Grand Seiko

A Deep Dive into the Grand Seiko Caliber 9SA5

Grand Seiko

A Deep Dive into the Grand Seiko Caliber 9SA5

While it was initially available in two limited edition models, the caliber 9SA5 eventually made its way into a regular production model — the 2021 Heritage Collection’s SLGH005 — making the Grand Seiko Dual Impulse Escapement only the second non-Swiss-lever escapement to achieve series production in a wristwatch after the co-axial.

2021 Heritage Collection's SLGH005

But despite its excellent performance in the short term, its greatest Achilles’ heel is its need for lubrication. While the sliding friction generated at its contact points controls the unwinding force of the mainspring, it makes the surfaces vulnerable to wear and tear, rendering lubrication crucial. The inevitable deterioration of an applied lubricant in turn has adverse effects on accuracy. As such, many novel escapements in the market today serve to address this principal weakness, improving transmission efficiency and reducing power consumption in the process. But to supplant the lever escapement, the design of the new escapement ultimately requires a level of maturity and adaptability to industrial production on top of offering the additional advantage of the elimination or reduction of oil, making such an endeavor exceedingly difficult and a claim to fame when it yields results.

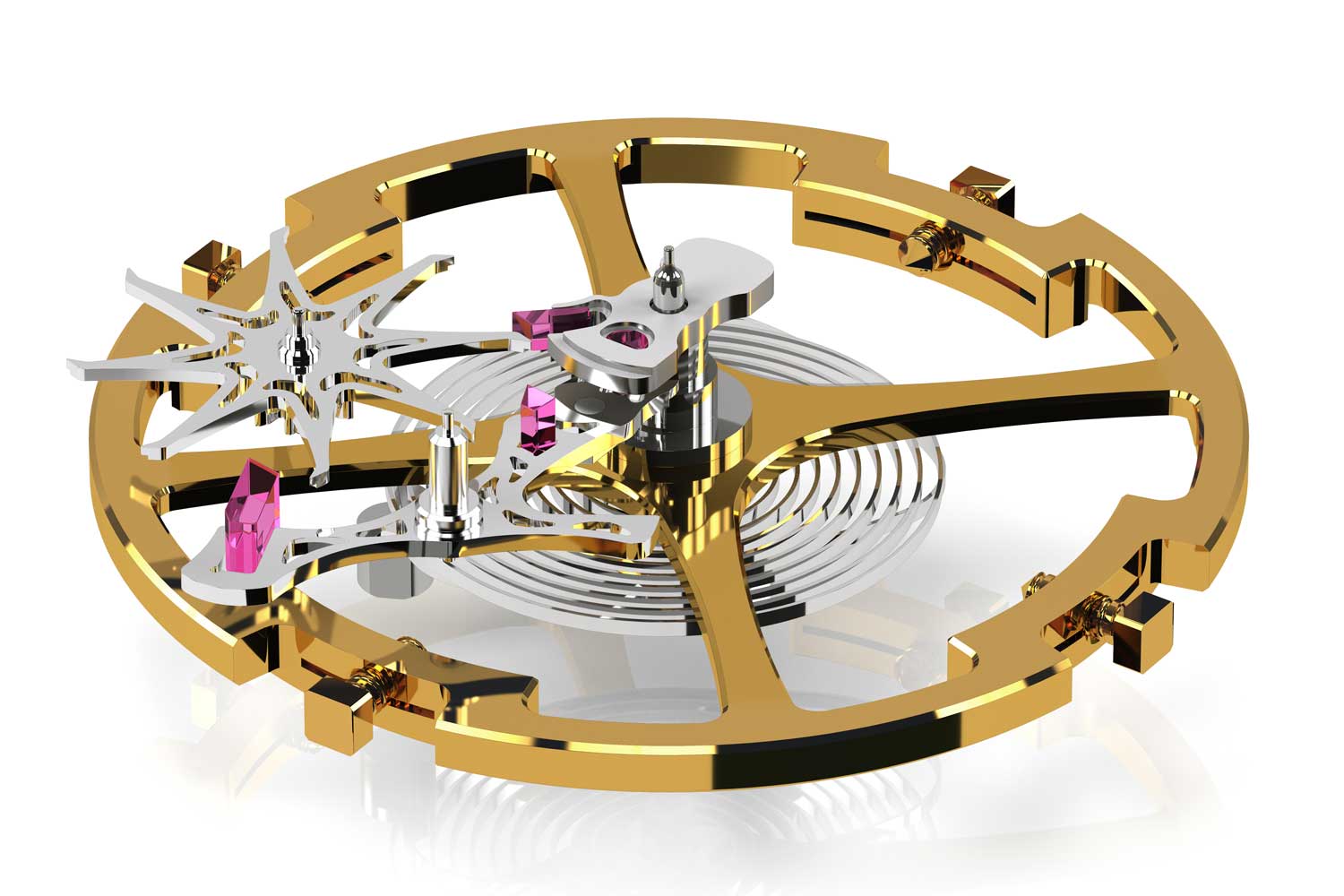

Dual Impulse Escapement

It is worth keeping in mind that an escapement, however intellectually exciting, does not operate in a vacuum. Apart from extending service intervals, the performance gains in an escapement can be used to improve the operational ability of other components, thereby providing tangible benefits to the wearer. It could be used to increase inertia/frequency of the balance or to extend power reserve.

Dual Impulse Escapement

The advantages of the co-axial escapement invented by George Daniels (1926–2011) are well-known, being the only alternative escapement to have been brought to an industrial reality until now. It successfully realized the merits of both the lever and detent escapements without either of their shortcomings. It is a dual impulse escapement that is self-starting while being oil free. The only downside is its relatively complex construction, necessitating a pair of co-axially mounted escape wheels which increases inertia and demands careful adjustments to ensure concentricity.

But while the lever escapement provides two impulses indirectly via a lever, the co-axial and the Dual Impulse provides an impulse to the balance directly in one direction and indirectly in the other via a lever. As such, both impulses could potentially vary in quality, though in practice, this is more abstract than a real-life problem.

In this regard, it is impossible to not mention the independent double-wheel escapement, created by George Daniels as a solution to the natural escapement that eluded Breguet. It is theoretically superior as two escape wheels impulse the balance in opposite directions directly, making its power delivery extremely efficient. However, the basic principles of this system, where each escape wheel necessitates its own gear train, proved limiting to the design of the movement as a whole, and the complexity of its construction makes it unsuitable for mass production.

While the co-axial and the Dual Impulse share the same basic principles in that one impulse is given directly, the indirect delivery is where they differ. While the co-axial operates completely oil-free, relying on radial impulse, the new escapement relies on a familiar sliding action to deliver impulse to the lever as with a Swiss lever escapement. This reintroduces the need for lubrication, albeit minimal — half that of the Swiss lever. As such, it offers far greater efficiency compared to the Swiss lever, while being simpler and less finicky than the co-axial, requiring just one escape wheel.

Crucially, the Dual Impulse Escapement was also designed to operate with low inertia. The pallet fork and lever are produced using a lithography technique known as MEMS (micro-electromechanical systems), allowing components to be fabricated with extreme precision, resulting in its intricate, skeletonized geometries that are lighter to ensure quicker acceleration of parts, which is crucial in a high-beat movement.

Balance and Hairspring

The low-inertia, low-friction Dual Impulse Escapement was used to achieve a longer power reserve as well as power a high-beat 5Hz balance wheel in the caliber 9SA5. A higher frequency offers greater stability for simple statistical reasons. Fluctuations are averaged over more oscillations per second and the less influence any given wrist motion can have on timekeeping.

Grand Seiko Caliber 9SA5

It also uses an overcoil hairspring, which is a traditional solution to improve isochronism. The labor involved in having to bend each hairspring by hand has made overcoils a rare sight in mass-produced movements. Grand Seiko, however, even designed and developed its own curve through over 80,000 computer simulations.

Barrel and Gear Train

The dimensions of the caliber 9SA5 also offer significant insight. It is slightly wider than the existing high-beat 9S85 to accommodate a pair of serially coupled barrels while being 15 percent slimmer at just 5.18mm high. This is achieved with thinner mainsprings. With a highly efficient escapement, the strength of the mainspring can be reduced to lessen the load and wear on the pivots and wheels, thereby extending service intervals and reducing running costs for the wearer. Additionally, the barrels are directly geared to each other as opposed to being connected via an additional wheel, further reducing wear.

Typically, in a movement with serially coupled barrels, the second wheel, which drives the minutes, is located in the middle, overlapping the barrel. But to reduce the height of the movement, the barrel drives a tiny second wheel located on the right of the movement when viewed from the caseback. With the fourth wheel located in the middle to drive the seconds directly, the barrel drives the motion works on the dial side. Therefore, no additional wheels are required to achieve a central seconds in this case, allowing the movement to be kept slim.

Beyond that, the design of the movement is as aesthetically pleasing as it is efficient, with a total of four beautifully shaped bridges as well as a skeletonized rotor, which allows the components to be seen.

It is not illogical, therefore, to say that the 9SA5 establishes for automatic movements what the recent Patek Philippe caliber 30-255 PS did for hand wound movements. By achieving the unusual feat of both a long power reserve and a high frequency/inertia while being slim and beautifully designed, they represent a new era of mass-produced movements that straddle both high performance and aesthetics like never before.