Feature

Hublot and the ‘Art of Fusion’

Watchmaker placing the dial of Classic Fusion Chronograph on the movement before casing up

Hublot Research and Development

Hublot prizes the innovations that create new possibilities, and strives to maintain their place in the forefront of the innovators. One look at the R&D lab at Hublot manufacture and it’s clear that the brand prioritizes this aspect of their business. They have nicknamed their team the “F1 of watchmaking” and it is comprised of 30 people with talents in watchmaking, design, engineering, micro-dynamics and micro- chemistry, who are dedicated to advancing Hublot’s arsenal of materials and architecture.

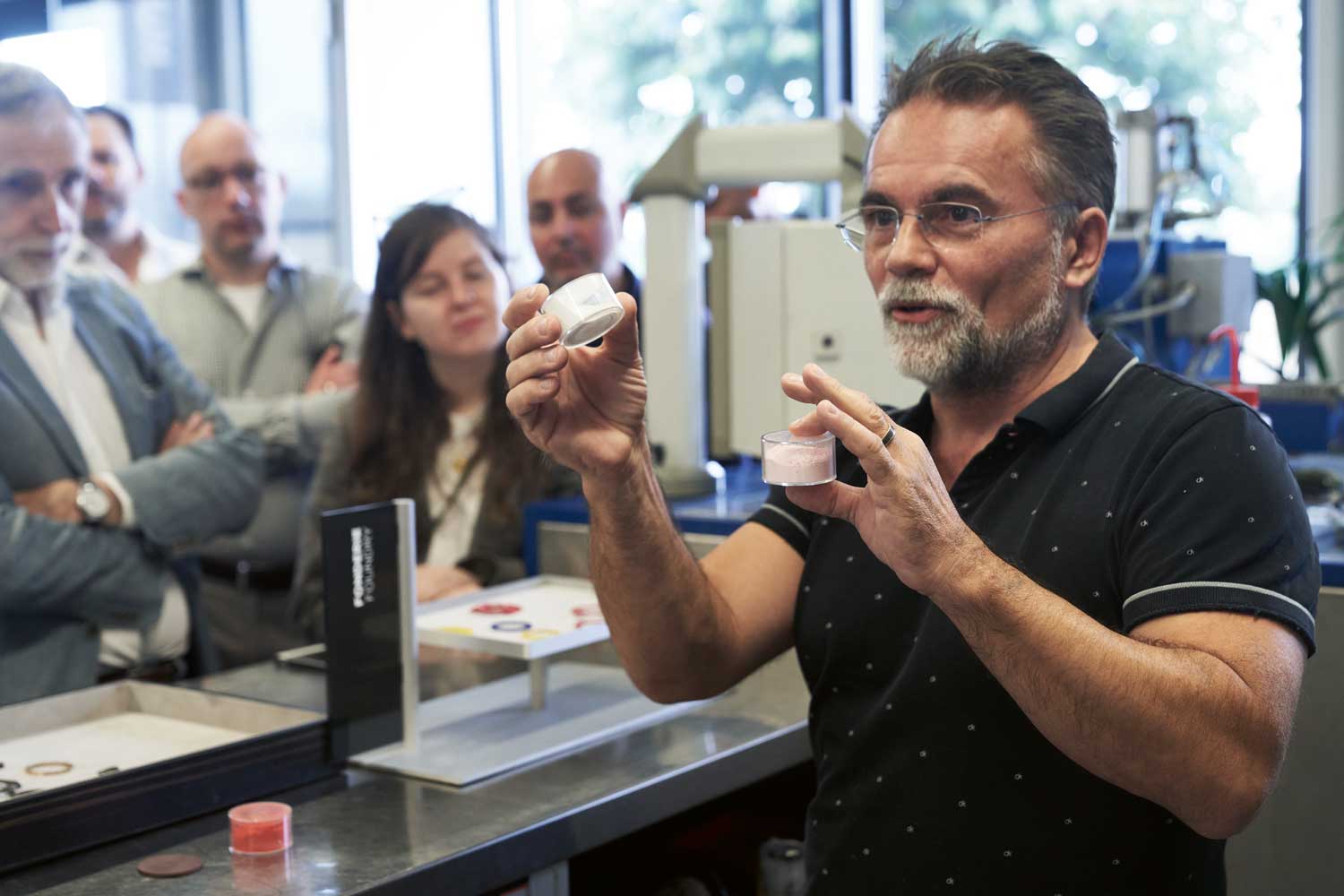

Matthias Buttet, R&D director, explaining the fascinating process of producing vivid color ceramic

Material Mastery

In 2011, Hublot partnered with the Swiss Federal Institute of Technology in Lausanne (EPFL) to create an 18K gold alloy that combines gold and porous ceramic named “Magic Gold.” This alloy gives the look and feel of gold, but has the scratch-proof properties of ceramic. “With Magic Gold, it was like Hublot acquired a black belt in a martial art, and with this, we got the first dan,” Buttet said.

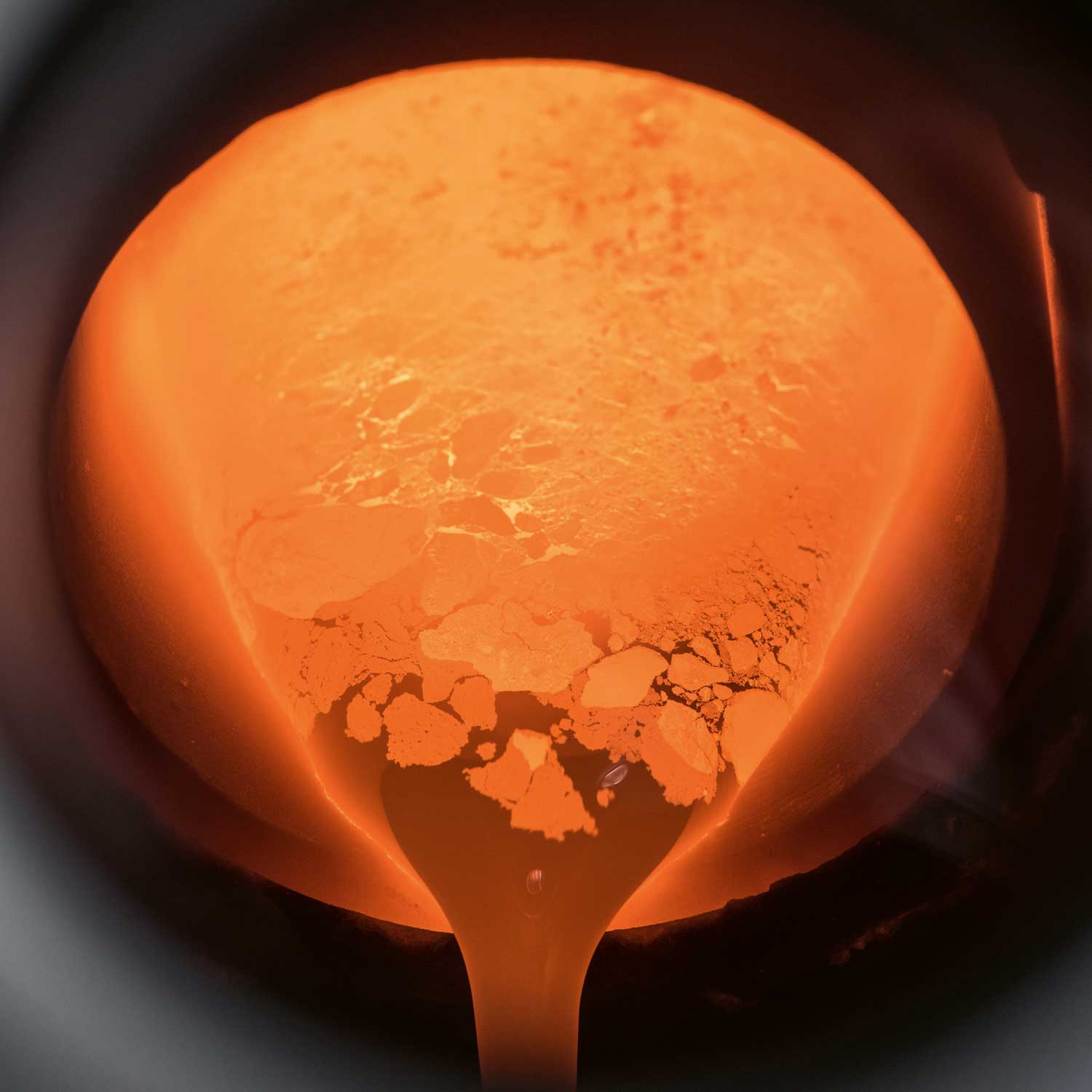

The art of fusion with Magic Gold

Ceramic and gold for the Magic Gold

Magic Gold preparation in the foundry

Another great advancement is the brilliant cherry red ceramic that Hublot calls “Red Magic” — a red ceramic material achieved by fusing iron oxide and ceramic under intense heat and pressure with a precision that proves their mastery of material engineering. Because of this work, Hublot has gone on to be the first brand to offer watches in colored ceramics like white, black, red, blue and green.

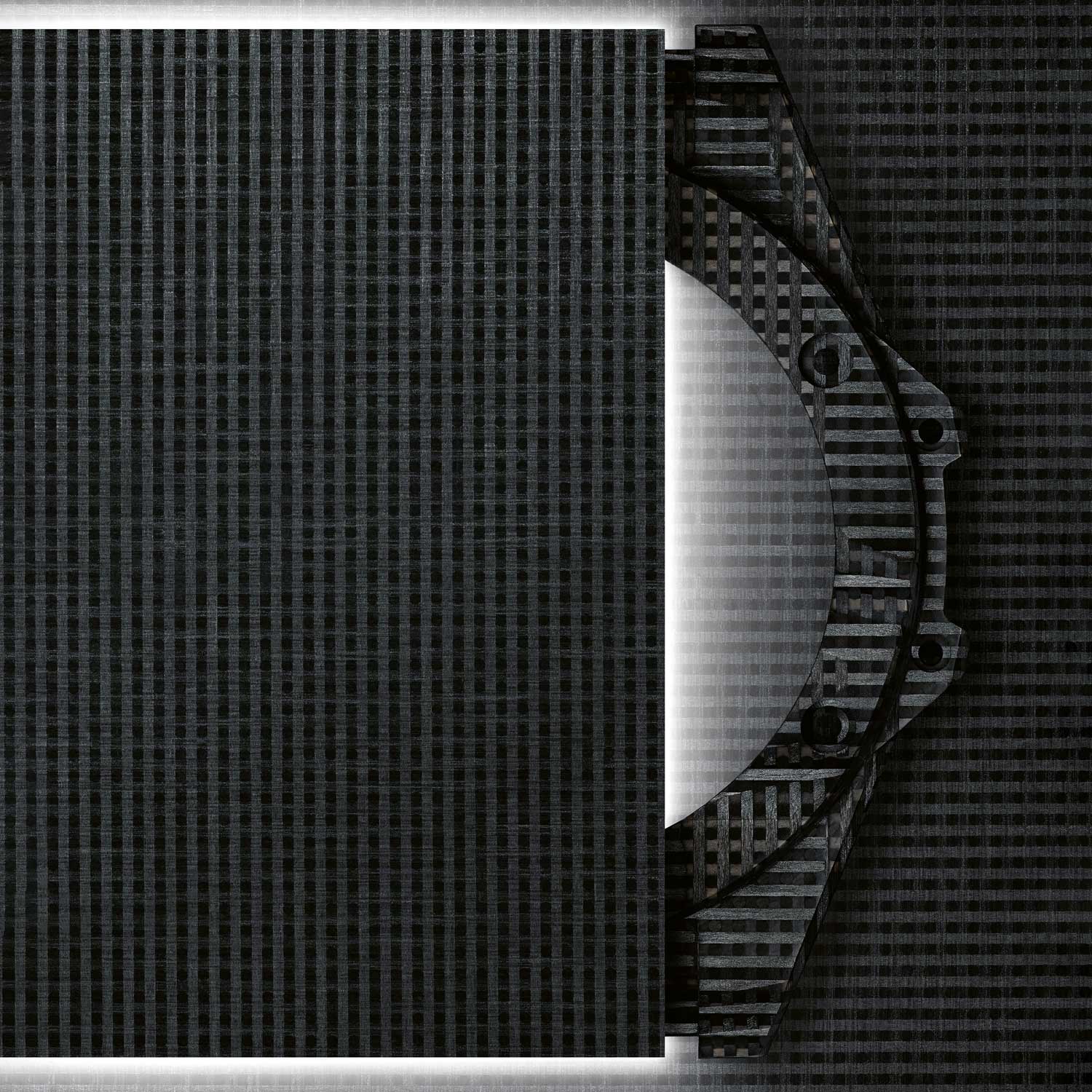

Other metal alloys have come from their laboratory workshop, including a gold and platinum combination named King Gold, a magnesium and aluminum alloy cheekily named Hublonium, and the carbon fiber and aluminum mix named Texalium.

3D carbon fiber case used in MP collection

Blue sapphire case

Expert Technique

The work done by the R&D team extends beyond the material sciences. The designers and engineers have experimented with mastering new ways of working with those materials, most notably their mastery over the realm of setting precious stones. Their “invisible setting” method was developed to cut and polish a gem with such precision that it can be set in its place with no visible prongs. They were also able to develop ways to encrust gems and stones into their transparent sapphire cases, despite the incredible difficulty in cutting the material.

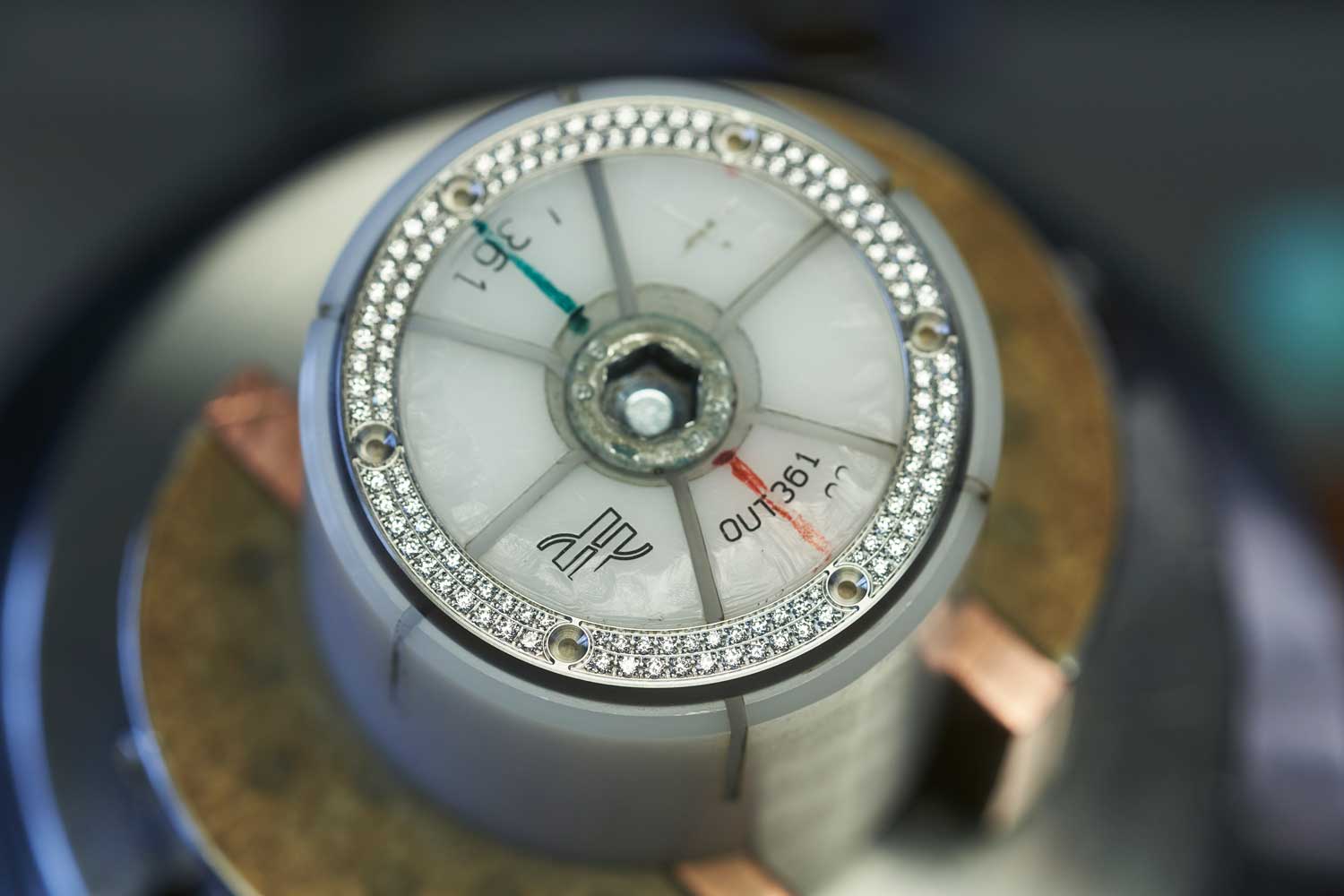

Intricate gem-setting process

Gem Setting the bezel of a watch

Examining the gem setting process

The Hublot team of developers work for the sheer joy of discovery, and are happy to partner with new ventures that offer opportunities to learn and to apply the expertise they have obtained through their research. With their dedication to R&D and their openness to collaboration, it’s no wonder that Hublot continues to lead the industry in new ways of using materials.

Design Evolution

Aside from Hublot’s use of space-age materials and ground breaking colors, the company is not afraid to play with the concepts of shape. In a world where most watches conform to the “round is right” shape for cases and dials, Hublot has plenty to meet the requirement with their iconic “porthole” models. However, they are also known for the unique tonneau, or “barrel,” cases that make their watches instantly recognizable to aficionados and collectors.

The movement for the Big Bang Tourbillon Samuel Ross

More recently, Hublot has introduced a new shape with the Square Bang Unico and Spirit of Big Bang Unico. While this may seem like a simple design update on the surface, changing the underlying movement architecture to fit the case is a technical hurdle that requires thought, planning and hard work for the watchmaking team. In fact, the square watches are skeletonized to showcase the new designs of the in-house Unico movement and celebrate the accomplishment.

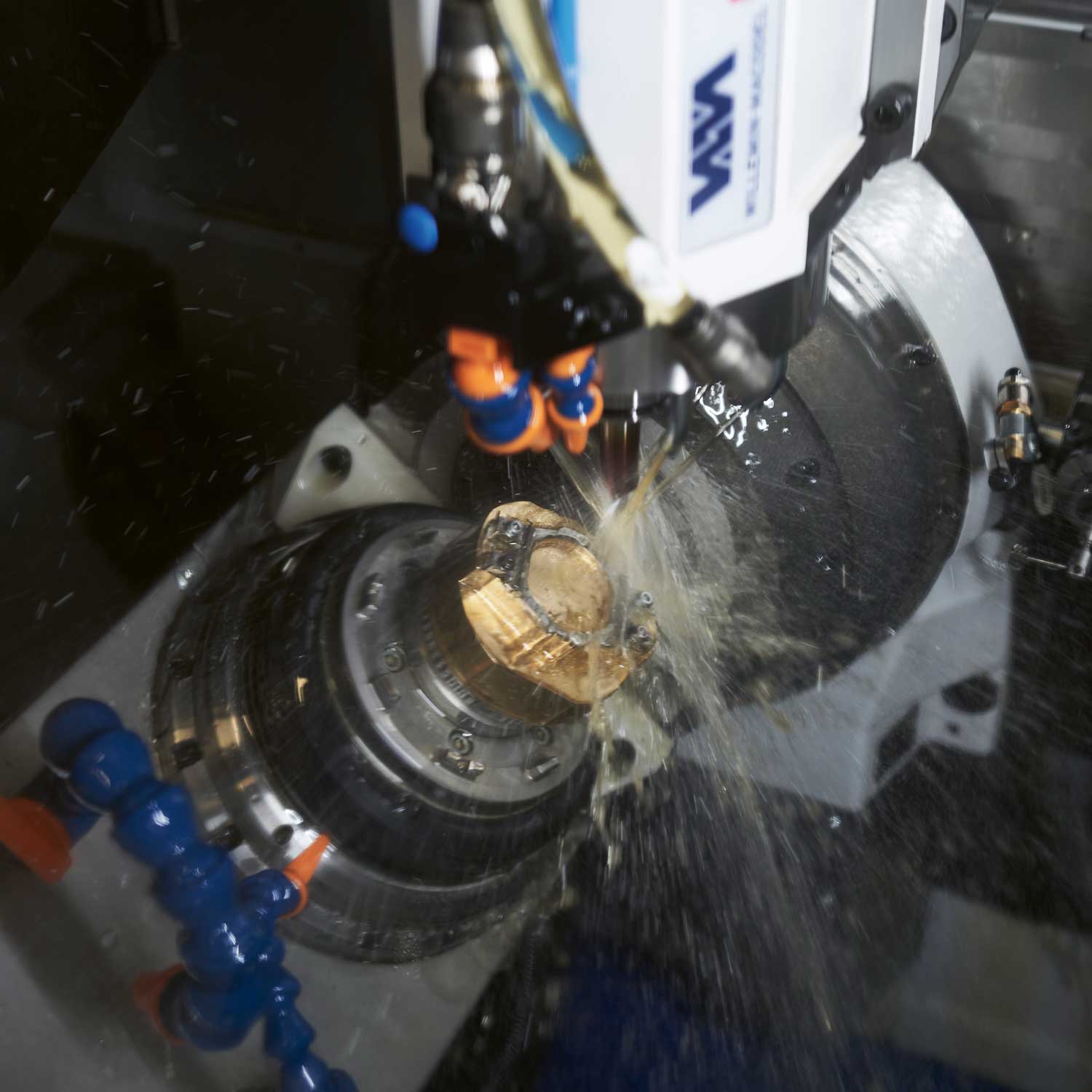

Machining process for the main plates of the UNICO movement

Machining a case component for the Square Bang Unico

Big Bang Unico upper plate case milling with a CNC machine

Leading Through Innovation

When it comes to innovation and experimentation, Hublot has been a leader since day one. With the “Art of Fusion” concept driving decisions and direction, and the R&D department working at full speed, there is seemingly no limit to where this brand will take the watch industry. It’s remarkable to see a company that commits to the development of new materials and techniques with a mind on the bigger picture rather than sales and commercial success. In their collaborations with scientists and artists, it’s clear that the team at Hublot are following their hearts in their discovery of new ways to solve difficult problems. With this attitude, the brand will continue to surprise and delight their loyal collectors and their partners for decades to come.