A double balance and differential watch with a highly inventive construction.

The watch most renowned for its use of double balances and a differential is none other than the Philippe Dufour Duality. The Duality was launched in 1996 and it was the first wristwatch to incorporate double balances of any setup known today. In contrast to a resonance watch, which incorporates two separate gear trains and balances to improve rate stability through an exchange of energy, the principle behind a differential setup is to attain an averaged and therefore improved rate. When two balance wheels oscillate at slightly different rates, the differential balances out their rate difference.

The Duality has a beautifully simple architecture, where the wheel train is arranged diagonally across the base plate, with the small seconds display directly powered by the differential on the fourth wheel. As such, this configuration leads to the asymmetrical placement of the small seconds subdial at seven o’clock on the dial. However, what if the brief changes a little and it becomes necessary to preserve a symmetrical layout of the balances while also incorporating a seconds indicator?

This task is a lot less straightforward than one might initially grasp, as each objective imposes limitations on the other and on all other aspects of the movement. Hence, most watches of this nature are designed one without the other. While maintaining the crown at the conventional three o’clock position, placing the differential on the fourth wheel leads to an asymmetrical outcome. However, if the differential is positioned on the second or third wheel, it requires an indirect drive seconds indicator as the fourth wheel(s) will not yield an averaged output.

The Czapek Place Vendôme Complicité accomplished both aspects in the most unusual and intriguing way. Recently introduced, the watch was a result of a collaboration between Czapek and Bernhard Lederer. The fact that it took no less than Bernhard Lederer says enough of its complexity. In fact, Xavier de Roquemaural, the CEO of Czapek had a more complex set of directives, envisioning that the balance wheels be placed at 4.30 and 7.30 on the watch face and the differential at 12 o’clock to mirror the design of the brand’s foundational Place Vendôme model, which featured sub-dials in those exact locations.

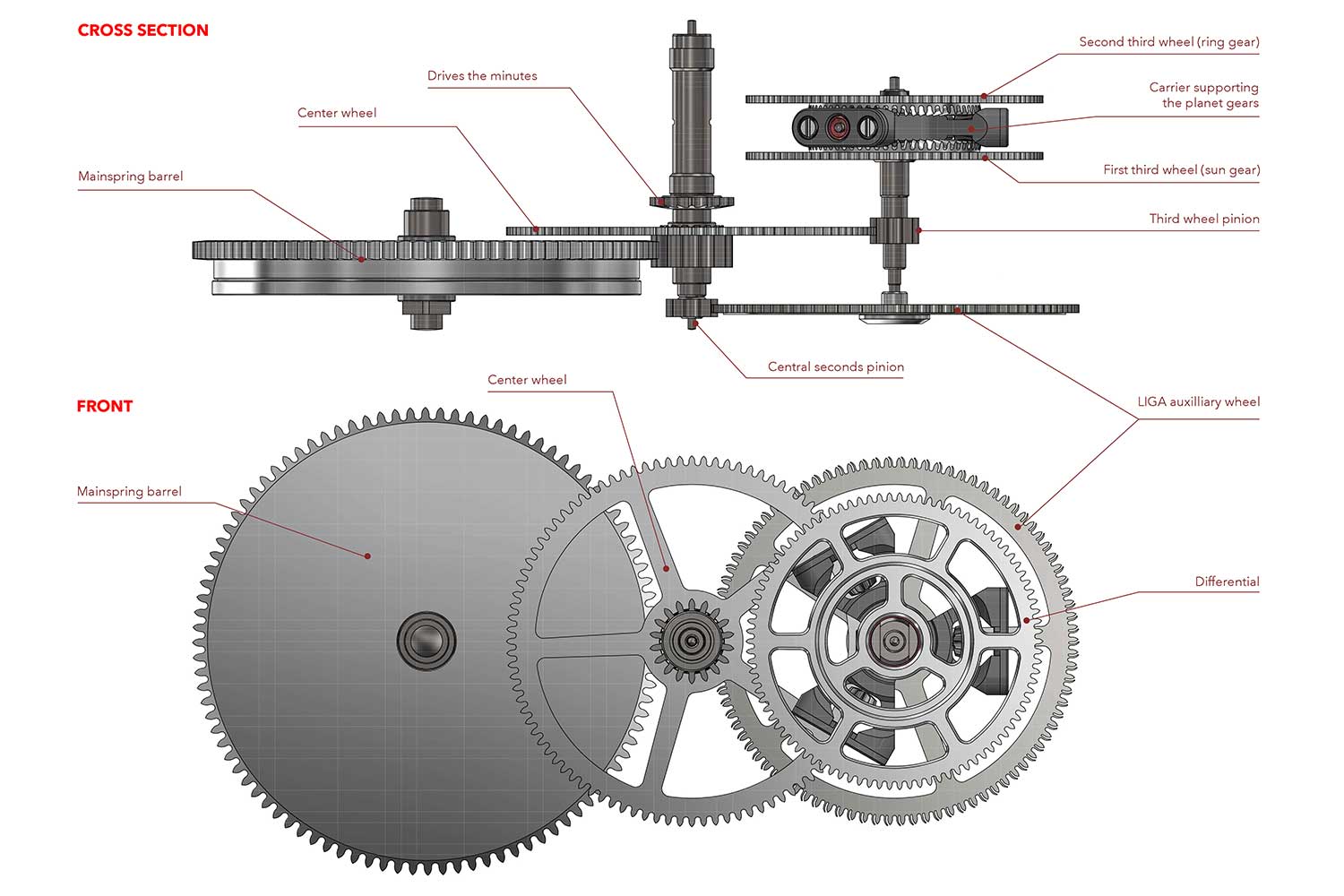

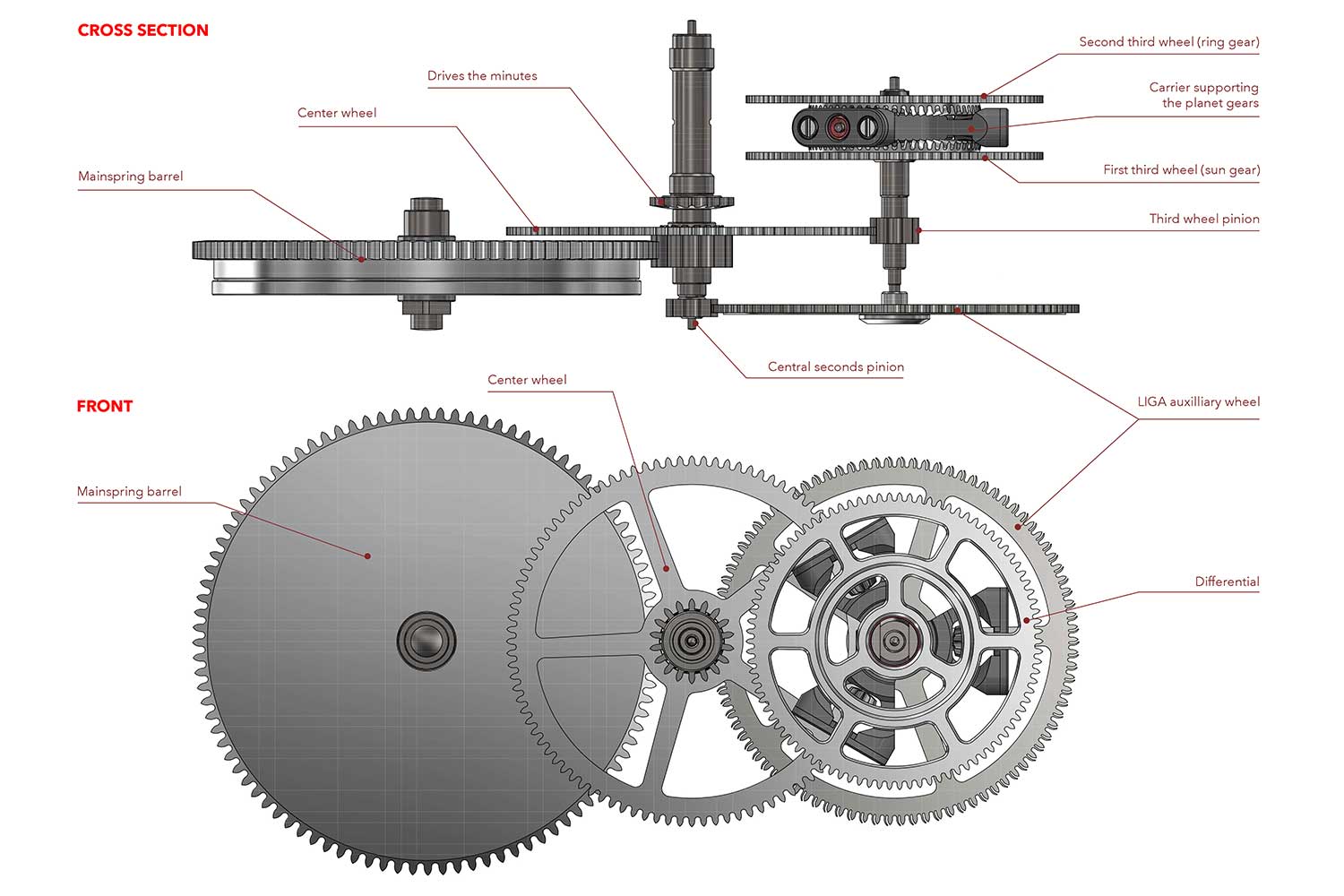

To achieve this, the movement features a convoluted but simply ingenious layout for the going train. Visible on the back of the watch are a pair of serially coupled barrels at the bottom that are wound via a crown wheel with integrated winding clicks. The mainspring barrel drives the pinion of the centre wheel, which is hidden beneath the dial. The centre wheel turns once per hour, driving the minute wheel that carries the minute pinion, which in turn drives the hour wheel, giving us the hour and minutes. Simultaneously, the centre wheel drives the pinion of the third wheel while the third wheel is positioned above the dial.

A closer look at the wheel train layout from the mainspring barrel to the differential. Central seconds is achieved with a LIGA auxiliary wheel

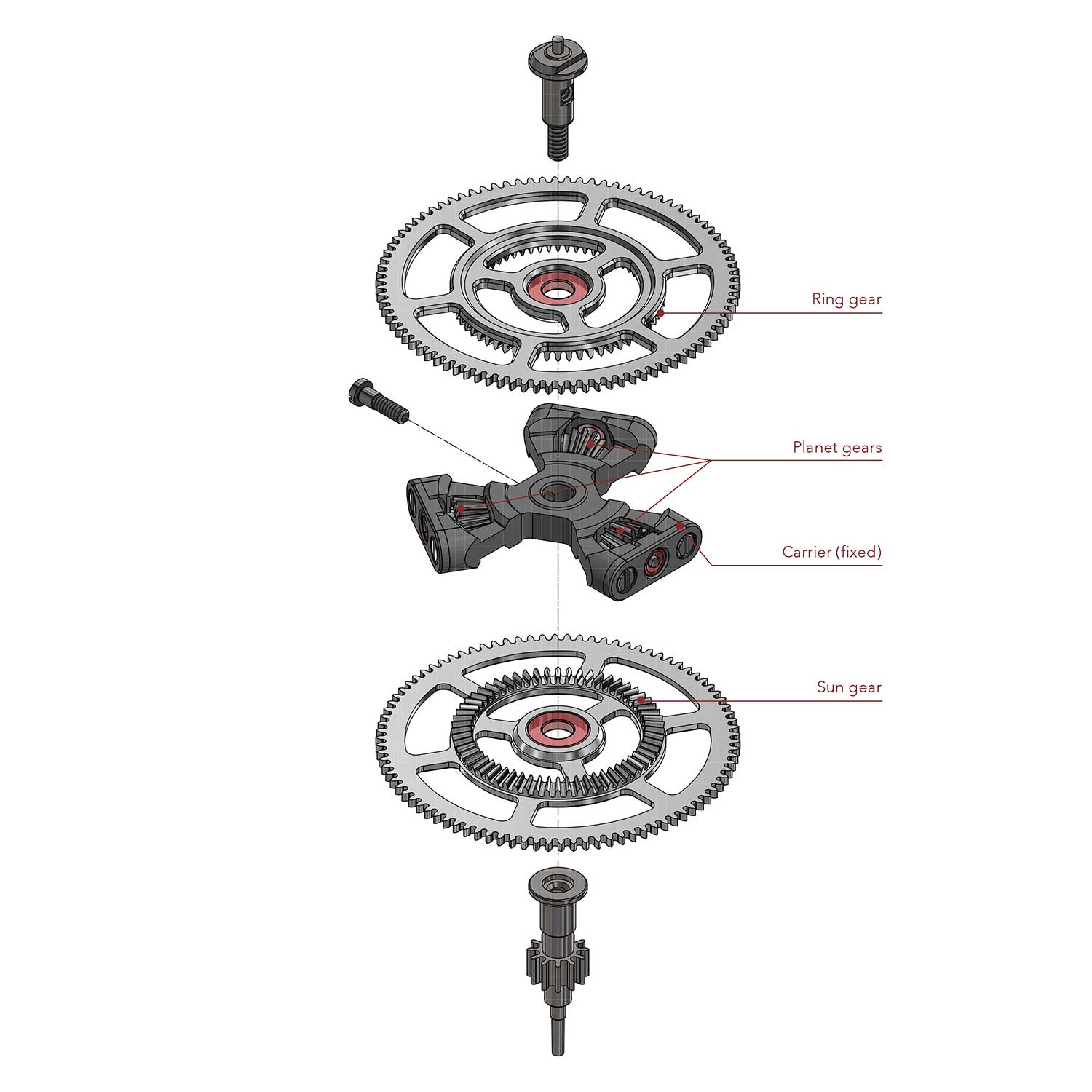

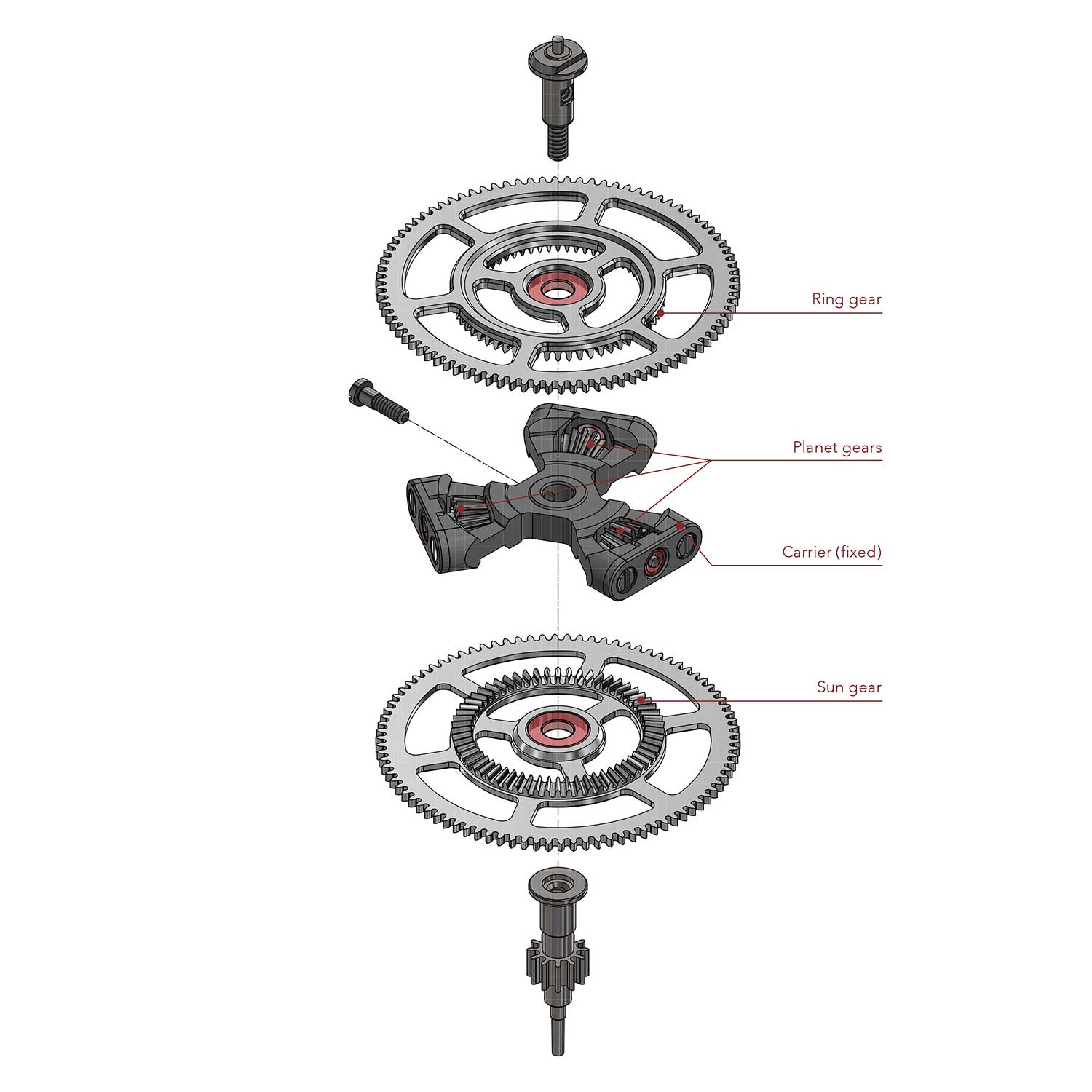

Impressively, the differential in the Place Vendôme Complicité uses planetary gears that have straight bevel teeth. Bevel gears are generally more complex to manufacture due to their intricate design requirements. It involves precise machining processes, such as cutting and shaping the teeth with high accuracy to ensure smooth engagement and minimize noise during operation.

The planetary differential comprises a sun gear (first third wheel), a ring gear (second third wheel), and three planet gears, all featuring bevel teeth. The three planet gears are held by a carrier – a chassis – made of black rhodium plated brass. The carrier is securely fastened to its shaft by a horizontal screw while the sun and ring gear are rotatably mounted with jewels installed directly in their hubs. The sun and ring gear have dual tooth profiles – flat teeth for traditional gear engagement and bevel teeth on their undersides to drive the planet gears.

The highly elaborate differential with bevel teeth. The planet gears are housed in a chassis that is fastened to the input shaft. As the sun and ring gears are identical in size and shape, power is always divided equally to both wheels

While the differential takes effect almost as soon as the watch is wound, it is still worth understanding how it does what it does in slow motion. As the mainspring unwinds, the carrier turns and the planet gears rotate on their own axis within this carrier. They will attempt to drive the sun and ring gears, which will turn slowly before picking up pace. Given that the sun and ring gears are identical in shape and size, the planet gears will distribute power equally between them.

The differential at 12 o'clock splits power to the fourth wheels, escape and balance wheels while averaging their errors in rate

Both wheels will then transmit power down their respective lines and to the balance wheels. As the balance wheel oscillates, it exerts a back-and-forth force on the escapement. The escapement, in turn, regulates the release of energy from the gear train. This interaction creates a feedback mechanism. As such, when both balances are oscillating at different rates and both third wheels are rotating at different speeds, the net effect is that the planet gears will minimize their speed difference and rotate at a speed that is a compromise between the two while maintaining a balanced power distribution.

It is worth noting that because this differential effect takes place on the third wheel, neither of the fourth wheels can directly power a small seconds function. It wouldn’t yield an intermediate or balanced output, at least from a theoretical perspective. In addition, both balance wheels in such a watch are typically adjusted to run at different rates, with the intention of achieving a balance. The goal is to find an intermediate rate that lies between the rates of each balance wheel individually, resulting in a more precise overall rate. One solution to achieve a small seconds would be to install an auxiliary train from the third wheel, but this would introduce additional inertia and play.

In the Place Vendôme Complicité, the differential is connected to a large auxiliary wheel on the same shaft. It is visible on the rear of the watch and it’s this wheel that drives the pinion for the central seconds. But look closer and you’ll notice that the individual teeth consist of cantilevered springs. This forms a reactive tooth profile that enables fuller penetration as it meshes with the central seconds pinion, eliminating backlash or play. It is produced using the LIGA (Lithographie, Galvanoformung, Abformung) process, an additive micro-electro-mechanical technique known for its exceptional precision.

A closer look at the auxiliary wheel that drives the central seconds pinion. It features a reactive tooth profile to reduce play during meshing

Offered in white gold with a grey dial or rose gold with a blue dial, the case has a diameter of 41.8mm and an overall height of 13.3mm due to its intricate gear train configuration and elaborate bevel gear differential. However, as most of the gear train is positioned on the dial, its height is merely 8.8mm, excluding the crystal. The level of finish seems to be very high, matching the ambitions of the watch. It features a full bridge that is openworked to showcase numerous sharp internal angles while the slim portion of the bridge that supports central seconds pinion is fortified by a black polished steel cap. The crown wheel with integrated clicks and click springs, a design also present in Bernhard Lederer’s Central Impulse Chronometer, subtly acknowledges the watchmaker for his contribution.

The full bridge has been openworked to showcase an abundance of internal angles

To provide a full view of its highly elaborate construction, the differential is supported by a sapphire bridge that is superimposed on another sapphire bridge that holds the fourth and escape wheels

The watch’s twin barrels provide a 72-hour power reserve which is indicated on the dial at six o’clock between the balance wheels. The balance wheels are free-sprung and operate at 3Hz. They are suspended by triangular bridges while the differential and the rest of the exposed wheels are supported by two sapphire bridges, one on top of the other, and the entire dial is protected by a box sapphire crystal. In the end, this is a watch that is as visually engaging as it intellectually exciting, a seamless blend of mechanics and aesthetics that belies an ingenuity born from narrowing the goal posts in the already exotic field of double balance and differential watches.