Reviews

A Visit to Tudor

Reviews

A Visit to Tudor

For decades, Tudor has struggled to establish an independent identity from big brother Rolex, but keeping its watchmaking so physically close serves a dual purpose, according to Tudor spokesman Christophe Chevalier. “We could have had a separate building with a big Tudor sign on top,” he says. “But having both brands under one roof sends out the message that we are a family.” While some may suggest that this is a complete reversal of past messages, it can also be seen as a signal that Tudor has found its strength in the modern world.

No longer regarded as just a more affordable add-on to its affiliated company, it is a powerhouse in its own right with a desirable and covetable selection of timepieces and a backstory to match that of any brand – a fact backed up by recent auction prices for early Tudor Submariners.

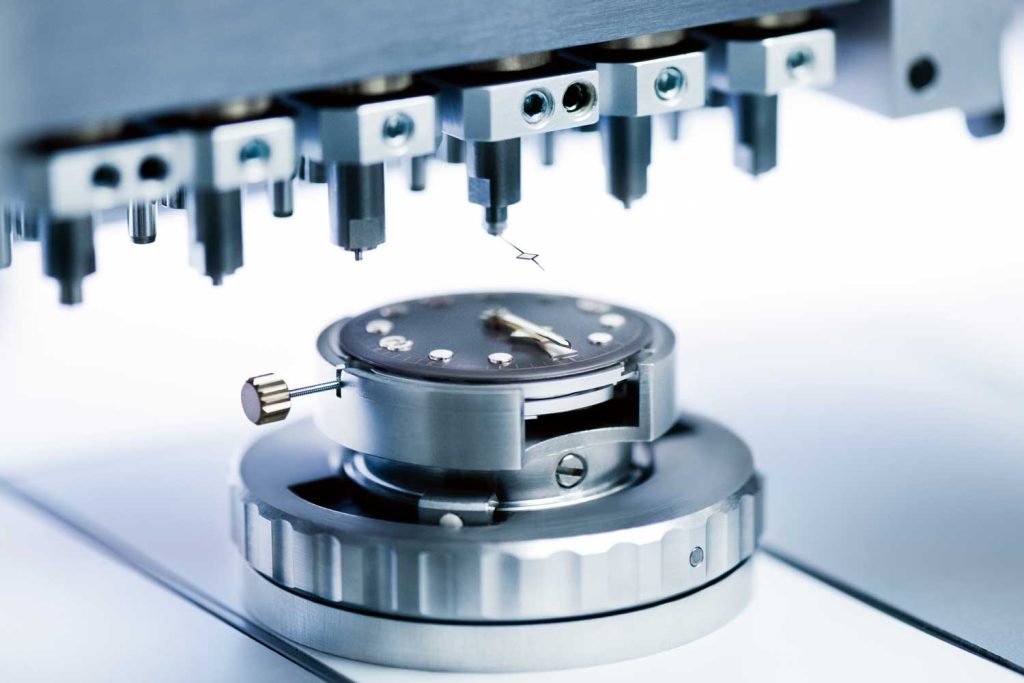

Black Bay hands waiting for assembly

The main goal across the board, from advertising to events to final product, is to reflect the overall philosophy of the watches – something unchanged since the very beginning. With the first advertising campaign for Tudor in 1952, there was no champagne-and-tuxedo feel; it was about function for blue-collar workers. That was the original message: a Tudor is a tool, not a status symbol, and a tool needs to be able to achieve what it was made for. “Our product is accessible and we always try to bring a young spirit,” says Chevalier. “That said, we have always been aspirational in our own way.”

Assembly of the hands

Research Post

One of the most interesting departments in the Tudor facility is that of R&D – a department that raises the question of whether the brand that prides itself on its tool watch reputation is looking at becoming more haute horlogerie. The first time R&D made its presence felt was with the reissued Advisor in 2011, with an alarm function fully developed in-house. Next came the manufacture calibre in 2015 and now it is modifications to this movement that is the department’s main job, demonstrated most recently in mid-size models, date versions and this year’s GMT. According to Chevalier, R&D is simply a necessary part of allowing Tudor to fulfill its promise to offer the best watch at the best possible price.

“We are constantly striving to find new solutions to offer greater horology to clients,” he says. “We don’t shy away from creative ideas. For us, it is all about the best solutions for our prerequisites of quality and flexibility.” And to this end, the column wheel chronograph calibre made in partnership with Breitling was not conceived to send a sensationalist message that Tudor was partnering with another brand, but rather, that it was using every avenue available to deliver incredible value at under CHF5,000. But, with the manufacture movements, Tudor wanted them to be certified chronometers to give buyers the added value they expect. The company has high demands, such as the 70-hour power reserve and the use of silicon for better precision, so in order to do this at the right price with the flexibility needed, Tudor had to have the capacity for in-house development.

Watchmaker testing functions after the dial and hands have been assembled

Watchmaker testing alignment of hands after complete assembly of the case

Holding Water

Historically, of course, dive watches have been a huge part of what Tudor stands for and water-testing is carried out fastidiously at the manufacture, something Chevalier describes as “a group approach”. After compression tests to measure water-tightness and submersion in a water tank – all pretty standard – every Tudor is subjected to a “thermos” test where a single drop of ice cold water is applied to the sapphire crystal of a heated watch. If the inside of the glass steams up, then there is a leak somewhere in the water-proofing. Any watch that survives this extensive protocol is unlikely to leak within the lifetime of its seals – currently at least 10 years.

Tudor Black Bay GMT batch being tested for water resistance

Thermic-shock test being carried-out on a Black Bay GMT to detect potential presence of moisture after a waterproof test

Top Strap

My Tudor trip ends with a whistle-stop trip to the French town of Saint Etienne to visit ribbon factory Julien Faure. Creating ribbons and trims for most of the top couture houses and luxury goods companies, the owners were approached several years ago by Tudor with one question: “Can you make a NATO-style strap?”

Assembly of the balance wheel

On the decision to pay the premium to have its fabric strap made by Julien Faure, Chevalier says: “Every part of our offering must match the technical and aesthetic refinements our watches offer. At Julien Faure, the fabrics are more complicated and expensive than a lot of other suppliers, but once you explain the story behind the factory and visit the manufacture, you just get it.”

Rotors waiting for assembly on the manufacture Calibre MT5402

Checking the freedom of the rotor of a manufacture Calibre MT5402