Technical

The Basics and Beyond: Perpetual Calendar

Technical

The Basics and Beyond: Perpetual Calendar

In our modern technological age, the calendar serves as a connection to the natural world, whereby the rhythms of the earth and sky coordinate with that of human life. Naturally, a mechanical watch that denotes the progress of the calendar has to embody these cosmic rhythms in gear patterns and ratios, namely the speed at which the Earth rotates on its own axis, forming the day, the Moon’s orbit around the Earth, giving us the month, and finally, the Earth’s orbit around the Sun, which marks a year.

The highest order of such watches is the perpetual calendar as it needs to accomplish a high degree of automation, namely a yearly reiteration, hence having to obey the dictates of the Gregorian calendar in which each leap year has 366 days instead of 365, giving February 29 days instead of the common 28. This means that the mechanism has to correctly care for all irregularities of the calendar, acting at the end of each month, changing itself to the first day of the following month, sometimes after 30 days and other times after 31 days, changing once a year on the 28th day of February and finally, extending February by a day every four years. The complexity of encoding this nest of rules makes the gear train of a perpetual calendar one of the most intricate, perhaps second only to that of a minute repeater — both of which, with much irony, are driven by the humble motion works that spell out the time in every watch.

The instantaneous date mechanism in the H. Moser & Cie. Perpetual Calendar

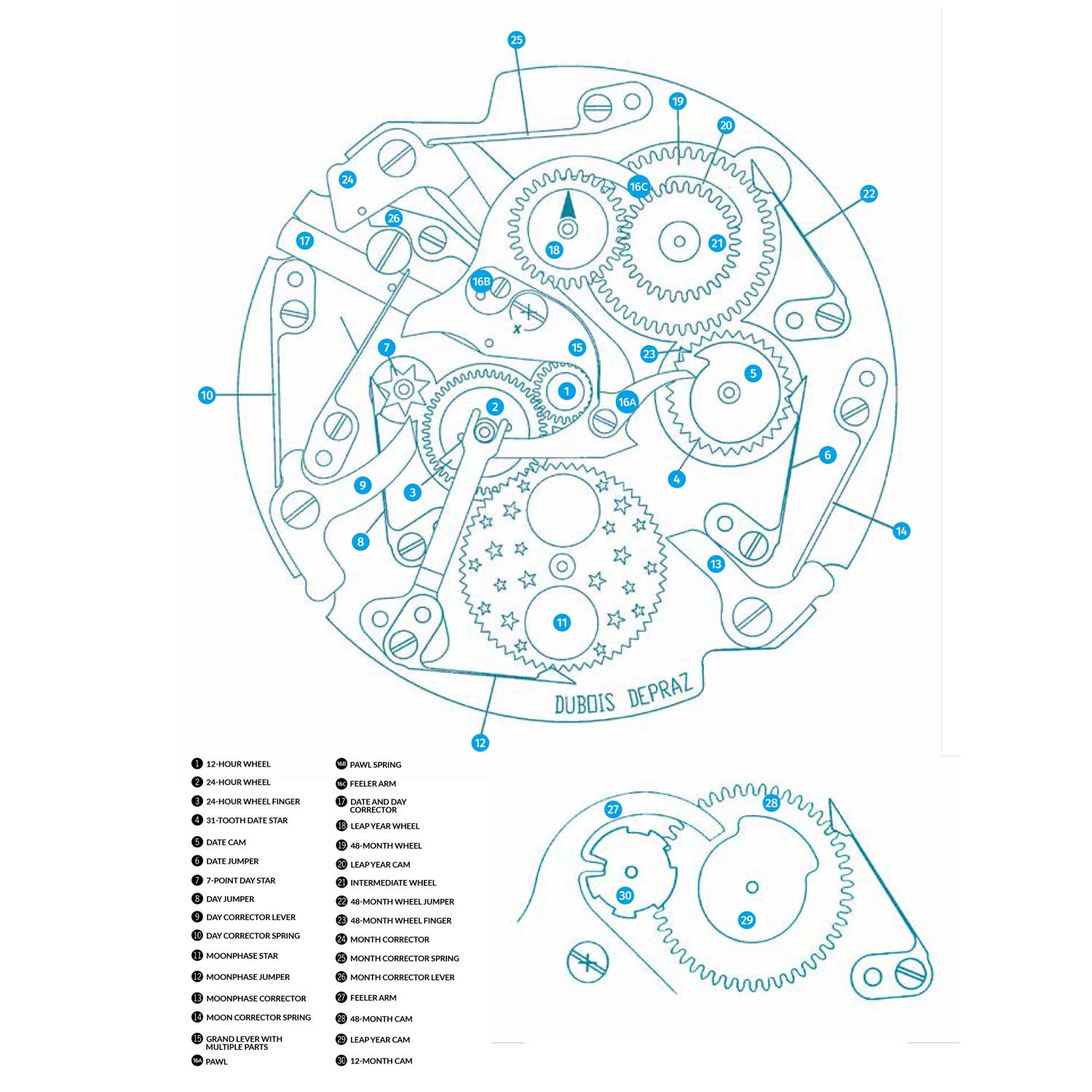

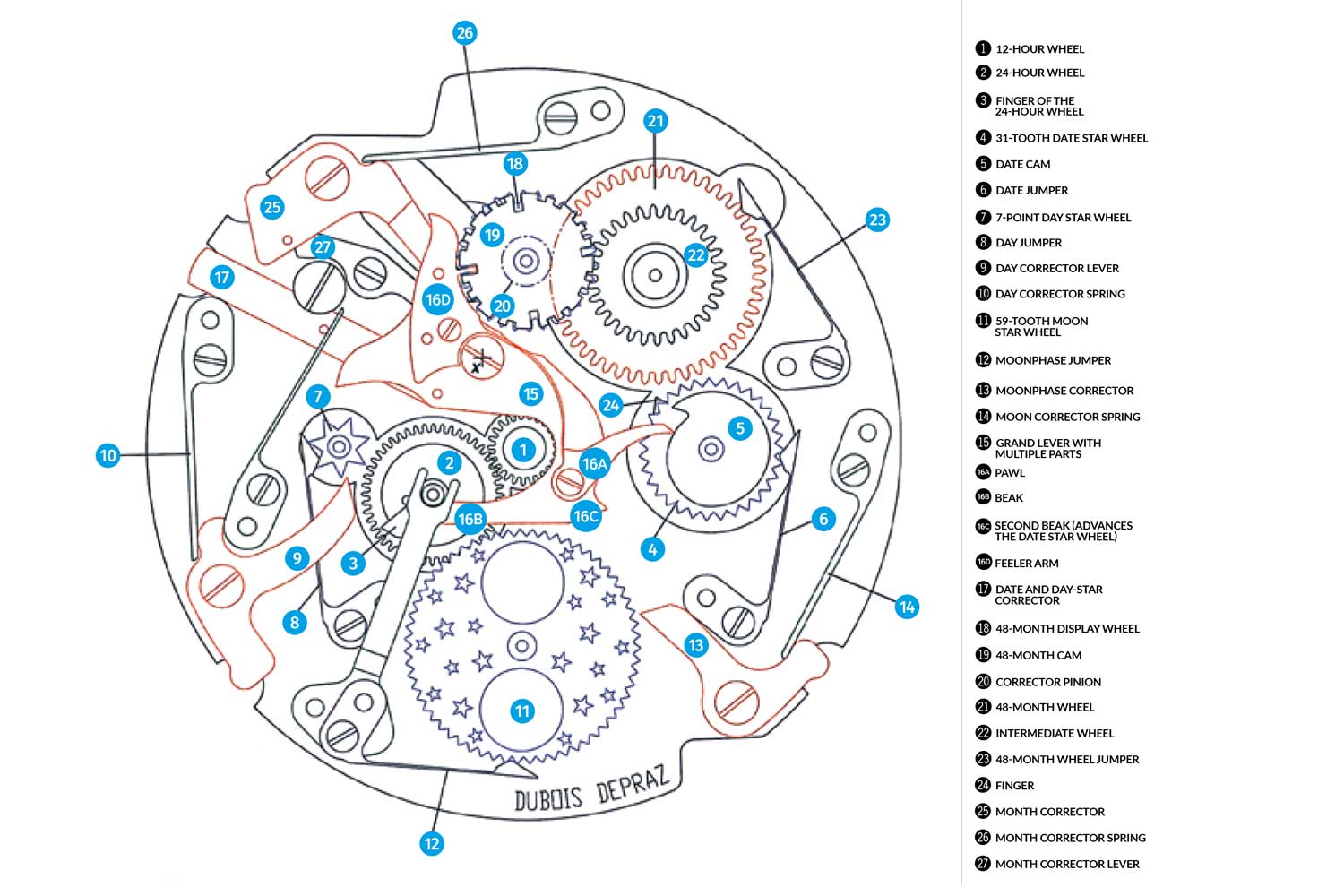

Perpetual calendars are predominantly executed in one of three formats. It can be designed with a 48-month cam that encodes the length of the months in a four-year cycle with notches of varying depths, a 12-month cam which functions the same way but makes a revolution once a year while working with a separate leap year cam, or a 12-month cam with an integrated Maltese cross satellite to manage the month of February. At the heart of each format is a grand lever that advances the date one day forward every day at midnight and is built to automatically advance past the additional days at the end of months shorter than 31 days.

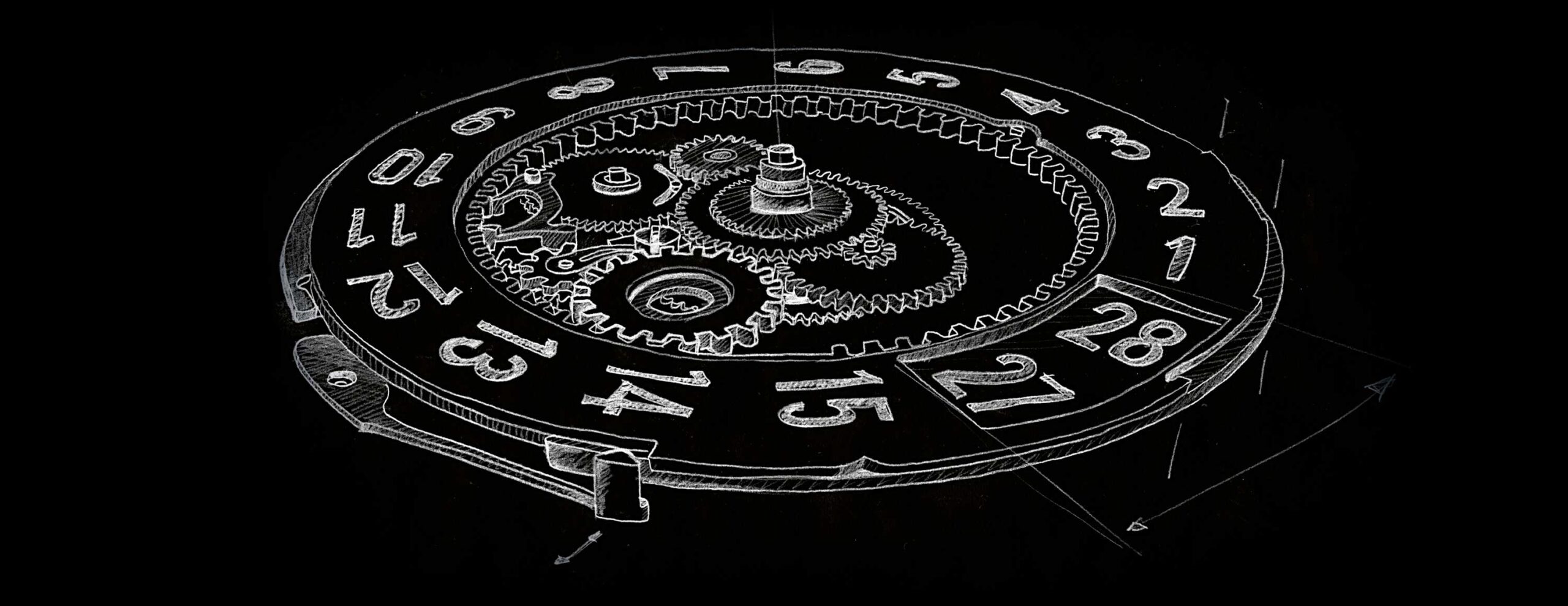

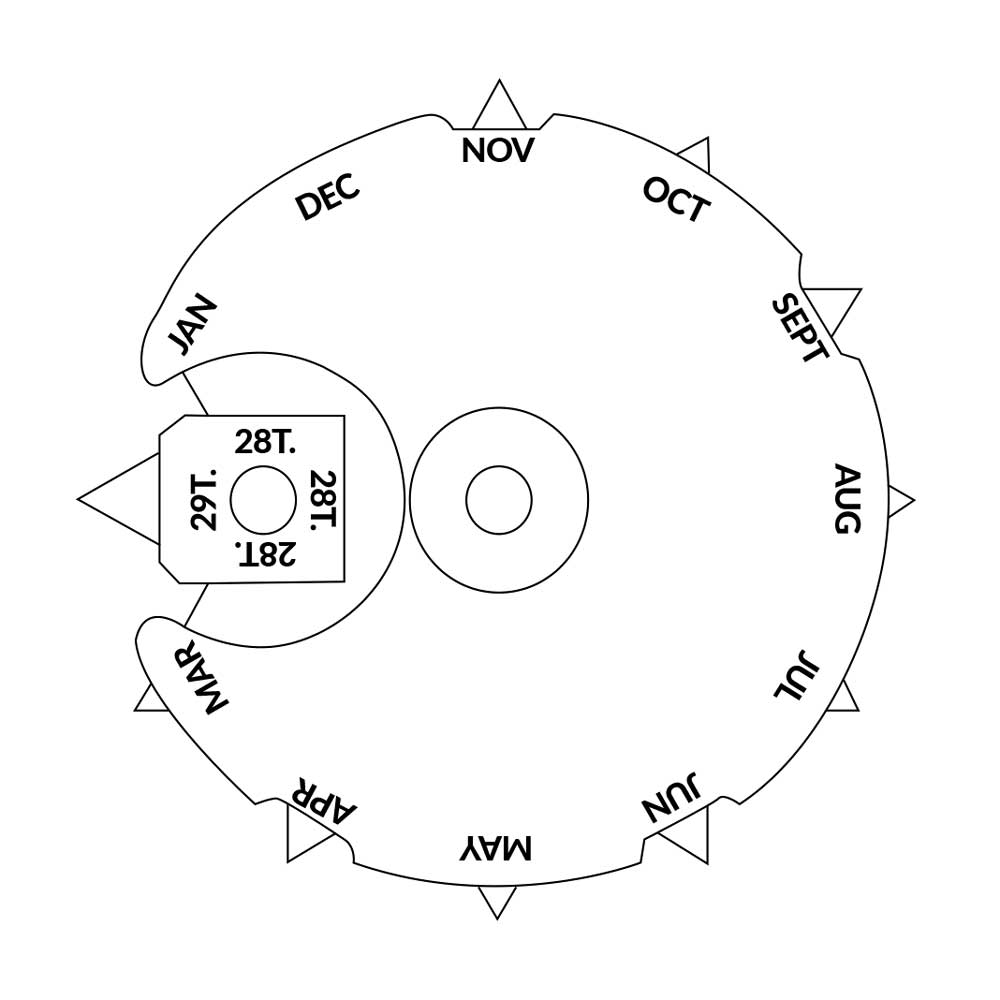

From top: An example of a perpetual calendar with 12-month cam; The 12-month cam (30) works in conjunction with a leap year cam (29)

48-MONTH CAM

The gear train that encodes the units of the date — day, month and year — are derived from the motion works, specifically the hour wheel of a watch. This makes the gear train of a perpetual calendar mechanism, like the motion works itself, a reduction train. As illustrated in the diagram, driven by the motion works below the calendar plate is a 12-hour wheel that drives a 24-hour wheel. Affixed to it is a finger that indexes a moon gear, typically with 59 teeth to account for two lunar cycles, advancing it by one notch every 24 hours. At the same time, this finger also comes into contact with the arm of a grand lever, lifting it every 24 hours. The grand lever then pivots, and another arm engages a seven-point day star wheel, moving it forward by one step. At this point, a beak on the grand lever also comes into position to actuate a 31-tooth date star wheel, advancing it by a notch.

The grand lever, thus, pivots varying amounts based on the month — further for short months and lesser for long months. At the end of the month, the fourth arm on the grand lever locks into a date snail cam and forces the date change. Hence, if the grand lever pivots further, it catches the snail cam at an earlier date.

The date star carries a finger that engages a 48-month wheel at the end of every month. An intermediate wheel affixed to it then drives a 48-tooth wheel, consequently rotating the 48-month cam.

It is difficult to determine which format of program wheel is used by looking at the dial as there are ways to achieve a desired design regardless of which is used; watches that adopt a 48-month cam do not necessarily have a 48-month indicator. Known examples that use a 48-month cam system are any of Patek Philippe’s three- register perpetual calendars.

12-MONTH CAM WITH SEPARATE LEAP YEAR CAM

A 12-month cam differs primarily from a 48-month cam in having a rotation speed of one turn per year. As such, a leap year, which occurs once every four years, cannot be encoded in this cam. It consists of notches of only three varying depths, accounting for 31, 30 and 28 days. To account for February 29, the 12-month cam works in conjunction with a separate leap year cam.

Patek Philippe Perpetual Calendar 5327G (left) and Perpetual Calendar Chronograph 5270J (right). As a rule of thumb, all Patek Philippe’s perpetual calendars with triple counters employ a 48-month cam while other configurations rely on a 12-month cam (Image: ©Revolution)

This limits the travel of the grand lever which then catches the date cam later and advances three steps at the end of the month.

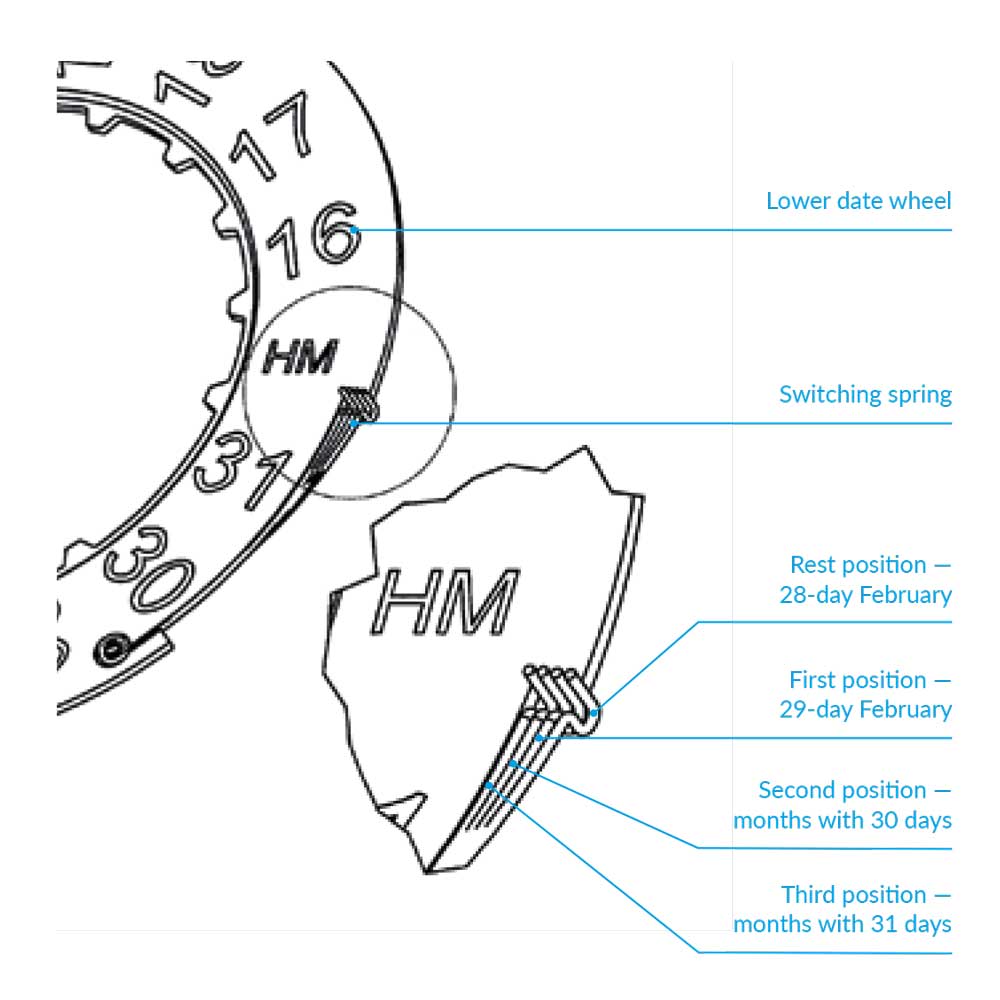

12-MONTH CAM WITH MALTESE CROSS SATELLITE

An alternative to having a separate leap year cam is to incorporate a Maltese cross system in the 12-month cam to manage the month of February. In this format, the 12-month cam is affixed to the month star wheel and consists of two depth profiles, with the full diameter corresponding to months with 31 days, and shallow recesses that take care of months with 30 days. The cam features a cutout where February ought to be and in its place is a leap year cam. The latter has four points — three identical points of the same height and one point that is longer. This cam is fixed to a Maltese cross that is pivoted on the month star.

The 12-month cam with a satellite wheel to manage the month of February

ADJUSTMENT VIA CORRECTORS

While a perpetual calendar only requires a correction after every full century when the Gregorian calendar omits a leap year, like a regular watch, it comes to a halt when the mainspring winds down. Thus, correctors are installed so that the day, date, month and moonphase can be manually adjusted with little pushers set into the caseband using a stylus.

Each indicator has its own corrector in the form of a lever that overcomes the tension of a spring when it is depressed, enabling adjustments to be made forward. When changing the month, a lever lifts the grand lever, so the 48-month cam is freed and the corrector lever advances a pinion, which drives the 48-month wheel. The day star can be set independently with its own pusher and corrector lever as well as together with the date via a second pusher that acts on the grand lever.

BREAKING THE MOLD: IWC DA VINCI PERPETUAL CALENDAR

The complex, notably three-dimensional construction of a perpetual calendar characterized by levers and springs results in high cost in manufacturing and assembly. Hence, for a long time, perpetual calendars remained the preserve of top watchmaking companies the likes of the holy trinity.

But in 1985, a new wind began to blow when IWC introduced the Da Vinci, the first perpetual calendar in which all indications can be adjusted via the crown. Designed by the firm’s legendary head watchmaker Kurt Klaus, the calendar mechanism did away with corrector levers and reduced the number of intermediate components by having each display wheel drive the next directly, greatly reducing part count. As such, the movement was notably compact and slim while the calendar display was remarkably complete with the addition of a full four-digit year.

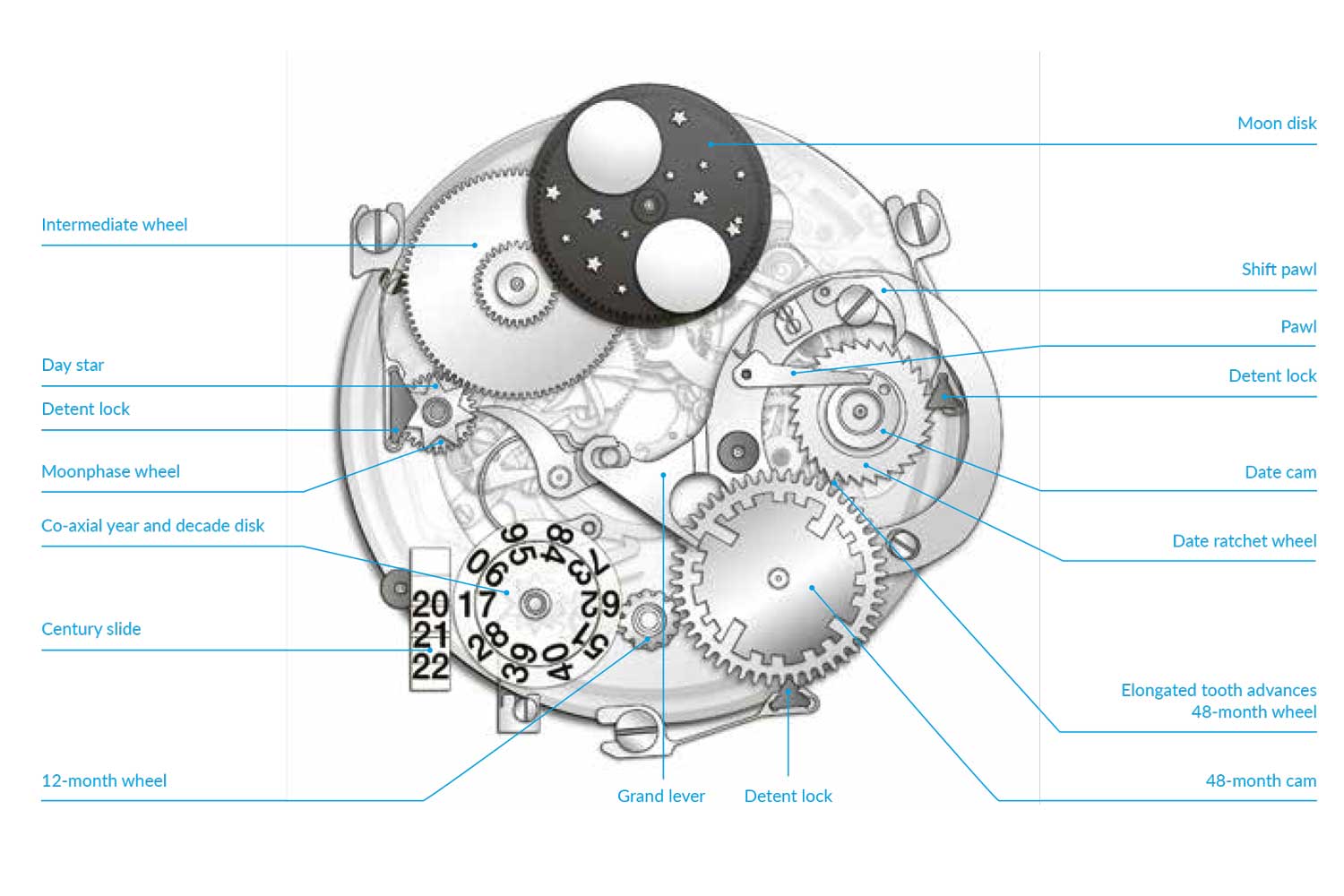

The ingenious perpetual calendar module developed by the legendary Kurt Klaus

IWC Big Pilot’s Watch Perpetual Calendar Edition “Rodeo Drive”

In effect, the date wheel indexes the 48-month wheel directly and the latter drives a 12-month wheel on which the month hand is mounted. The 12-month wheel has a finger affixed to it that engages a pair of co-axially mounted intermediate wheels of the same diameter and pitch. The first wheel has 10 teeth while the second has a single tooth. They mesh with another pair of identical co-axially mounted wheels to achieve a digital year display. One gears with the 10-tooth wheel, giving us the year and the other, the single-tooth wheel, forming the decade wheel. Thus, the year wheel is moved once a year by one tooth and the decade wheel is advanced once every 10 years by one tooth.

IWC Portugieser Perpetual Calendar 42

The daily swinging motion of the grand lever also advances a day star by one tooth. The day star, pivotably mounted on a moonphase wheel, drives a reduction train at a ratio of 8.4375:1, enabling the moon disk to make one rotation every 59.0625 days.

REINVENTING THE WHEEL: ULYSSE NARDIN PERPETUAL LUDWIG

Following IWC’s breakthrough, developments that followed the same path of simplicity slowly began to emerge. The most significant was the Ulysse Nardin Perpetual Ludwig launched in 1996 to mark the brand’s 150th anniversary.

The watch was named after Ludwig Oechslin, a Vatican clock restorer and polymath, who spearheaded the rebirth of Ulysse Nardin, along with its visionary owner, Rolf Schnyder. The Perpetual Ludwig was the first perpetual calendar that enabled forward and backward date adjustments over a single crown.

The landmark Ulysse Nardin Perpetual Ludwig can be adjusted both forwards and backwards via a single crown

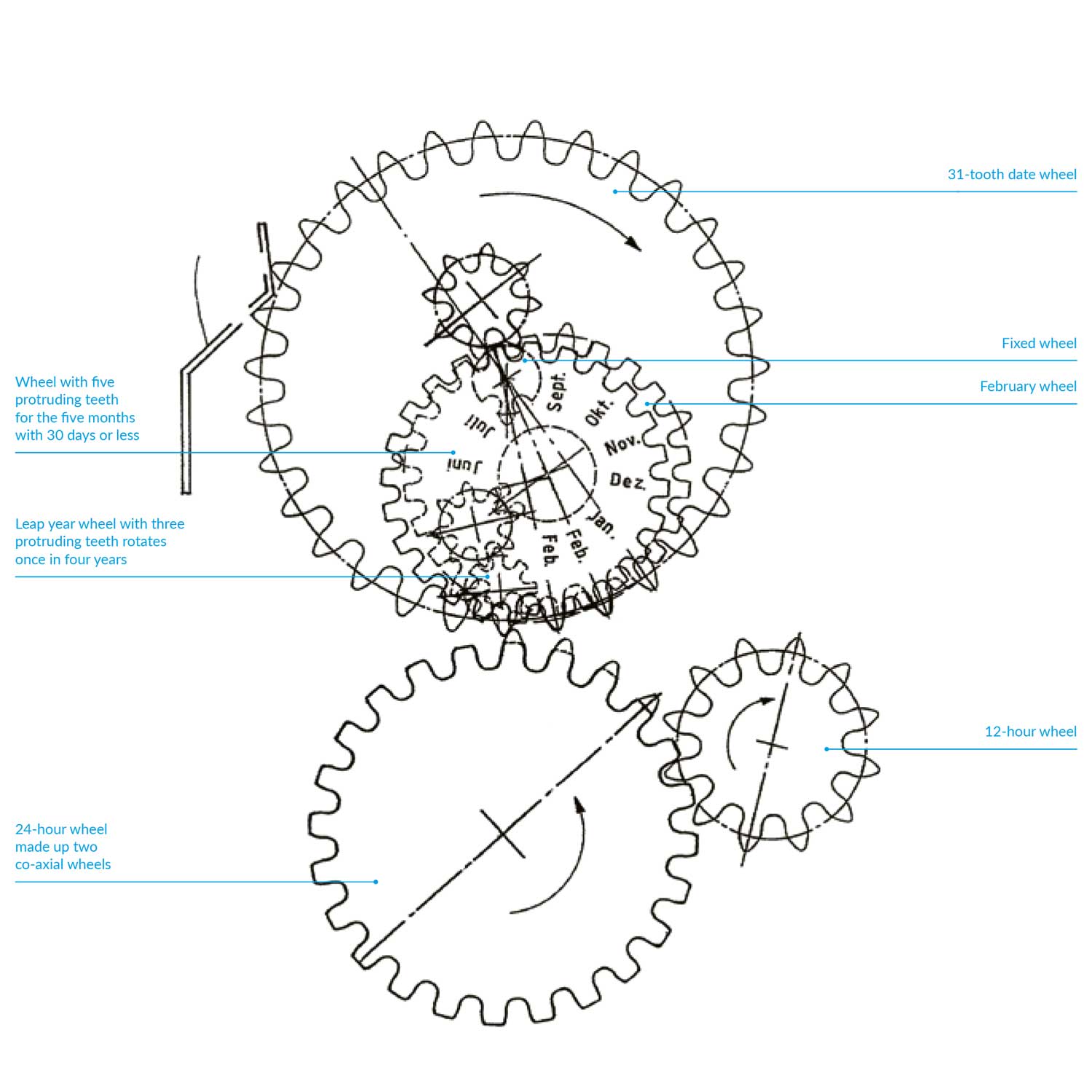

At the heart of the mechanism is a pair of co-axial wheels — a 31-tooth date wheel that completes one revolution per month and a co-axial fixed wheel. The date wheel is driven forward by a 24-hour wheel, which, as with a standard perpetual calendar, is controlled by the hour wheel. However, this 24-hour wheel comprises of two stacked wheels — the first wheel with a single long tooth to advance the date wheel by one tooth at the end of months with 31 days and the second wheel, superimposed on the first, with three successive long teeth to take care of months with 30, 29 or 28 days. The wheels are offset such that the long tooth of the first wheel is immediately followed by the three long teeth of the second wheel to advance the date wheel by additional steps at the end of months with less than 31 days.

Ludwig Oechslin’s perpetual calendar mechanism from the original patent

The date wheel itself is mounted on a large finger cam, which indexes a pinion at the end of the month. This pinion in turn drives the month wheel.

As a result of being entirely made of gears, the calendar can be adjusted both forward and backward and is eminently more resistant to shocks, making it more robust.

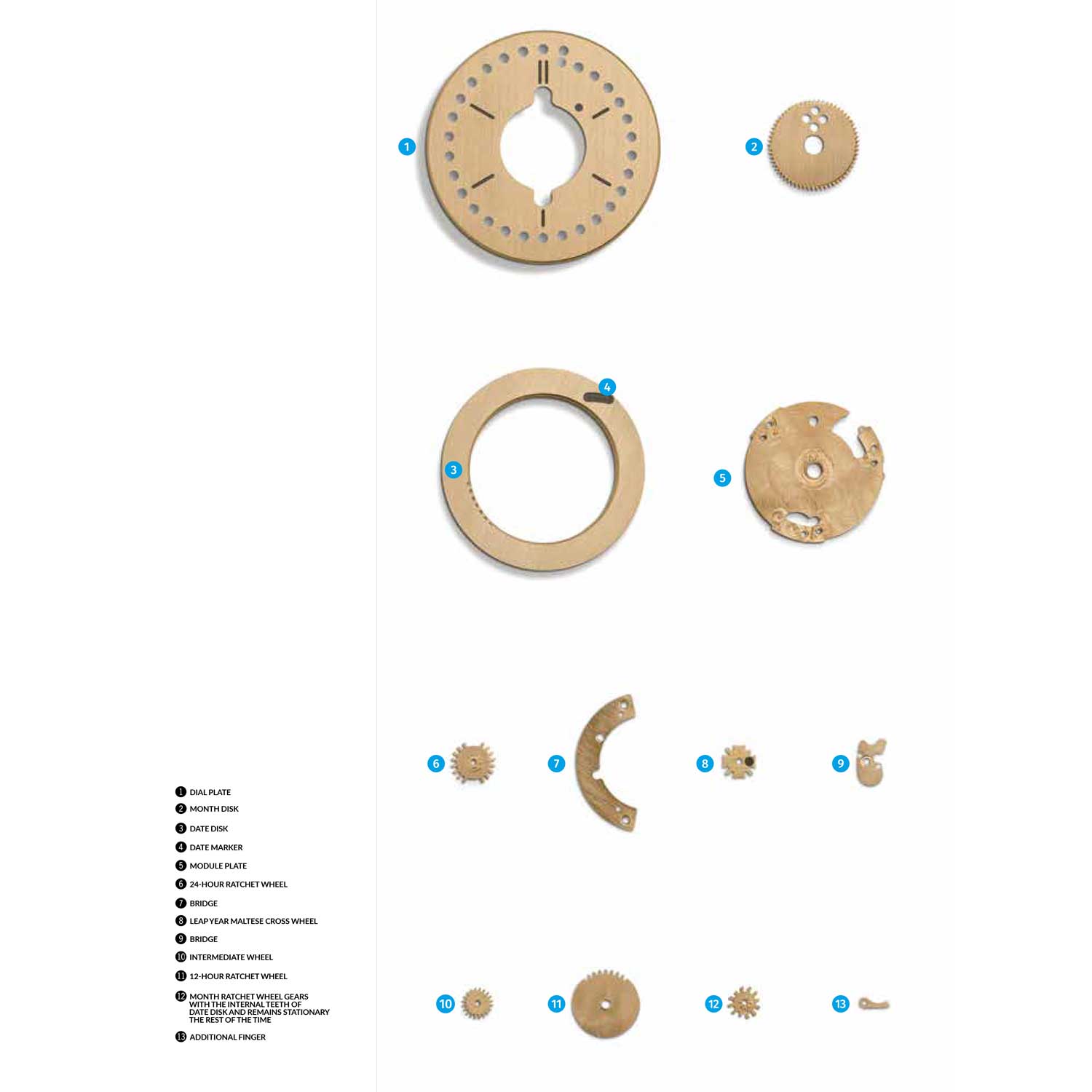

THE MOST ADVANCED PERPETUAL: H. MOSER & CIE. PERPETUAL CALENDAR

In 2005, H. Moser & Cie. went a step further and developed an instantaneous perpetual calendar that enabled forward and backward adjustments of the date via a single crown. Aside from being predominantly made of gears, Moser’s perpetual calendar introduced two more factors to the equation that made its construction inherently unusual — a centrally-mounted month hand and an instantaneous date wheel — hence, differing drastically from Ludwig’s invention. While the resulting mechanism is exceedingly simple and practical, it required nothing less than the genius of Andreas Strehler, an independent watchmaker who is best known for having developed the most precise moonphase indicator in the world with an error of only one day in 2,060,757 years.

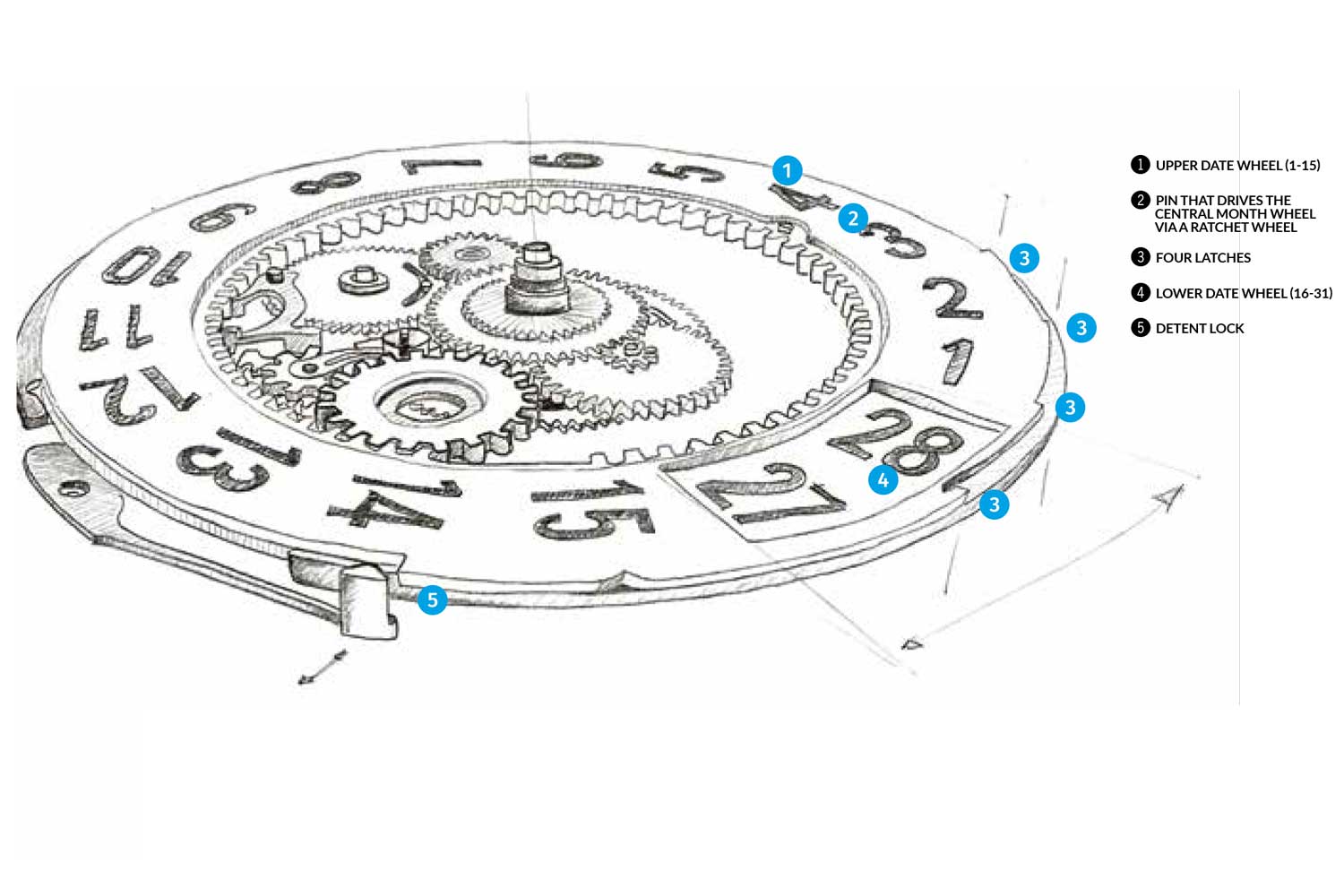

The date mechanism consists of two disks, arranged one over the other and operates in a relay. The top date disk bears the date numerals “1” to “15” followed by an aperture, through which the bottom disk with “16” to “31” can be read. In the second half of the month, the top disk is stationary with the aperture positioned at three o’clock and the bottom disk advances. At the end of the month, the top disk makes a single jump to the first day of the following month.

The “Flash Calendar” instantaneous date-change mechanism

A closer look at the unusual switching system on the bottom disk that acts on a series of four latches on the circumference of the top disk

H. Moser & Cie. Endeavour Perpetual Calendar Tutorial; Endeavour Perpetual Calendar Funky Blue

In addition, a pin on the top date disk indexes a ratchet wheel — their engagement akin to a Maltese cross system — which drives the central month wheel via an intermediate gear.

EXTREME REDUCTION: OCHS UND JUNIOR PERPETUAL CALENDAR

When Ludwig Oechslin founded Ochs und Junior in 2006, he began streamlining the complication even further by rethinking its basic design and in 2016, arrived at a perpetual calendar module that was made up of just nine components. The novelty lies not only in the way the calendar mechanism was constructed, but also the way the indications were displayed, which made the severe reduction possible.

The date is displayed using an outer ring of 31 perforations with an elongated colored date marker printed on a rotating disk beneath it. Thus, the marker appears through the perforation to indicate the date, which can be conveniently read against the 10-minute markers, each representing five days. The month, on the other hand, is indicated by a set of four perforations on a centrally mounted disk that makes a complete rotation in 12 months, while leap year is indicated by a colored dot that emerges on the outward facing perforation in February of a leap year. In other words, in February of three common years, the colored marker is on one of the three inward perforations.

Assembly of Ludwig Oechslin’s 12-part perpetual calendar mechanism

These examples are particularly enlightening in demonstrating that the ease of use and simplicity in design, construction and assembly of a modern perpetual calendar belie some seriously creative and complex solutions. As such, despite their obvious utility and necessity, these advancements remain a rarity in watchmaking.