Dominique Renaud and Julien Tixier have formalized their partnership in a new venture – Renaud Tixier. Their first watch, the ‘Monday’, is a time-only automatic with an innovative micro-rotor system.

The last time Dominique Renaud and Julien Tixier put their heads and talents together,

a secular perpetual calendar of ingenious simplicity was birthed. Today, their partnership has evolved into an official joint venture — Renaud Tixier — with the focus of creating watches that rethink the fundamentals of a mechanical watch.

Dominique Renaud, formerly half of the renowned complications powerhouse Renaud & Papi (R&P), needs little introduction to anyone with an interest in the history of modern watchmaking. He retired from R&P in 2000 and in 2013, he co-founded Dominique Renaud SA, based in Eysins in the canton of Vaud and specialized in the field of research and technology.

The legendary Dominique Renaud and the talented 30-year-old, Julien Tixier

He collaborated with various major brands and began developing watches under his own name, beginning with the

DR01 Twelve First that incorporated a blade resonator and a shock-resistant detent escapement.

Julien, aged 30, on the other hand, is an up-and-coming talent. He developed an early passion for watchmaking, sparked by a childhood encounter with a Swiss watch.

His formal education began at the Lycée Professionnel de Bordeaux, where he obtained his first watchmaker-repairer diploma in 2011, followed by further training in the Brevet des Métiers d’Art (BMA), during which he undertook a challenging project to create a clock with a secular perpetual calendar, requiring over 3000 hours of work. Subsequently, in 2013, he pursued the Diplôme des Métiers d’Art (DMA) with a specialization in watchmaking art at the École de Morteau.

For his school piece, he created a watch with a central balance and a double retrograde seconds display.

After completing his studies, he worked on the extraordinary

‘Hippologia’ automaton for Parmigiani Fleurier and later honed his skills at movement decoration at Laurent Ferrier. After three years, he went on to develop movements for other brands, most notably a triple-axis tourbillon with minute repeater, entirely made by hand.

Later he established his own workshop in the Vallée de Joux and continued developing movements for third parties. Most notably, Julien is one of the few watchmakers capable of producing an entire watch from scratch.

Julien and Dominique at their workshop in Nyon

Their paths converged in 2016 when Julien attended Dominique Renaud’s lectures on the DR01 project, sparking a friendship that led to collaboration on the

“Tempus Fugit” project for Only Watch 2022 — an extraordinary gear-based secular perpetual calendar with a personalized countdown function based on one’s probable life expectancy.

Now with the backing of a consortium of private investors, the duo has established

Renaud Tixier and opened a workshop in Nyon, just a brief 20-minute drive from Geneva. The company is currently staffed with approximately nine members, including the founders, CEO Michel Nieto, President Jean-Luc Errant, watchmaker Sébastien Rousseau, as well as movement constructor Alexandre Bugnon and is quickly expanding.

The first watch to emerge from the new brand is the ‘Monday’, a self-winding watch with a high efficiency micro-rotor system.

A micro rotor winding system provides two main advantages over a full rotor. First, it can be integrated on the same plane as the gear train and the other components, producing a slimmer movement; second, it offers increased visibility of the movement compared to a full rotor, allowing the movement bridges to be designed with aesthetics in mind.

However, the main disadvantage of a micro winding system is that it’s inherently less efficient than a full-rotor system; they have lower rotational inertia, making it harder to fully wind the mainspring. At the same time, their lower inertia makes them more susceptible to external forces and shocks, which can disrupt their rotation.

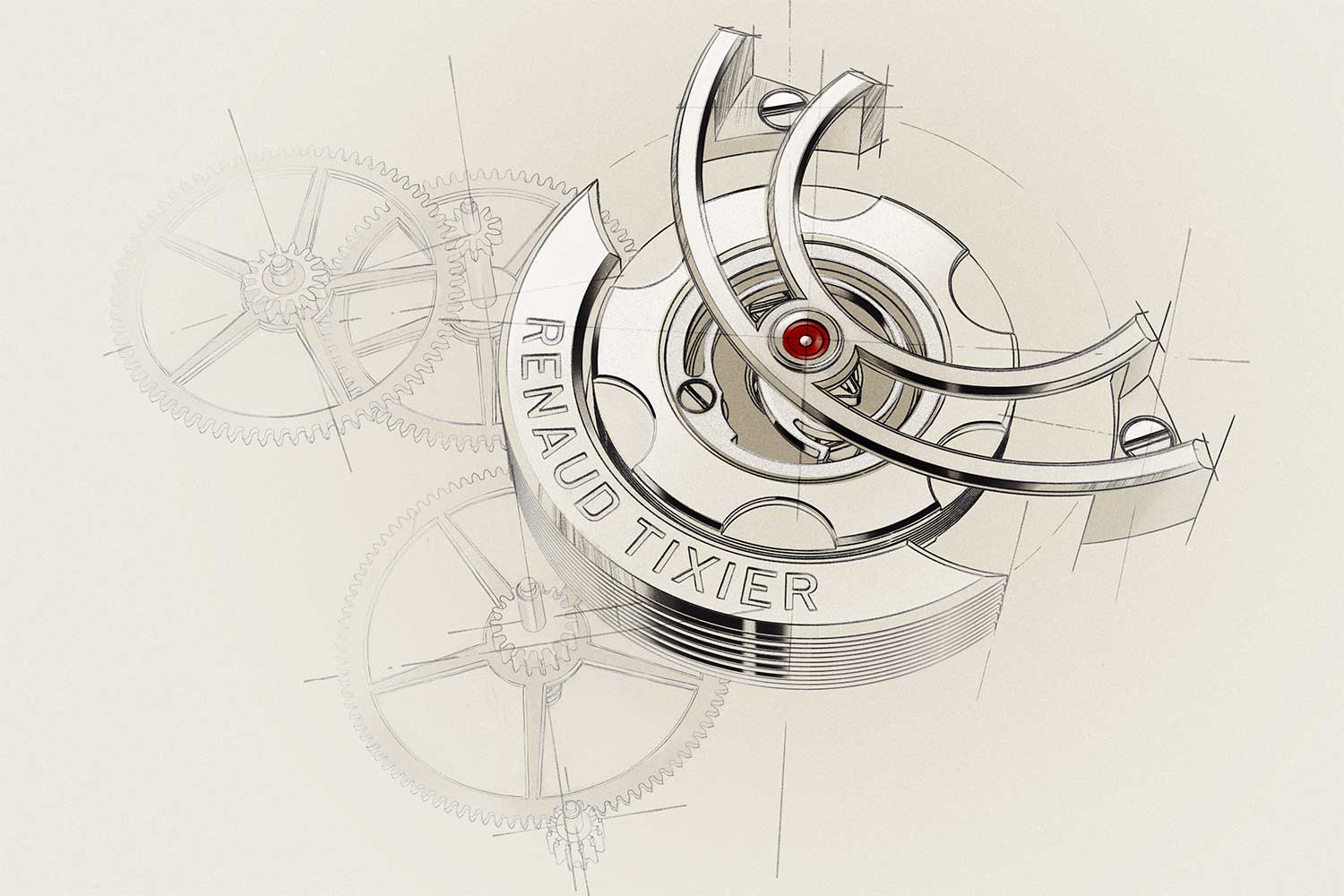

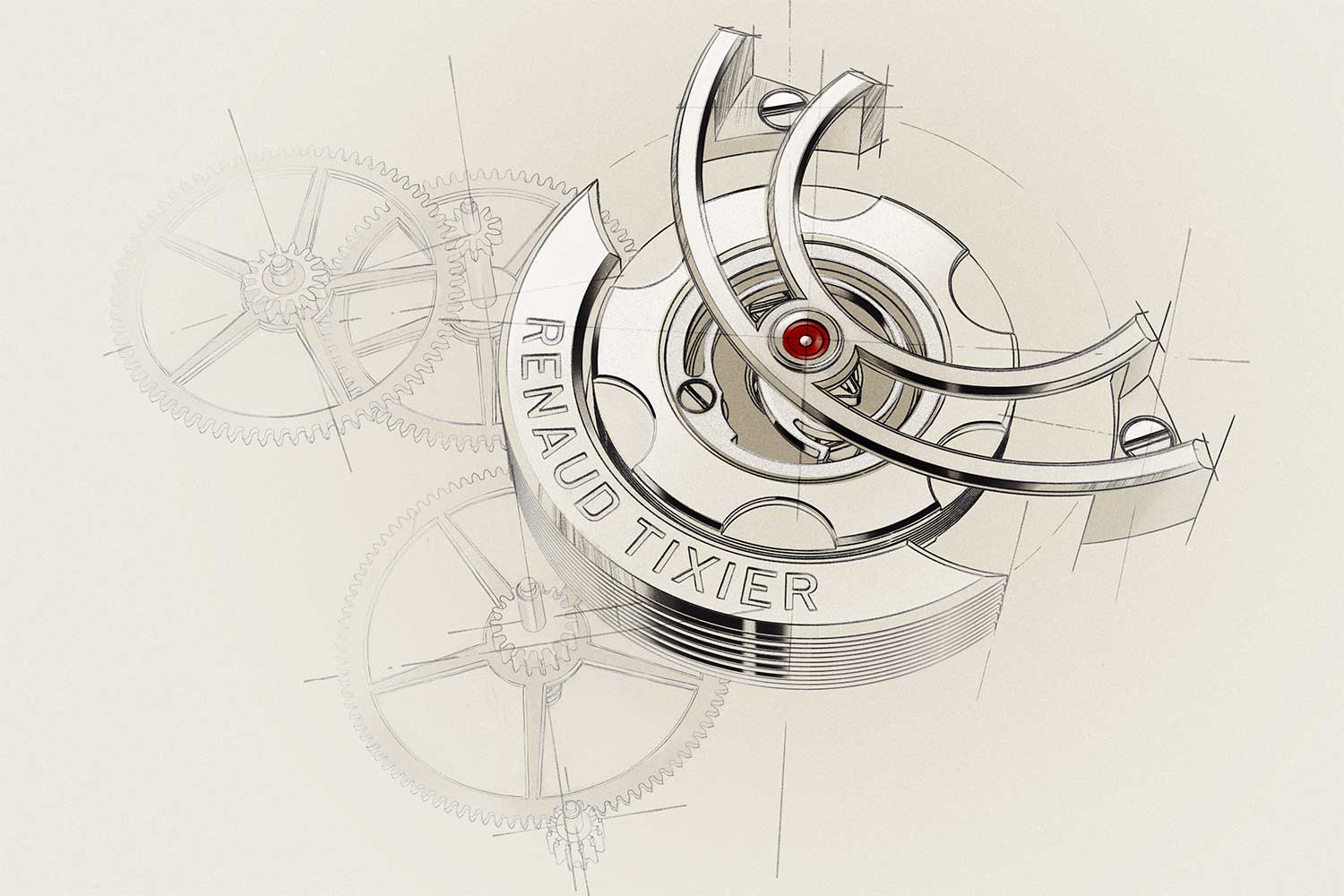

Renaud Tixier Monday Micro-Rotor

Heavy and dense metals are required to add adequate weight to the micro-rotor, such as 24k gold, platinum, or tungsten.

Given the limited evolution of micro-rotor systems, Renaud Tixier’s inaugural timepiece aims to rectify its shortcomings. Dominique Renaud observed that in a micro-rotor, “only the periphery is active, and the centre is underutilized.”

This stems from the varying moment of inertia across the rotor’s surface, where mass distributed toward the outer edges holds more influence on the winding mechanism due to its larger radius.

The micro-rotor incorporates a platinum flywheel in the middle. They are movable relative to one another; the micro-rotor winds the mainspring in both directions while the platinum flywheel winds the mainspring in one direction

Thus, at the centre of the rotor Dominique installed an auxiliary mechanism that enables the centre of the rotor to rotate independently. This mechanism consists of a platinum flywheel — an annular weight with a spring in the middle.

The micro-rotor itself is made of gold and houses the platinum flywheel within its recess. The gold micro-rotor winds the mainspring in both directions; a pair of reverser gears in brass are visible through an aperture on the dial.

The platinum weight, on the other hand, swings freely in one direction while in the other it drives the reduction gear train for the self-winding system, thus winding the mainspring. Collectively, the energy produced by both weights is adequate to ensure a large power reserve.

In the prototype, they are capable of generating a power reserve of 80 to 100 hours.

The barrel ratchet wheel has its cap decorated with engraving and filled with translucent enamel

At the centre of the platinum flywheel lies a large spiral spring that attaches the weight to the axle. The spring is designed to be resilient and precisely calibrated to suspend the platinum flywheel and enable efficient winding with the slightest wrist movement.

The inner end of the spring functions like a notched clamp. In normal circumstances, it remains rigid, effectively securing the platinum flywheel to the axle, ensuring its stability and proper function. At the same time, the spring is designed with a notch on its outer circumference and a foot.

This foot serves as a safety feature. In the event of extreme shock, the notch on the outer circumference catches the foot, causing the spring to deform.

This tension causes the notched clamp to release its grip on the axle to prevent damage. Once the shock subsides and the stored energy in the deformed spring is released, the spring returns to its original shape, and the notched clamp re-engages with the axle.

The movement itself is more dense and visually interesting compared to a traditional micro-rotor movement as the bridges have complex, unconventional shapes that exposes a great deal of the components. The reduction gears are supported by slim curved bridges and are visible on the top right quadrant of the movement.

They drive a large mainspring barrel at 10 o’clock which features a ratchet wheel with an engraved and enamelled cap. The ratchet wheel is equipped with two separate click mechanisms for controlled unidirectional winding.

Visually complex, the movement is a combination of large well-defined parts and delicate, intricate details.

The gear train is arranged on the bottom left quadrant with the center wheel located in the middle. The third and fourth wheels are supported by a slim, polished and rounded traversing bridge while the escape wheel has a skeletonized, black-polished bridge with five interior angles.

The design of the movement is interesting as it has a mix of large, well-defined parts and small intricate details. The bridge of the balance wheel, for instance, is even more elaborate.

The particularly elegant and elaborate balance bridge

One end is hollowed out and fastened to the base plate with two screws. At the opposite end, it ascends to form a circular structure with a slim black polished cap that follows its contours.

The effective length of the hairspring is adjusted with a curb-pin regulator on the slim inner arm of the balance bridge and beat error can be adjusted with the mobile stud holder. Balance power is obtained with a slow and heavy balance wheel; it beats at 18,000 vph and is made of palladium.

The visual density of the movement is further accentuated by the various kinds of surface finishing. The recesses of the base plate is decorated with perlage while the top surfaces and bridges for the micro-rotor, reduction train and balance are straight-grained with polished beveled edges and the largest bridge, which supports the centre wheel, is adorned with Geneva stripes.

In all, this is one of the most elaborately constructed and finished micro-rotor movements, putting it in the company of just a couple of independent watchmakers such as Laurent Ferrier and Romain Gauthier that have similarly pursued the art of a micro-rotor automatic to the utmost degree. But evidently what sets the Renaud Tixier Monday apart is its innovative and highly efficient micro-rotor system.

The Monday watch is available in either white or rose gold. It measures 40.8mm by 11mm.

It is slim, but not an ultra-thin watch by the numbers, with a clear focus on efficiency and elaborate aesthetics. The case has a slim bezel along with compact but elegant lugs.

The recesses along the flanks are decorated with hand-engraving and bordered by satin-brushing

It is also elaborately finished with a polished top surface, polished beveled edges, along with recessed flanks that are hand-engraved and bordered by satin-brushing.

The dial is either slate gray with a sunburst finish or silver with a grained finish. It features sword hands and applied pencil shaped hour markers with the brand’s logo serving as the 12-hour marker.

The aperture on the dial reveals the second wheel in the reverser system and the first wheel in the flywheel system

Due to the placement of the fourth wheel, the small seconds is located at an unusual position between four and five o’clock. And on the left, a cut-out at nine o’clock offers a glimpse of the gear train of the self-winding system, namely the second wheel (in brass) in the reverser system and the first wheel (rhodium-plated) in the flywheel system, itself superimposed on the first reverser wheel.

While it can’t be seen from the images, the reversers are solid wheels with internal teeth and an S-shaped pawl in their centres. The pawls act as a ratchet mechanism to ensure unidirectional rotation.

Additionally, the parts are made by Julien at his workshop in the Vallée. The watch is priced at CHF 79,000 and the company aims to produce a total of 62 pieces annually.

The dial has a dignified and somewhat austere aesthetic that provides a satisfying contrast to the visually intricate movement. The case and dial were designed by the duo and produced by external suppliers, while the movement was fully developed internally at their new workshop in Nyon.

In a time when independent watchmaking — and collecting — are characterised, in broad strokes, by ostentatious artisanal embellishments, the Monday watch represents an intriguing and refreshing proposition that brings something new to the table — in one of the most underserved areas of mechanical watchmaking — and then some.

Tech Specs: Renaud Tixier Monday

Movement: Automatic calibre RTVI2023; power reserve of 80 to 100 hours; 2.5Hz or 18,000vph

Functions: Hours, minutes, seconds

Case: 40.8mm x 11mm; 5N Rose gold or white gold; water resistant to 30 metres

Dial: Slate grey with sunburst finish or silver with grained finish

Strap: Calfskin or alligator in black, chocolate or navy blue with white or rose gold buckle

Price: 79,000 CHF (83,300 EUR/89,750 USD – based on exchange rates at time of writing, not binding, excluding VAT)