfaces vulnerable to wear and tear, rendering lubrication crucial. The inevitable deterioration of an applied lubricant, in turn, has adverse effects on accuracy.

As such, the detent escapement, also known as the chronometer escapement, remained preferred for specialized applications like marine chronometers due to their oil-free operation and direct impulse, offering exceptional accuracy in stationary or controlled environments. However, the primary setback preventing the use of detent escapements in wristwatches is that, unlike the lever escapement, impulse is provided in a single direction — once per oscillation. This design trait renders the detent escapement non-self-starting. In the event the balance is stopped — whether inadvertently or deliberately — the detent escapement cannot resume without assistance, requiring gentle shaking to restart the balance’s oscillation. Furthermore, the delicate detent that locks the escape wheel is prone to disruption by shocks, potentially causing premature unlocking of the escape wheel.

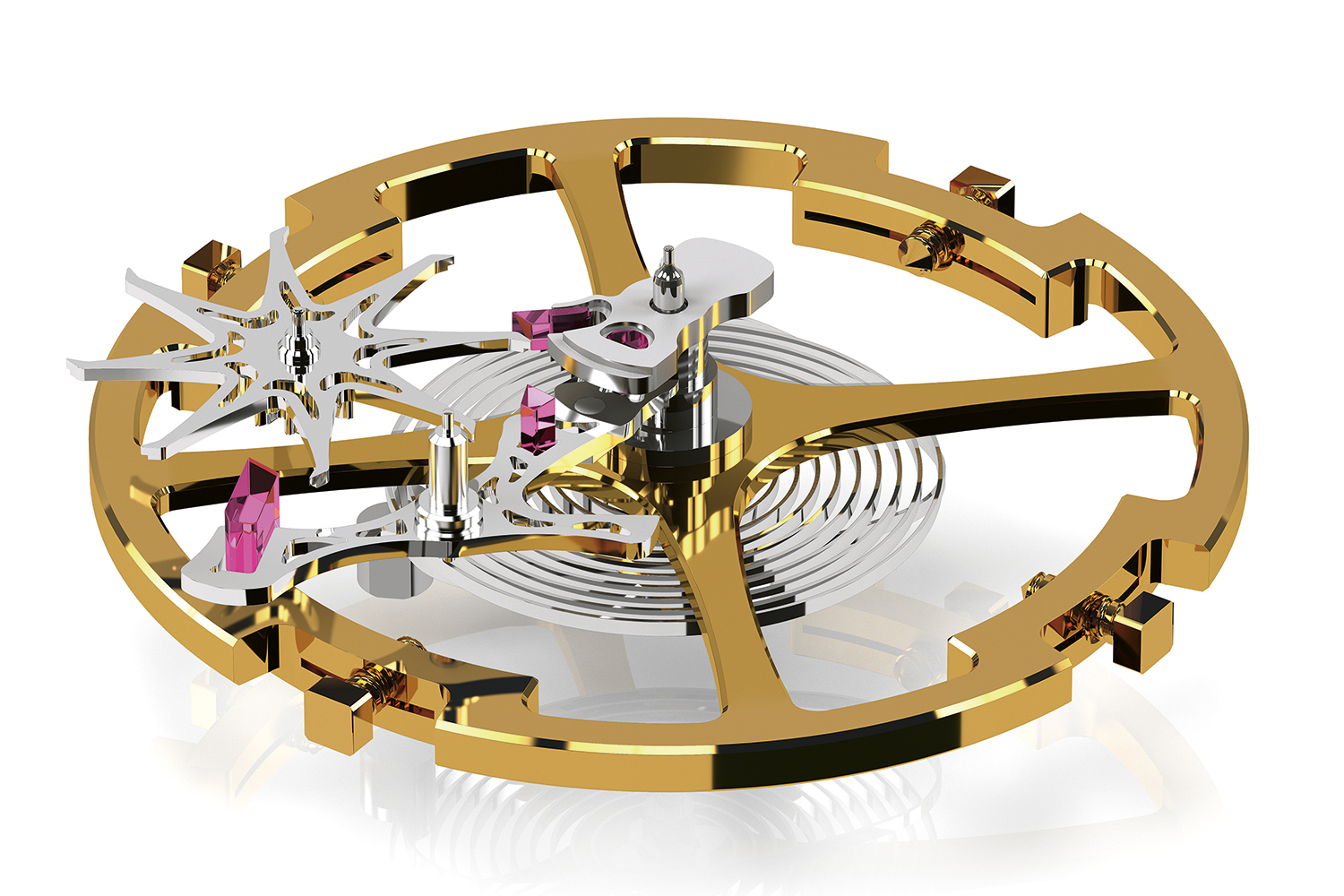

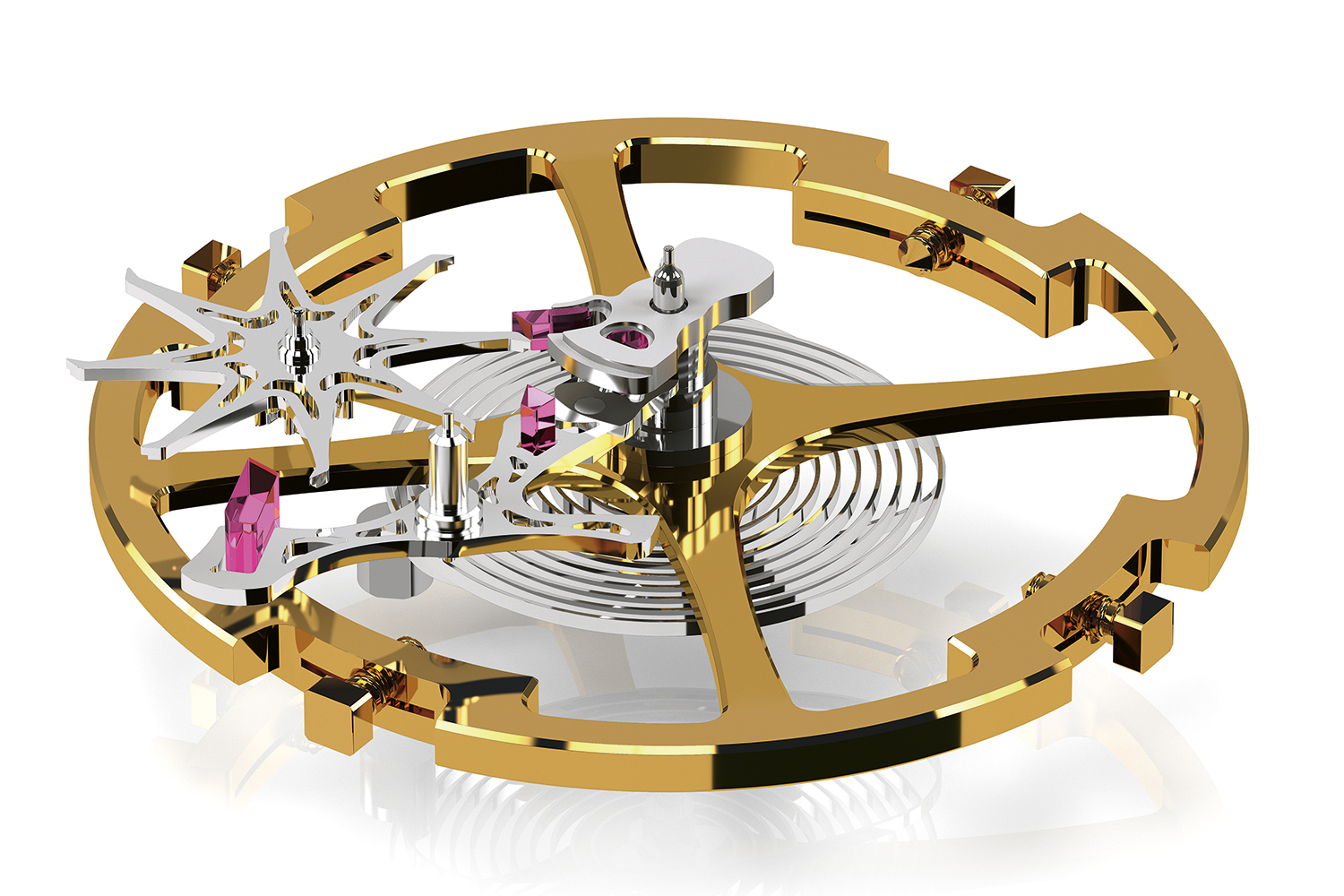

The Dual Impulse Escapement

Hence, many alternative escapements in the market today serve to combine the direct impulse delivery of the detent escapement and the robustness and self-starting ability of the lever escapement. But to dethrone the lever escapement, the design of the new escapement ultimately requires a level of maturity and adaptability to industrial production on top of offering the additional advantage of the elimination or reduction of oil, making such an endeavor an uphill battle that, when conquered, earns its spot in the horological hall of fame.

The only alternative escapement that has been successfully realized on an industrial scale is the Co-Axial escapement invented by George Daniels in 1976, more than two centuries after the invention of the lever escapement. The Co-Axial met all the criteria of a modern, practical escapement. It delivers two impulses to the balance at each cycle, is self-starting and free from the need for lubrication. However, its drawback lies in its somewhat delicate construction, necessitating a pair of co-axially mounted escape wheels which increases inertia and demands care in adjustment to ensure concentricity.

Grand Seiko’s Dual Impulse escapement shares similar qualities to both the Swiss lever as well as the Co-Axial. Like both escapements, the Dual Impulse escapement provides two impulses per cycle — one at each vibration — making it resistant to shocks. But while the lever escapement provides two impulses indirectly via a lever, both the Co-Axial and the Dual Impulse escapement adopts a mixed impulse system: one impulse is given directly to the balance wheel, while the other is delivered indirectly through a lever. This setup therefore suggests that the quality of both impulses might potentially vary, although this is more abstract than a real-life problem.

In this regard, it is impossible to overlook the independent double-wheel escapement, developed by George Daniels as a solution to the natural escapement that eluded Breguet. It is theoretically superior as two escape wheels impulse the balance in opposite directions directly at each cycle, making its power delivery extremely efficient. However, the basic principles of this system, where each escape wheel necessitates its own gear train, proved limiting to the design of the movement as a whole, and the complexity of its construction makes it impossible to industrialize.

While the Co-Axial and Dual Impulse escapements share a fundamental similarity in that one impulse is given directly, their distinction lies in the method of indirect delivery. The Co-Axial employs radial impulse and therefore does not require lubrication. Conversely, the Dual Impulse escapement utilizes a familiar sliding action to deliver impulse to the lever. This reintroduces the need for lubrication, albeit minimal — half that of the Swiss lever. In other words, it offers far greater efficiency compared to the Swiss lever, while being simpler and less finicky than the Co-Axial, requiring just one escape wheel.

Crucially, the Dual Impulse escapement was also designed to operate with low inertia. The pallet fork and lever are produced using LIGA, allowing components to be fabricated with extreme precision, resulting in its intricate, skeletonized geometries that are lighter to ensure quicker acceleration of parts, which is more crucial in a high-beat movement.

The performance gains in the low-inertia, low-friction Dual Impulse escapement translate to a longer power reserve as well as a high beat rate of 36,000vph in the caliber 9SA5 — properties that vary inversely and are rarely found in the same movement. The oscillator also represents several firsts for Grand Seiko — the balance wheel is free sprung, secured on both ends by a balance bridge for greater stability, and is attached to an overcoil hairspring with a proprietary curve developed through over 80,000 computer simulations.

The rest of the movement was designed with a great sense of purpose and logic. Overall, it is slightly wider than the 9S85 to accommodate a pair of serially coupled barrels while being 15 percent slimmer at just 5.18mm high. This is achieved with thinner mainsprings. With a highly efficient escapement, the strength of the mainspring can be reduced to lessen the load and wear on the pivots and wheels, thereby extending service intervals and reducing running costs for the wearer. Additionally, the serially coupled barrels are directly geared to each other as opposed to being connected via an additional wheel, further reducing inertia.

Mainsprings

Twin Barrels

It also features an unusual horizontal gear train arrangement. The gear train consists of five wheels instead of three as the escape wheel has fewer teeth. As such, it is the fifth wheel that drives the centrals seconds directly. Rather than increasing the number of teeth on the escape wheel to achieve a higher beat, two additional wheels were added to distribute the load across more wheels, mitigating wear on the pivots and wheels. Typically, in a movement with serially coupled barrels, the second wheel, which drives the minutes, is located in the middle, overlapping the barrel. But to reduce the height of the movement, the barrel drives a second wheel located on the right of the movement when viewed from the caseback. It is solid rather than spoked for rigidity as it has the greatest load to bear. Beyond that, the design of the movement is as visually attractive as it is remarkably efficient, with a total of four beautifully shaped bridges as well as a skeletonized rotor, allowing the components to be admired. It is also equipped with an instantaneous date-changing mechanism, which switches over in under a second at midnight. All told, the 9SA5 is one of the most sophisticated and impressive automatic movements on the market, offering the exceptionally rare combination of a lengthy power reserve and a high frequency.

Horizontal gear train

The first mechanical chronograph movement: The 9SC5

To the delight of many Grand Seiko devotees this year, the brand introduced its first-ever mechanical chronograph, the Tentagraph (SLGC001). While Grand Seiko has produced chronographs in the past, they were all equipped with Spring Drive movements, demonstrating its penchant for high accuracy chronographs. Given that activating the chronograph would lead to a decrease in balance amplitude, the high performance 9SA5 was perhaps the only worthy base movement in the eyes of Grand Seiko.

Grand Seiko Tentagraph Ref. SLGC001

In the Tentagraph’s 9SC5 movement, the chronograph was built on the superb 9SA5, thereby making it an automatic high frequency chronograph. This means that the 9SC5 movement has a modular construction, where the chronograph plate is located between the calendar plate and the mainplate. While modular chronographs are frequently discussed with less enthusiasm than integrated ones, it is worth keeping in mind that they are often a result of the successful development of a top-tier base movement, which certainly holds true in this instance.

The construction of the chronograph module relies on several tried-and-true approaches characteristic of Grand Seiko’s chronographs. It is governed by a column wheel and relies on a vertical coupling system. It bears remembering that while the El Primero took the lion’s share of attention in the three-way contest to build the world’s first automatic chronograph in 1969, the Seiko 6139 Speedtimer by Suwa Seikōsha was the first column-wheel automatic chronograph to incorporate a vertical clutch. It is arguably the most influential among movement builders despite it being the least known of the three among the general public.

The chronograph module employs a column wheel and a vertical clutch (located next to the chronograph seconds wheel)

The vertical clutch in the 9SC5 comprising of two co- axial intermediate wheels is located slightly off the central axis of the movement. One intermediate wheel is constantly driven by a central extension wheel from the fourth wheel. When the chronograph is activated, two coupling levers releases the clutch, which drives the chronograph seconds wheel, enabling it to rotate together with the extension wheel. Among the other hallmark approaches is the use of a single, integrated three-point reset hammer that zeros all three counters — the chronograph seconds, minutes and hours — at once.

In contrast to the 80-hour power reserve of the 9SA5, the 9SC5 has a power reserve of 72 hours with the chronograph disengaged. This difference arises from the need for an auxiliary train to transfer the central seconds output from the base movement to the running seconds counter positioned at three o’clock. With that said, 72 hours puts it on par with some of the top automatic chronographs on the market while making it the lengthiest among high frequency chronographs. Undoubtedly, this can be attributed to the incredibly efficient Dual Impulse escapement as well as the use of double barrels.

Cased up, the Tentagraph measures 43.2mm wide and 15.3mm high due to the nature of its construction. While it is definitely a large, eye-catching timepiece, it wears comfortably as the case and bracelet are made from the brand’s proprietary high intensity titanium, which is said to be 30 percent lighter and more scratch resistant than stainless steel. The case design incorporates multiple intersecting planes, alternating between satin-brushing and the renowned Zaratsu polish. The tachymeter bezel, on the other hand, is made of ceramic, making it scratch resistant.

The titanium case has multiple facets, alternating between satin-brushing and the renowned Zaratsu polish

The impressive dimensions are further enhanced by the striking dial architecture. It features wide, grooved and faceted indexes, offering outstanding legibility, along with dramatic dauphine hands, with a pronounced tapering towards the tips. Both are filled with Seiko’s proprietary LumiBrite, a phosphorescent compound that boasts a brighter and longer lasting glow compared to Super- LumiNova, the standard luminous paint used on most watch dials. The subdials for the counters are deeply recessed and are actually separate inserts, further adding depth to the dial, while their respective hands feature a polished bevel on their hubs. The beautiful dial texture was inspired by the ridges of Mount Iwate, which is visible from the Grand Seiko Studio Shizukuishi, while the rich shade of blue is inspired by the night sky.

The utterly luxurious, elaborately crafted dial with inlaid sub-dials, faceted and grooved indexes, and a distinctive handset

Ultimately, the Tentagraph is a continuum of what Grand Seiko does best, which is to deliver watches that are nuanced and supremely beautiful on the outside while maintaining unquestionable precision and reliability on the inside. Only in this case it boasts the brand’s crowning achievement — the Dual Impulse escapement — which when viewed within the field of chronographs, makes it the only high frequency chronograph with an exotic escapement and also the only chronograph with both a high frequency and long power reserve. As a first outing, it’s pretty neat.

The superb base caliber with four beautifully shaped bridges visible through the sapphire case back

Grand Seiko Tentagraph Ref. SLGC001Movement: Self-winding caliber 9SC5; 72-hour power reserve

Functions: Hours, minutes, small seconds, chronograph and date

Case: 43.2mm; high intensity titanium with black ceramic bezel; water resistant to 100m

Dial: Blue with “Mt. Iwate” pattern; applied faceted and ridged indexes with LumiBrite coating

Strap: High-intensity titanium bracelet

Price: SGD 19,000